Safety sensor recalibration is vital for maintaining accurate data in adaptive systems, especially in ADAS and autonomous vehicles. Regular adjustments ensure sensors detect distances, obstacles, and road conditions precisely, influencing safety features like emergency braking and lane-keeping assist. This process is crucial in body shop repairs, preventing misjudged dents and enhancing cost-effectiveness through targeted recalibration strategies.

Safety sensor recalibration is a critical process ensuring adaptive systems remain accurate and reliable. In an era driven by advanced technology, these sensors play a vital role in everything from autonomous vehicles to industrial automation. This article delves into the essential practice of safety sensor recalibration, exploring its immediate benefits for accuracy and long-term impact on system performance. We’ll break down the key considerations and best practices for effective recalibration to help maintain optimal functionality.

- Understanding Safety Sensor Recalibration Needs

- The Impact of Regular Calibration on Accuracy

- Best Practices for Effective Recalibration Procedures

Understanding Safety Sensor Recalibration Needs

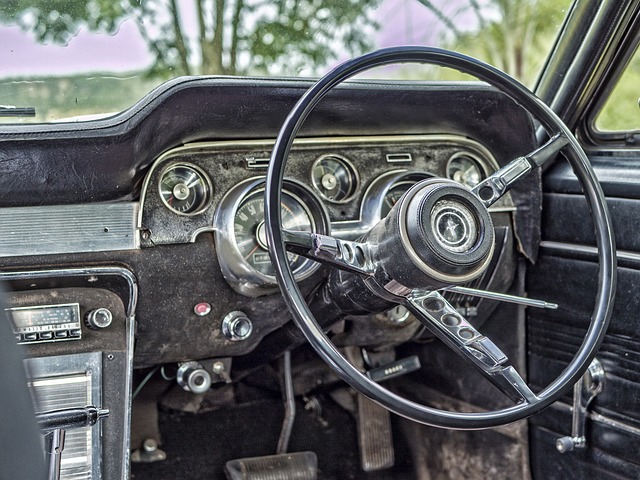

In the ever-evolving landscape of adaptive systems, ensuring accuracy is paramount for safe and efficient operation. Safety sensor recalibration plays a pivotal role in this pursuit. These sensors, integral to advanced driver assistance systems (ADAS) and autonomous vehicles, require periodic recalibration to maintain their integrity. This process involves re-evaluating and adjusting the sensor’s performance to account for any drift or changes over time.

Understanding the specific needs of safety sensor recalibration is crucial, especially in dynamic environments like vehicles. Regular calibration ensures that sensors accurately detect and interpret critical data points, such as distances, obstacles, and road conditions. This is particularly important in scenarios involving vehicle collision repair or scratch repair, where precise sensor readings can directly impact safety features like emergency braking, lane-keeping assist, and adaptive cruise control. Body shop services that incorporate meticulous safety sensor recalibration contribute to the overall reliability and performance of modern vehicles.

The Impact of Regular Calibration on Accuracy

Regular safety sensor recalibration is paramount for maintaining the accuracy of adaptive systems in various industries, including automotive repairs. Just as a painter would use a precise measuring tape to ensure their work lines up perfectly, so do sensors rely on calibration to deliver reliable data. Over time, these sensors can drift out of alignment, leading to inaccurate readings and subsequent issues with the system’s performance. For instance, in vehicle dent repair, where precision is key, an uncalibrated sensor could misjudge the extent of a dent, hindering the efficiency of paintless dent repair techniques.

This recalibration process involves regularly adjusting the sensors’ parameters to match their actual readings against known standards. By doing so, it ensures that adaptive systems, such as those used in fender repair, function optimally and provide accurate assessments. This is particularly crucial for advanced technologies like computer-aided design (CAD) systems that heavily rely on sensor data for precise repairs, ultimately enhancing the quality and speed of services offered in the automotive sector.

Best Practices for Effective Recalibration Procedures

Regular safety sensor recalibration is a best practice for maintaining the accuracy and reliability of adaptive systems in vehicles. It involves several key steps to ensure optimal performance. First, identify any deviations or anomalies during system operation, which could be caused by environmental factors, wear and tear, or damage. These issues often manifest as inaccuracies in sensor readings, leading to incorrect adaptive responses. Once identified, isolate the specific safety sensors requiring recalibration.

Next, use specialized diagnostic tools to verify the sensitivity, range, and accuracy of each sensor. Calibrate them according to the manufacturer’s guidelines, adjusting parameters like gain settings and offset values. After recalibration, conduct thorough testing in simulated or real-world scenarios to validate the system’s performance. This process ensures that safety sensors are functioning within specified tolerances, enhancing overall system integrity. For car body repair or vehicle paint repair cases where sensors might be affected by damage, a targeted recalibration strategy can help restore accuracy without unnecessary repairs, contributing to cost-effectiveness and faster restoration of adaptive system functionality.

Safety sensor recalibration is an essential practice for maintaining the accuracy and reliability of adaptive systems. By regularly calibrating sensors, we ensure that these systems make informed decisions based on accurate data, thereby enhancing overall performance and safety. Following best practices for recalibration procedures allows organizations to optimize their operations, reduce errors, and stay ahead in a rapidly evolving technological landscape.