Understanding common RV body damage is crucial for effective repairs, ranging from minor dents to severe structural failures. Specialized assessment includes thorough inspection for hidden vulnerabilities like leaks and rust. Top-notch repair uses advanced tools, durable materials, and techniques like panel beating and spot welding to restore structural integrity and aesthetic appeal. Expert restoration of curved panels and complex surfaces minimizes reliance on external services, focusing on unparalleled RV aesthetics through specialized techniques and technologies.

Uncover advanced tips and techniques for mastering RV body repair with this comprehensive guide. From understanding common damage types like dented panels, cracked fiberglass, and water damage to assessing and preparing surfaces, we cover it all. Learn about specialized tools and high-quality materials essential for successful repairs. Discover expert techniques for restoring curved panels and complex shapes, ensuring a seamless, durable finish. Elevate your RV restoration game with these innovative RV body repair strategies.

- Understanding RV Body Damage: Common Issues & Assessments

- Advanced Tools & Materials for Effective Repairs

- Expert Techniques: Restoring Curved Panels & Complex Surfaces

Understanding RV Body Damage: Common Issues & Assessments

Understanding RV Body Damage: Common Issues & Assessments

When it comes to RV body repair, understanding the common issues and damage patterns is the first step in ensuring effective repairs. RVs, with their diverse structures and exposure to varied environments, often face unique challenges. Common issues include dents from road debris, scrapes along sidewalls due to parking or narrow spaces, and even more severe damages like collisions or structural failures. Assessing these problems involves a thorough inspection that takes into account not just the visible damage but also potential hidden vulnerabilities.

For instance, while auto body shops might focus on surface-level repairs for cars, RVs demand a deeper look. Leaks, rust formation, and damage to water or sewage systems require specialized attention. Assessing these involves checking joints, seals, and underbelly components that are often overlooked but crucial to the overall integrity of an RV. Similarly, auto glass repair in an RV necessitates consideration of its larger size and unique installation methods, ensuring a secure fit that meets safety standards specific to these vehicles.

Advanced Tools & Materials for Effective Repairs

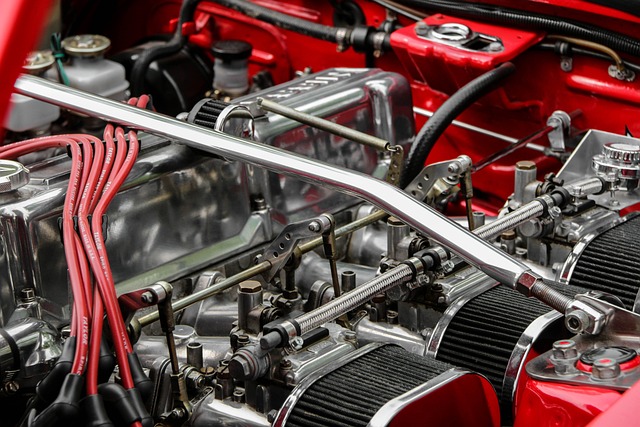

When it comes to RV body repair, having the right tools and materials is paramount to achieving professional results. Advanced RV repair technicians rely on a sophisticated set of tools tailored for the unique challenges presented by repairing recreational vehicles. These include specialized cutting tools, such as precision shears and high-quality blade sets, which enable clean and controlled cuts around intricate curves and tight spaces found in RV exteriors.

Additionally, modern RV body repair incorporates advanced materials designed to match the specific requirements of these vehicles. This encompasses not just durable and weather-resistant paints suitable for outdoor use but also specialized fillers and primers that bridge gaps and imperfections, ensuring a smooth base for application. The use of car bodywork techniques, like panel beating and spot welding, can further enhance structural integrity while restoring the RV to its original aesthetic appeal, effectively addressing vehicle paint repair needs specific to this mode of transportation.

Expert Techniques: Restoring Curved Panels & Complex Surfaces

When it comes to RV body repair, mastering the art of restoring curved panels and complex surfaces is a game-changer. These intricate areas, often found on the sides or rooflines of recreational vehicles, pose unique challenges due to their shape and design. Experts in RV body repair employ specialized techniques tailored to these specific needs. One such method involves precision mold making and custom fitting, ensuring an exact match for every curve and contour. By creating molds from original panels, they can reproduce even the most complex shapes, providing a seamless restoration.

Additionally, advanced technologies like computer-aided design (CAD) and 3D printing aid in this process. CAD software allows for precise measurements and virtual prototyping, enabling repair technicians to plan each step meticulously. This digital precision translates into physical accuracy when using 3D printers to create replacement parts or molds. With these expert techniques, tire services and auto painting become less of a concern, as the focus shifts towards restoring the RV’s original aesthetics with unparalleled craftsmanship and attention to detail.

RV body repair techniques have evolved to meet the unique challenges of restoring these versatile vehicles. By understanding common damage types, investing in advanced tools and materials, and mastering expert techniques like curved panel restoration, you can ensure your RV looks as good as new. Incorporating these tips into your DIY repairs or knowing when to seek professional help will extend the life of your recreational vehicle and enhance your adventures on the open road.