Frame rail replacement is a critical process in automotive repair, demanding skilled technicians and meticulous preparation. This involves inspecting and documenting frame damage, gathering necessary tools and parts, and creating a checklist for efficiency. Training plays a vital role through interactive learning, visual aids, case studies, regular assessments, and feedback, ensuring a competent workforce capable of high-quality frame rail replacement while adhering to safety standards.

Effective frame rail replacement is crucial for maintaining structural integrity and enhancing vehicle performance. This guide delves into the art of training staff for proficient frame rail replacement, ensuring safety and precision. We explore the intricacies of understanding frame rail systems, from their fundamental role in automotive construction to the specific challenges they present during repairs. By following a step-by-step approach and employing effective training techniques, shops can equip their workforce to execute frame rail replacements with confidence and efficiency.

- Understanding Frame Rail Systems and Their Importance

- Step-by-Step Guide: Preparing for Replacement

- Training Techniques: Ensuring Efficient Workforce Implementation

Understanding Frame Rail Systems and Their Importance

Frame rail systems are a critical component in automotive construction, forming the structural backbone of many vehicles. These intricate frameworks support the vehicle’s body, providing stability and rigidity during both static and dynamic conditions. Understanding the intricacies of frame rail replacement is paramount for any automotive technician or shop looking to offer top-tier vehicle body repair services.

In modern cars, frame rails are often designed with precision engineering, ensuring optimal performance and safety. They serve as a foundation for mounting various components, including the chassis, suspension, and drivetrain. During a frame rail replacement process, technicians must possess a deep knowledge of car bodywork services to accurately assess damage, disassemble affected sections, and install new or repaired rails, thereby ensuring the vehicle’s structural integrity and enhancing the overall quality of the car paint repair.

Step-by-Step Guide: Preparing for Replacement

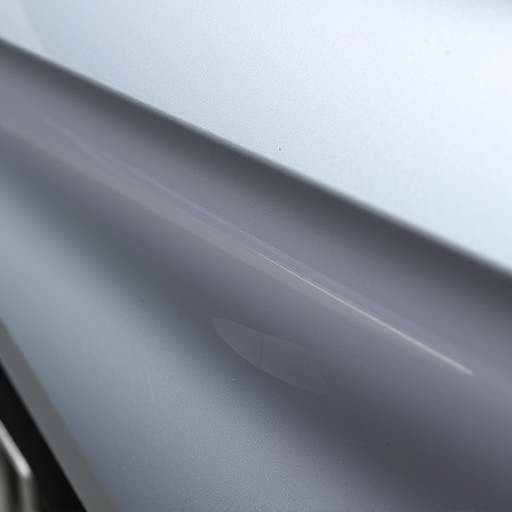

Before initiating any frame rail replacement, a meticulous preparation process is paramount to ensure the procedure’s success and the overall quality of car body restoration. Begin by thoroughly inspecting the existing frame for damage, corrosion, or deformities that might affect the replacement. This step involves checking for any loose components, identifying areas of concern, and documenting the condition of the frame using detailed photographs.

Next, gather all the necessary tools, equipment, and replacement parts specific to the frame rail replacement process. Ensure your automotive body shop is well-stocked with compatible frames, brackets, and any other required hardware. Create a comprehensive checklist to guide the team through each step, minimizing errors and ensuring every task is completed in order. This systematic approach facilitates a smooth transition from collision repair to precise frame rail replacement, ultimately enhancing the overall efficiency of car body restoration.

Training Techniques: Ensuring Efficient Workforce Implementation

Training is a pivotal aspect of successful frame rail replacement processes in both automotive body work and collision repair services. Efficient workforce implementation relies on effective training techniques that ensure every staff member understands their role, procedure, and responsibilities. Interactive learning methods are key; hands-on demonstrations and practical exercises allow trainees to gain real-world experience without immediate pressure. This ensures they grasp the intricacies of frame rail replacement, from initial assessment and disassembly to final alignment and reinstallation.

Using visual aids, case studies, and step-by-step guides can significantly enhance training outcomes. Breaking down complex tasks into digestible segments helps trainees stay focused and increases their confidence in handling frame rail replacements independently. Regular assessments and feedback sessions also play a crucial role, allowing trainers to identify knowledge gaps and provide targeted support where needed. This continuous learning approach fosters a competent workforce capable of delivering high-quality car paint services while ensuring customer satisfaction and safety standards are met.

Effective staff training is key to successful frame rail replacement, ensuring a seamless transition and minimizing disruptions. By understanding the importance of frame rail systems and employing efficient training techniques, businesses can confidently navigate the process. This step-by-step approach, outlined in this article, equips employees with the knowledge and skills needed for accurate and timely implementation, ultimately enhancing overall equipment effectiveness.