Precision composite material repair is crucial for vehicle safety and structural integrity. Advanced tools and techniques, like accurate geometry measurement, ensure high-quality outcomes, aesthetics, and long-term performance. This method offers cost savings by preserving original components, reducing downtime, and enhancing customer satisfaction in auto repair shops. Skilled technicians use specialized methods to accurately assess and mend damage, preventing future issues and ensuring vehicle reliability.

Precision in composite material repair execution offers significant advantages, from enhancing structural integrity to reducing costs and ensuring longevity. This article delves into three key benefits: how precision strengthens structures, its economic efficiency, and the role of quality restoration techniques in prolonging material lifespan. By adopting precise methods, professionals can deliver superior repairs, maintaining the performance and safety of composite materials across various industries.

- Enhancing Structure Integrity: Precision's Role

- Reduced Costs: Efficient Repairs Revealed

- Ensuring Longevity: Quality Restoration Techniques

Enhancing Structure Integrity: Precision's Role

Precision execution plays a pivotal role in enhancing the structure integrity of composite materials during repair processes. Composite materials, known for their unique properties like strength and light weight, demand meticulous attention to detail when damaged. Even minor inaccuracies can compromise the structural soundness, leading to potential failure points under stress or impact. Therefore, achieving precision in composite material repair is not just beneficial but crucial. It ensures that the repaired area matches the original material’s properties, maintaining overall vehicle integrity.

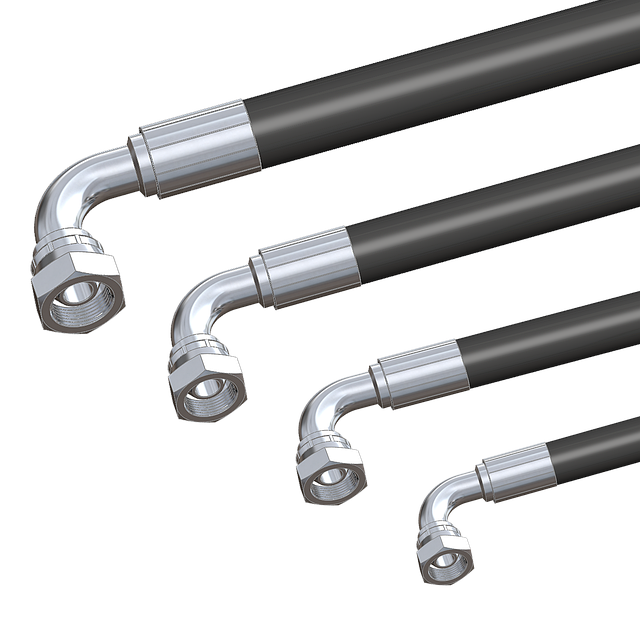

This precision involves using advanced techniques and tools tailored for composite materials. For instance, specialized equipment can accurately measure and reproduce complex geometries, ensuring perfect alignment of replacement parts. In the context of bumper repair or even car scratch repair, precision is key to restoring not just aesthetics but also structural integrity. Collision repair services that emphasize this precision can deliver high-quality outcomes, guaranteeing safety and performance over the long term.

Reduced Costs: Efficient Repairs Revealed

When it comes to composite material repairs, precision is key, and this attention to detail offers a significant advantage in terms of cost savings. Unlike traditional metal repairs, where replacements are often necessary, precise techniques for composite materials allow for efficient fixes that preserve the integrity of the original component. For example, in cases of car dent removal or hail damage repair on vehicles like Mercedes Benz, specialized tools and methods can restore the damaged area without having to replace the entire panel, reducing material and labor costs considerably.

This precision not only minimizes expense but also ensures faster turnaround times. Efficient repairs mean less down time for vehicles, which is particularly valuable in industries where mobile assets are crucial. By adopting precise composite material repair techniques, businesses can offer competitive pricing and quick service, gaining a competitive edge while keeping customers satisfied.

Ensuring Longevity: Quality Restoration Techniques

Precision is key when it comes to composite material repair, as it directly impacts the longevity and performance of the restored component. Skilled technicians employ advanced techniques to ensure every damaged area is accurately assessed and repaired, maintaining the structural integrity of the composite material. This meticulous approach involves using specialized tools and materials designed to match the original specifications, resulting in a seamless fusion that resembles the vehicle’s original condition.

In an auto repair shop setting, achieving precision in composite material repair is crucial for customer satisfaction and safety. For instance, in car bodywork restoration, precise repairs are essential to prevent future issues like water infiltration or structural weakness. This quality restoration ensures not only the aesthetics of the vehicle but also its overall reliability, providing drivers with peace of mind on the road.

Precision in composite material repair is not just a best practice—it’s a game-changer. By enhancing structure integrity, reducing costs, and ensuring longevity, this meticulous approach offers a superior alternative to conventional methods. Incorporating these quality restoration techniques not only benefits businesses but also promises a more sustainable future for composite materials, making it an essential consideration in the industry.