Adhering to OEM guidelines is vital for auto repair shops using frame repair equipment, ensuring structural integrity, safety, and alignment with manufacturer specs. Right equipment includes precise measurement tools and advanced welding machines, promoting high-quality repairs, customer satisfaction, and vehicle resale value. Proper equipment maintains safety standards, enhances collision repair efficiency, and ensures vehicle structure integrity without compromising turnaround times.

When it comes to frame repair, equipment compliance with Original Equipment Manufacturer (OEM) guidelines is paramount. This ensures not only high-quality repairs but also safety and consistency across vehicle models. This article delves into the essential aspects of OEM guidelines for frame repair equipment, highlighting key components and the vital role proper equipment plays in achieving superior results. By understanding these standards, technicians can ensure their tools meet the stringent requirements for effective frame repair.

- Understanding OEM Guidelines for Frame Repair Equipment

- Key Components: What to Look for in Compliance

- Ensuring Safety and Quality: The Role of Proper Equipment

Understanding OEM Guidelines for Frame Repair Equipment

When it comes to frame repair equipment, adhering to OEM (Original Equipment Manufacturer) guidelines is paramount for auto repair shops and collision centers. These guidelines ensure that the repair process aligns with the manufacturer’s specifications, maintaining the structural integrity and safety of the vehicle. By following these standards, technicians can effectively perform complex frame repairs, ensuring vehicles return to their pre-accident condition.

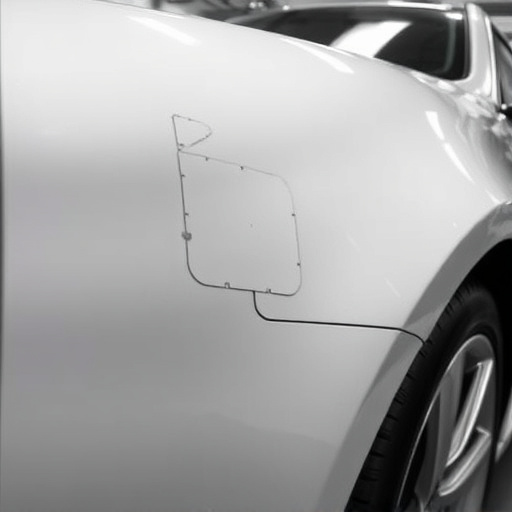

OEM guidelines cover a wide range of aspects, from specific tools and techniques to be used to precise measurements for adjustments. For instance, in a car collision repair scenario, equipment must be capable of accurately realigning metal panels and frames without causing further damage. This requires specialized machinery and skilled technicians who understand the intricacies of these guidelines, ultimately leading to better-quality repairs and customer satisfaction.

Key Components: What to Look for in Compliance

When selecting frame repair equipment, it’s paramount to focus on key components that ensure compliance with OEM (Original Equipment Manufacturer) guidelines. Look for robust and precise measurement tools like laser measures and digital calipers, which are essential for accurate alignment and structural integrity during auto glass repair or vehicle paint repair processes. These tools help in achieving the exact specifications set by the OEM, guaranteeing a seamless fit and finish comparable to the original equipment.

Additionally, consider advanced welding machines designed specifically for frame repair. These machines should offer control over heat input, allowing precise welding without damaging the surrounding components, which is critical in fleet repair services. Remember, adherence to OEM standards not only ensures the safety and quality of repairs but also maintains the vehicle’s resale value, a significant factor in the competitive market of frame repair equipment.

Ensuring Safety and Quality: The Role of Proper Equipment

Ensuring Safety and Quality: The Role of Proper Equipment

When it comes to frame repair, using the right equipment is paramount. Frame repair equipment plays a crucial role in maintaining safety standards and delivering high-quality collision repair services. Every piece of machinery should be chosen with care, adhering to Original Equipment Manufacturer (OEM) guidelines. These guidelines ensure that the tools align perfectly with the car manufacturer’s specifications, enabling precise frame straightening and restoration.

The reliability and accuracy of frame repair equipment directly impact the overall car restoration process. Proper equipment minimizes risks associated with human error, ensuring every adjustment is made with meticulous care. Moreover, it facilitates efficient work flow in collision repair shops, leading to faster turnaround times without compromising on the integrity of the vehicle’s structure.

When it comes to frame repair, using equipment that adheres to OEM guidelines is essential for ensuring the safety and quality of repairs. By investing in compliant frame repair equipment and regularly maintaining it, auto shops can provide reliable and durable solutions for their customers. Understanding these guidelines and selecting the right components are key steps in delivering top-notch automotive care.