AI and digital practices revolutionize automotive diagnostics and repair, addressing critical repair quality concerns. AI analyzes vehicle data for predictive maintenance, identifying potential issues early. Real-time monitoring prevents equipment breakdowns, while open data sharing among manufacturers, shops, and consumers enhances repair accuracy from minor to complex work, boosting consumer satisfaction and peace of mind.

In today’s digital era, advances in technology are transforming the landscape of repair services. This article explores how cutting-edge innovations address crucial repair quality concerns. We delve into three key areas: AI Diagnostics for enhanced accuracy, Predictive Maintenance to prevent breakdowns, and Transparent Data Sharing to build consumer trust. By leveraging these advancements, industries can revolutionize their repair processes, ensuring higher satisfaction and reliability for customers while fostering a new level of transparency.

- AI Diagnostics: Enhancing Repair Accuracy

- Predictive Maintenance: Preventing Breakdowns

- Transparent Data Sharing: Building Trust in Repairs

AI Diagnostics: Enhancing Repair Accuracy

Artificial Intelligence (AI) is transforming the automotive industry, particularly in diagnostics and repair processes. AI algorithms can analyze complex data sets from vehicles, including sensor readings, images, and historical maintenance records, to predict potential issues before they become major repairs. By leveraging machine learning models, AI systems are becoming increasingly adept at identifying subtle defects or anomalies that may go unnoticed by the human eye. This capability is particularly beneficial for tasks like car paint repair and bumper repair, where precision is crucial.

For instance, AI can be trained to recognize patterns in car damage repair, enabling quicker and more accurate assessments. These systems can also suggest tailored solutions based on their analysis, improving overall repair quality. By minimizing human error and maximizing efficiency, AI diagnostics contribute significantly to addressing repair quality concerns, ensuring that vehicles are serviced to the highest standards.

Predictive Maintenance: Preventing Breakdowns

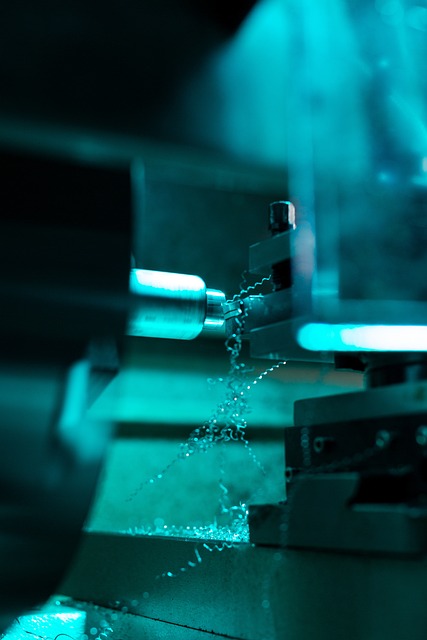

Predictive maintenance is a game-changer when it comes to addressing repair quality concerns. By leveraging advanced technologies like sensors and machine learning algorithms, manufacturers can now monitor equipment in real-time, detecting subtle changes in performance that may indicate an impending breakdown. This proactive approach allows for scheduled maintenance before failures occur, minimizing unexpected downtime and reducing the need for costly emergency repairs.

Imagine a factory floor where machines are equipped with smart sensors that continuously transmit data on their operational status. Any anomalies or deviations from normal patterns can be swiftly identified, enabling mechanics to take preventive action. For instance, in the realm of auto body repair and frame straightening, predictive maintenance can help identify structural weaknesses or fatigue points in vehicles, allowing technicians to address them before they lead to more severe damage. Even high-end brands like Mercedes-Benz collision repair facilities can benefit from these advancements, ensuring that every repair not only meets but exceeds quality standards.

Transparent Data Sharing: Building Trust in Repairs

In today’s digital age, the automotive industry is experiencing a significant shift towards transparent data sharing practices, which are instrumental in addressing repair quality concerns. By facilitating open communication and collaboration between manufacturers, repair shops, and even consumers, this approach builds trust and ensures that every party involved has access to accurate, up-to-date information about vehicle repairs. For instance, digital platforms enable the efficient exchange of detailed vehicle specifications, part replacements records, and troubleshooting guides, enhancing the accuracy and consistency of repairs, particularly in specialized areas like hail damage repair or auto glass replacement.

This transparency is not just beneficial for repairing minor dents and cracks but also extends to more complex tasks such as vehicle body repair. It empowers repair technicians with the knowledge they need to make informed decisions, ensuring that every fix adheres to manufacturer standards. Consequently, consumers can rest assured that their vehicles are in capable hands, leading to improved satisfaction and peace of mind, even when dealing with seemingly daunting repairs.

Advances in technology, such as AI diagnostics, predictive maintenance, and transparent data sharing, are significantly reducing repair quality concerns. By enhancing accuracy, preventing breakdowns, and building trust, these innovations ensure that repairs are efficient, reliable, and trustworthy. As technology continues to evolve, the future of repairs looks promising, offering improved outcomes for both consumers and service providers alike.