Spot welding systems are highly efficient tools for auto repairs, offering precise and strong bonding of metal components with minimal heat impact on surrounding materials. Ideal for collision repair shops and projects like panel replacement, paintless dent repair, and car dent repair, these systems preserve nearby components and reduce post-weld finishing needs. Automotive professionals favor them for their precision, speed, and efficiency in intricate restoration work, maintaining original aesthetics. The right spot welding system, selected based on material type, weld complexity, and workflow efficiency, ensures optimal performance and cost-effectiveness across various auto body repair tasks.

Spot welding systems have become indispensable in the automotive repair industry, offering a range of advantages over traditional joining methods. This article explores the benefits and applications of these innovative systems, providing a comprehensive guide for mechanics and DIY enthusiasts alike. From precise, fast welds to reduced material waste, spot welding offers efficient solutions for various auto repairs. Learn how to choose the right system for your needs and unlock the full potential of this powerful technology.

- Understanding Spot Welding Systems: A Basic Overview

- Benefits of Using Spot Welding for Auto Repairs

- Choosing the Right Spot Welding System for Your Needs

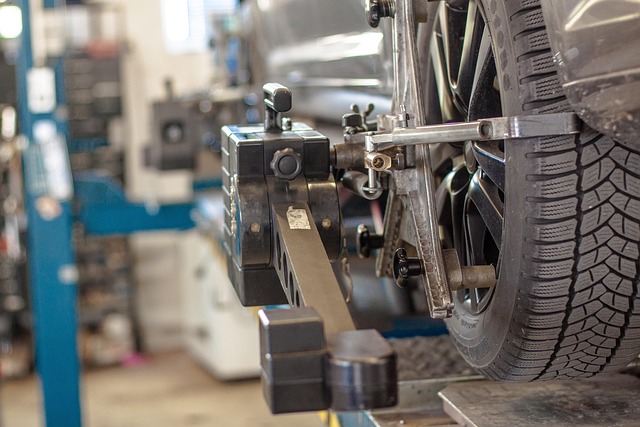

Understanding Spot Welding Systems: A Basic Overview

Spot welding systems are highly efficient tools used in auto repairs, offering precise and strong bonding of metal components. Unlike traditional welding methods, spot welding focuses energy on specific points to melt and fuse metals together, creating robust joints. This process is particularly beneficial for collision repair shops dealing with complex structural repairs.

By using controlled heat, these systems allow technicians to perform tasks such as panel replacement, paintless dent repair, and car dent repair with remarkable accuracy. The ability to target specific areas ensures minimal heat input into surrounding materials, preserving the integrity of nearby components and reducing post-weld finishing requirements. This makes spot welding a preferred method for achieving high-quality results in automotive restoration and modification projects.

Benefits of Using Spot Welding for Auto Repairs

Spot welding systems offer numerous advantages for auto repairs, making them a preferred choice among professionals in the automotive industry. One of the key benefits is their precision and speed. These systems allow for precise control over welds, ensuring clean and strong connections. This precision is particularly crucial when conducting intricate vehicle restoration work, where every detail matters to maintain the original aesthetics.

Additionally, spot welding is highly efficient for auto dent repair. It enables quick removal of dents and imperfections without causing further damage or leaving unsightly marks. Furthermore, spot welding facilitates seamless integration during auto body painting processes, as it creates strong bonds that withstand the rigors of repainting, ensuring a durable and professional finish.

Choosing the Right Spot Welding System for Your Needs

Selecting the ideal spot welding system is a crucial step for anyone involved in auto repairs and maintenance. These systems are versatile tools designed for specific applications, making it essential to match the right equipment with your requirements. Whether focusing on intricate bumper repair or tackling larger-scale auto body repair projects, understanding your needs is key.

Consider factors such as the type of material you’ll be working on (steel, aluminum, etc.), the complexity of the welds required, and the overall efficiency needed in your workflow. For instance, for precision work like fine auto maintenance, a smaller, handheld spot welder might be suitable, while heavier-duty projects like structural repairs may demand a more robust, industrial-grade system. Choosing wisely ensures optimal performance and cost-effectiveness for every auto body repair task.

Spot welding systems offer a host of advantages for auto repairs, from precision and efficiency to cost-effectiveness. By understanding the basics and choosing the right system for your needs, you can achieve high-quality, durable repairs. Incorporating spot welding into your auto repair arsenal is a smart move, ensuring stronger joints and faster turnaround times.