Spot welding equipment is a crucial asset for certified collision centers, enabling precise and efficient auto body repairs by creating strong, permanent metal bonds. Advanced models offer features like adjustable current control, digital displays, and real-time monitoring, enhancing repair quality and safety. Investing in top-tier equipment with precise parameter controls, modern features, and user-friendly design is essential for streamlining workflows, reducing cycle times, improving efficiency, and ensuring customer satisfaction in a competitive market.

In today’s automotive industry, certified collision centers require advanced spot welding equipment for precise and efficient repairs. Understanding the intricacies of spot welding equipment is essential for ensuring high-quality, safe, and cost-effective body shop operations. This article delves into the key components, features, and safety considerations for selecting top-tier spot welding equipment, equipping collision centers to deliver optimal performance. From powerful machines to user-friendly interfaces, discover what makes modern spot welding equipment indispensable in certified centers.

- Understanding Spot Welding Equipment: Essential Tools for Collision Repair

- Key Components and Features to Look For in Certified Centers

- Safety and Efficiency Considerations: Ensuring Optimal Performance

Understanding Spot Welding Equipment: Essential Tools for Collision Repair

Spot welding equipment is an indispensable component of any certified collision center, playing a pivotal role in precise and efficient auto body repairs. These specialized tools are designed to create strong, permanent bonds between metal panels, which is crucial for restoring vehicles to their pre-accident condition. The process involves focusing high-energy arcs to melt and fuse metal, creating robust welds that can withstand rigorous testing.

Certified collision centers require a range of spot welding equipment, including power supplies, guns, and consumables like electrodes and shielding gas systems. Advanced models offer features such as adjustable current control, variable voltage settings, and digital displays for precise welding parameters, ensuring top-quality auto repair shop operations. Effective utilization of this equipment not only expedites the collision center’s work but also contributes to the overall quality and safety of auto maintenance procedures.

Key Components and Features to Look For in Certified Centers

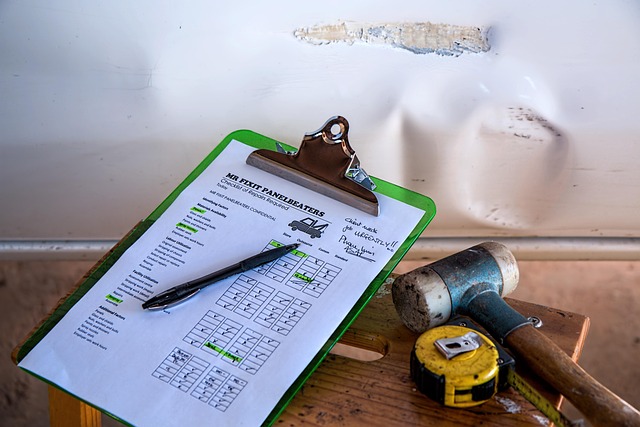

When setting up a certified collision center, investing in top-tier spot welding equipment is paramount. Look for machines that offer precise control over welding parameters like current, voltage, and pulse width, ensuring consistent and high-quality welds across various metal types and thicknesses—crucial for both structural integrity and cosmetic results in auto dent repair and vehicle body repair processes.

Modern spot welding equipment should be equipped with advanced features such as digital controls, automated settings for common metal combinations, and real-time monitoring capabilities. These functionalities not only streamline the workflow in collision repair shops but also contribute to enhanced precision, reduced cycle times, and improved overall efficiency. Additionally, consider models with interchangeable tips and adjustable foot pedals for ergonomic convenience during prolonged use.

Safety and Efficiency Considerations: Ensuring Optimal Performance

In the realm of certified collision centers, spot welding equipment plays a pivotal role in both safety and efficiency. When selecting or upgrading their tools, centers must prioritize machinery that delivers precise, consistent results while adhering to stringent industry standards for worker safety. This includes investing in high-quality, user-friendly equipment designed to minimize risks associated with arc welding, such as burn hazards and electrical accidents.

Moreover, efficient spot welding equipment streamlines the collision repair process, enabling technicians to work faster and more accurately. In a bustling car repair services environment where time translates directly to cost savings, modern, advanced machinery can significantly enhance productivity. This is particularly crucial in vehicle collision repair, where quick turnaround times are not just desirable but often necessary for customer satisfaction and business success.

Certified collision centers require robust spot welding equipment to ensure high-quality, safe, and efficient repairs. By understanding the essential tools, key components, and safety considerations outlined in this article, centers can invest in equipment that meets their specific needs. Choosing the right spot welding equipment is crucial for achieving precision, reducing downtime, and maintaining customer satisfaction in collision repair operations.