Collision frame repair, a vital process for vehicle safety, faces environmental challenges from waste generation and energy-intensive techniques. Auto professionals are adopting eco-friendly practices, such as recycling, alternative energy, and efficient frame straightening methods, to minimize these impacts. Traditional methods are being replaced by sustainable alternatives like water-based paints, advanced robotics, 3D printing, and recycling, reducing environmental impact and waste while combating global climate change, setting new standards for the industry including luxury brands like Mercedes Benz.

Collision frame repair, a common practice in the automotive industry, significantly impacts the environment. This article delves into the intricate world of collision frame repair, exploring its immediate and long-term environmental concerns. We dissect traditional repair practices, highlighting their hidden costs, and offer insights into sustainable alternatives that promise a greener future for this sector. Understanding these issues is crucial for both professionals and consumers alike, as we navigate towards eco-conscious solutions in the automotive landscape.

- Understanding Collision Frame Repair and Its Immediate Environmental Concerns

- The Hidden Costs: Long-Term Environmental Impact of Traditional Repair Practices

- Sustainable Solutions: Eco-Friendly Alternatives for Collision Frame Repair

Understanding Collision Frame Repair and Its Immediate Environmental Concerns

Collision frame repair is a specialized process that involves correcting and restoring structural damage to a vehicle’s frame after a collision. This type of repair is crucial for ensuring the safety and longevity of vehicles, as a solid frame acts as the car’s backbone, supporting various components and determining its overall stability. However, the environmental implications of collision frame repair work cannot be overlooked.

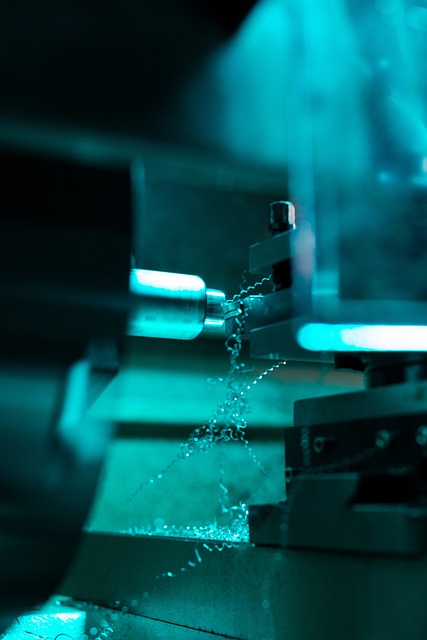

Immediate concerns include waste generation from removed or damaged parts, particularly metal panels and structural elements. Traditional methods often result in substantial amounts of scrap metal, contributing to environmental pollution if not properly managed. Additionally, the energy-intensive nature of collision frame repair processes, including frame straightening and welding, can have a significant carbon footprint. Auto maintenance professionals are increasingly adopting eco-friendly practices, such as recycling materials, using alternative energy sources, and implementing efficient techniques for frame straightening, to mitigate these environmental concerns associated with car body restoration.

The Hidden Costs: Long-Term Environmental Impact of Traditional Repair Practices

The environmental impact of collision frame repair goes beyond the immediate aftermath of an accident. Traditional repair practices, while effective in structural restoration, often come with hidden costs that can have long-term effects on the environment. The process typically involves extensive use of energy-intensive materials and techniques, contributing to greenhouse gas emissions and resource depletion. For instance, auto body work frequently relies on heavy metal fabrication, leading to increased carbon footprint due to mining, smelting, and refining processes.

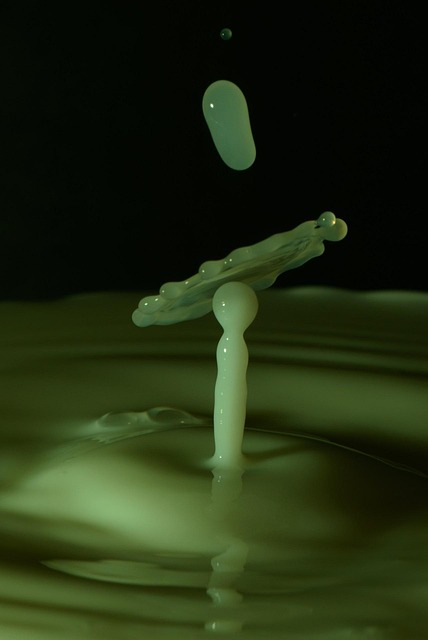

Additionally, improper disposal of hazardous waste generated during collision frame repair poses significant risks. Fluids like paint, solvents, and toxic chemicals from vehicle dent repair can contaminate soil and water bodies if not managed correctly. The long-term environmental consequences include pollution, habitat degradation, and potential health issues for both ecosystems and human communities surrounding repair facilities.

Sustainable Solutions: Eco-Friendly Alternatives for Collision Frame Repair

In the realm of collision frame repair, the quest for sustainable solutions has become increasingly vital. Traditional methods often involve resource-intensive processes and hazardous materials, leaving a significant environmental footprint. However, the automotive industry is witnessing a paradigm shift towards eco-friendly alternatives that not only reduce waste but also minimize the impact on both local ecosystems and global climate change. One notable example is the adoption of water-based paints and coatings in mercedes benz repair shops, which drastically cuts down on volatile organic compounds (VOCs) commonly found in conventional car paint services.

These sustainable solutions extend beyond mere painting techniques. Innovative technologies like advanced robotics and 3D printing are being employed to streamline collision frame repair processes, reducing the need for manual labor and minimizing material waste. Moreover, recycling and upcycling of automotive parts play a crucial role in fostering a circular economy, further mitigating the environmental impact of automotive repair. As these eco-friendly practices gain traction, they not only contribute to a greener planet but also set new standards for the future of collision frame repair across various vehicle makes, including luxury brands like Mercedes Benz.

Collision frame repair, while essential for vehicle safety, has historically carried significant environmental costs. By understanding the immediate and long-term impacts of traditional practices, we can appreciate the urgent need for sustainable solutions. Eco-friendly alternatives in collision frame repair offer a promising path forward, reducing waste, minimizing resource depletion, and lowering carbon footprints. Adopting these innovative methods not only benefits the environment but also contributes to a more resilient and responsible automotive industry.