Modern auto body repair shops utilize diverse fastening techniques like rivets, bolts, adhesives, and mechanical systems to achieve high-quality repairs. Each method offers unique advantages and limitations, with adhesive bonding excelling in intricate finishes and mechanical fasteners providing precise solutions for luxury vehicles. Selection of the right auto body fasteners is crucial, considering damage extent, material type, desired strength, and environmental conditions, to ensure efficient and durable repair outcomes that meet pre-incident vehicle condition standards.

In modern collision repair shops, auto body fasteners play a crucial role in ensuring structural integrity and vehicle safety. This article explores the diverse types of auto body fasteners used today, delving into their unique advantages and disadvantages. By understanding the specific requirements of collision repair, professionals can choose the right fastener to achieve robust, long-lasting repairs. From traditional methods to innovative solutions, this guide provides valuable insights for optimal auto body restoration.

- Types of Auto Body Fasteners Used Today

- Advantages and Disadvantages of Common Fasteners

- Choosing the Right Fastener for Collision Repair

Types of Auto Body Fasteners Used Today

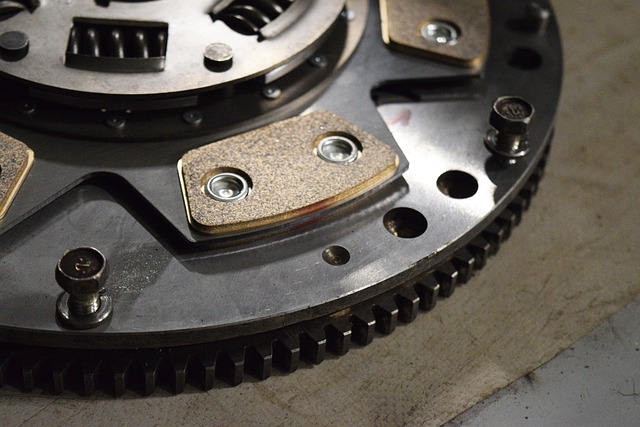

In modern auto body repair shops, a variety of auto body fasteners are employed to ensure precise and durable repairs. These include traditional methods like rivets and bolts, as well as more advanced options such as adhesive bonding and mechanical fastening systems. Rivets, for instance, have long been used in vehicle paint repair due to their strength and ability to create a strong bond between metal panels. Bolts, on the other hand, are versatile and suitable for both minor and major repairs, especially when reinforcing structural components.

For more complex and precise work, auto collision centers often utilize advanced mechanical fasteners. These can include clamps, crimps, and specialized tools designed for luxury vehicle repair. Adhesive bonding has also gained popularity due to its ability to create seamless joints, promoting both aesthetics and structural integrity. This technique is particularly beneficial in achieving a flawless finish, especially on intricate body panels, ensuring the restored vehicle looks as good as new.

Advantages and Disadvantages of Common Fasteners

Auto body fasteners play a pivotal role in modern collision repair shops, offering both advantages and disadvantages depending on their type. One significant benefit is their efficiency; common fastener options like rivets, welds, and self-tapping screws streamline the repair process by providing secure, durable bonds. These methods are particularly effective for structural repairs, ensuring the integrity of the vehicle’s frame and panels after collision damage repair.

However, each type also presents certain drawbacks. For instance, while rivets offer superior strength, they can be time-consuming to install due to the heat application required in the riveting process. Welds, on the other hand, demand specialized equipment and expertise, adding complexity to the auto body repair process. Self-tapping screws, though quick and versatile, might not provide the same level of structural stability as their more permanent counterparts, especially in severe collision damage repair scenarios. These considerations underscore the importance of choosing the right fasteners for specific applications within a car repair shop.

Choosing the Right Fastener for Collision Repair

Choosing the right auto body fasteners is a critical step in any collision repair process. With a wide array of options available, from traditional rivets and screws to modern adhesive and mechanical fastening systems, selecting the most suitable fasteners depends on several factors specific to each repair job. Key considerations include the type and extent of damage, the material being repaired (metal, plastic, composite), the desired strength and durability of the repair, and environmental conditions like temperature and humidity.

For instance, while screws and rivets offer excellent strength and are suitable for structural repairs, they may not be ideal for intricate, fine-detail work or materials that require flexibility. Adhesives provide a seamless bond but necessitate careful preparation and curing conditions. Understanding these nuances is essential for achieving precise, long-lasting results in automotive collision repair, ensuring vehicles return to their pre-incident condition or even surpassing it, making that auto repair near me a success story.

Auto body fasteners play a pivotal role in modern collision repair, offering efficient and durable solutions. By understanding the types, advantages, and disadvantages of each fastener, repair shops can make informed decisions to ensure high-quality repairs. When choosing the right auto body fasteners, considering factors like material compatibility, ease of installation, and long-term performance is essential for achieving optimal results in today’s automotive industry.