TIG welding collision systems transform automotive repair with precision, speed, and cost-efficiency. Top-tier equipment and skilled technicians ensure superior dent repair outcomes while maintaining structural integrity and aesthetic appeal. Choosing a shop with these advanced systems offers efficient, versatile, and consistent results for diverse vehicle makes, revolutionizing both minor fixes and classic car restoration.

“Uncovering the secrets of top-notch welding equipment, this article guides you through the process of selecting shops armed with TIG welding collision systems. These advanced systems revolutionize precision and efficiency in metal fabrication.

We’ll explore the fundamentals of TIG welding collision systems, unraveling their intricate mechanisms. Subsequently, we’ll delve into key considerations when choosing the right equipment, highlighting essential factors to ensure optimal performance. Finally, discover the vast benefits and diverse applications of these cutting-edge systems.”

- Understanding TIG Welding Collision Systems

- Factors to Consider When Choosing Equipment

- Benefits and Applications of Advanced Systems

Understanding TIG Welding Collision Systems

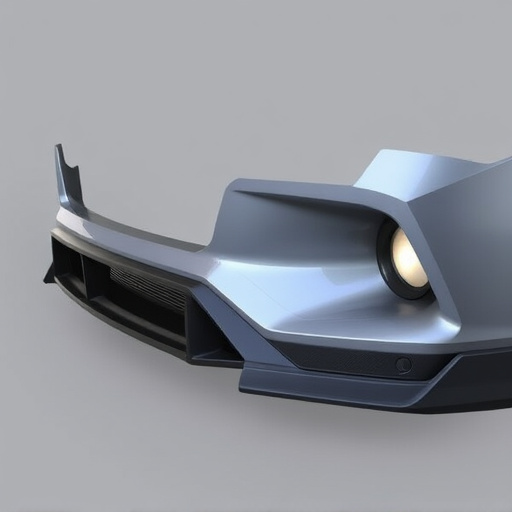

TIG welding collision systems are designed to address the unique challenges that arise during automotive collision repair, particularly in scenarios involving complex metalwork. These advanced systems utilize a TIG (Tungsten Inert Gas) welder, known for its precision and versatility, to accurately restore damaged vehicle components. By automating certain aspects of the welding process, these collision systems enhance efficiency while minimizing errors commonly associated with manual welding.

Understanding the intricacies of car dent repair or car dent removal is crucial when selecting a shop equipped with TIG welding technology. Collision repair services that incorporate such systems offer not just precision but also speed and cost-effectiveness. This modern approach ensures that damaged panels are seamlessly fused, maintaining the structural integrity and aesthetic appeal of the vehicle, ultimately delivering superior collision repair outcomes.

Factors to Consider When Choosing Equipment

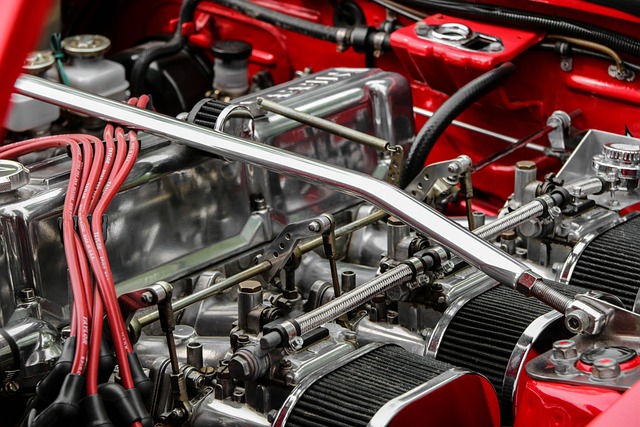

When selecting a shop equipped with TIG welding collision systems for your automotive collision repair needs, several factors come into play. Firstly, consider the type and quality of equipment available. Advanced TIG welding systems offer precise control and versatility, enabling skilled technicians to handle complex repairs and custom fabrications. Look for shops that invest in top-of-the-line machinery to ensure superior outcomes.

Additionally, evaluate the shop’s reputation and experience in automotive collision repair services. A well-established collision repair center with a proven track record of quality work is more likely to possess the expertise needed to handle various vehicle makes and models. Their proficiency in body shop services will guarantee that your car receives the meticulous attention required, from initial assessment to final restoration.

Benefits and Applications of Advanced Systems

Advanced TIG welding collision systems offer a multitude of benefits for shops specializing in car collision repair and fender bender fixes. These cutting-edge technologies streamline the process, enhancing efficiency while maintaining precision. By automating certain aspects of the welding process, these systems reduce human error, ensuring consistent and high-quality results. This is particularly beneficial for intricate metalwork, common in collision repair services, where accuracy is paramount.

Moreover, modern TIG collision systems can significantly speed up turnaround times without compromising on the final product’s integrity. They are versatile tools, applicable to a wide range of projects, from restoring classic car bodies to repairing minor dents and dings caused by everyday fender benders. This versatility makes them an invaluable asset for any shop looking to provide top-tier collision repair services.

When selecting shops for TIG welding collision systems, it’s crucial to consider equipment reliability, safety features, and the expertise of the workforce. By evaluating these factors, businesses can leverage the benefits of advanced TIG welding systems, including enhanced precision, efficiency, and reduced material waste. Investing in top-tier technology not only elevates quality but also fosters a safer, more productive work environment, ensuring long-term success in various industrial applications.