TIG welding auto body repairs offer numerous benefits over traditional methods, including precise and clean welds, structural integrity, long-lasting durability, and reduced heat input. This versatile technique joins various metal types accurately, preserving intricate designs and classic car shapes while minimizing repair times. TIG welding's consistent quality, risk reduction, and cost-effectiveness make it a preferred choice for auto painting, bodywork, and restoration services, enhancing vehicle value without visible weld marks.

TIG welding auto body repairs has emerged as a game-changer in the automotive industry, offering superior precision and quality. This article explores why TIG welding is the optimal choice for auto body work. By employing this advanced technique, professionals can achieve clean welds, enhanced structural integrity, reduced material waste, and faster turnaround times. Unlike traditional methods, TIG welding ensures versatility with various materials, while its strength and durability guarantee long-lasting repairs. Discover how this innovative process enhances both the functionality and aesthetics of vehicle restoration.

- The Advantages of TIG Welding for Auto Body Repairs

- – Precision and clean welds

- – Versatility in material types and thicknesses

The Advantages of TIG Welding for Auto Body Repairs

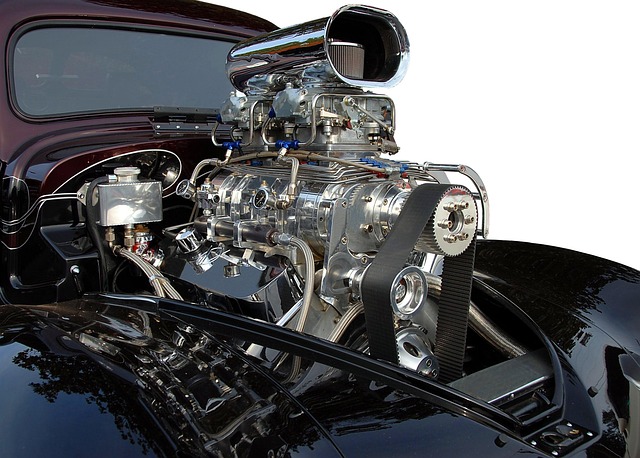

TIG welding auto body repairs offer numerous advantages over traditional methods, making it a preferred choice for many automotive professionals. This advanced technique allows for precise and clean welds, ensuring structural integrity and long-lasting durability in vehicle bodywork. The ability to join various metal types with exceptional accuracy means TIG welding is versatile, suitable for a wide range of car repair services.

One of its key strengths lies in the minimal heat input, resulting in less material distortion and preserving the original shape of the components. This precision is especially valuable when working on intricate designs or restoring classic cars where maintaining historical authenticity is paramount. Moreover, TIG welding produces consistent weld quality, reducing the risk of weak points or structural failures, which can be critical for safety and the overall performance of the vehicle. It also facilitates faster repair times without compromising on quality, making it a cost-effective solution for auto painting and bodywork services.

– Precision and clean welds

TIG welding auto body is renowned for producing precision and clean welds. This highly specialized technique, which stands for Gas Metal Arc Welding (GMAW), uses a non-consumable tungsten electrode to join metals together with minimal heat input. The result is a strong, precise bond that closely mimics the original metal structure, preserving the integrity of the auto body.

This precision is particularly beneficial in automotive repair and auto bodywork applications, where achieving clean lines and seamless joints is crucial. In an automotive body shop, TIG welding ensures that repairs are not only structurally sound but also aesthetically pleasing, maintaining the vehicle’s overall value and appearance. Its versatility allows for detailed work on intricate auto body components, making it a preferred method among professionals in the industry.

– Versatility in material types and thicknesses

One of the key advantages of TIG welding auto body for repairs is its versatility. This advanced technique can seamlessly join a wide range of metal types, from mild steel to aluminum and even stainless steel, making it an excellent choice for various vehicle restoration and auto detailing projects. Whether you’re repairing a classic car with thin, delicate panels or reinforcing a modern SUV’s frame with thicker metals, TIG welding offers the precision and flexibility needed.

Furthermore, TIG welding allows for precise control over heat input, enabling the manipulation of different metal thicknesses without compromising structural integrity. This makes it ideal for both intricate auto maintenance tasks that require fine detail work and robust repairs where strength is paramount. The result is a durable, aesthetically pleasing join that often leaves no visible signs of welding, enhancing the overall look and value of the vehicle in vehicle restoration efforts.

TIG welding auto body repairs offers a superior solution for precision and versatility, making it an ideal choice for professional mechanics. Its ability to produce clean, strong welds on various materials and thicknesses ensures high-quality results that last. By adopting TIG welding techniques, body shops can enhance their efficiency, reduce waste, and deliver top-notch finishes, ultimately satisfying customers seeking reliable and lasting repairs.