Specialty trim repair is a meticulous process focusing on restoring and replacing intricate vehicle components crucial for aesthetics and safety, common in luxury or custom cars. Using advanced tools like laser cutting and CAD systems, professionals achieve precise replication of original parts, enhancing vehicle design integrity. Efficient fabrication reduces labor costs, downtime, and customizes parts to unique needs, boosting customer satisfaction. Best practices involve understanding material properties and precision cutting methods; staying updated with industry trends like laser cutting for accurate car dent repair. Future trends include sustainable fabrication practices with eco-friendly materials, meeting the growing demand for high-quality auto detailing services.

In the realm of automotive restoration, specialty trim repair stands out as a precise and intricate process. This article delves into the pivotal role of fabrication techniques in enhancing the quality and efficiency of specialty trim repairs. From understanding the nuances of this specialized craft to exploring cutting-edge fabrication technologies, we offer a comprehensive overview. Learn how best practices and emerging trends are revolutionizing the landscape of specialty trim repair, ensuring superior results and optimal vehicle restoration.

- Understanding Specialty Trim Repair: A Comprehensive Overview

- The Impact of Fabrication Techniques on Repair Quality and Efficiency

- Best Practices and Future Trends in Fabrication for Specialty Trim Repairs

Understanding Specialty Trim Repair: A Comprehensive Overview

Specialty trim repair is a meticulous process that involves the skilled restoration and replacement of intricate vehicle components, often found in luxury or custom-built cars. These trim pieces, ranging from door handles to interior panels, not only enhance aesthetics but also contribute significantly to the overall safety and functionality of a vehicle. When damage occurs, whether due to accidents, wear, or theft, professional restoration becomes essential.

A comprehensive specialty trim repair process involves several steps, including assessment, disassembly, fabrication, and reinstallation. Skilled technicians utilize advanced tools and techniques to match original specifications precisely. In many cases, this includes reverse-engineering damaged parts to create molds for accurate reproduction. This level of craftsmanship is vital in maintaining the vehicle’s original design integrity, ensuring that every curve, contour, and detail is restored seamlessly, making it nearly impossible to distinguish repaired areas from the original factory components. Such meticulous attention to detail sets specialty trim repair apart from general car paint repair or collision repair services offered by typical vehicle body shops.

The Impact of Fabrication Techniques on Repair Quality and Efficiency

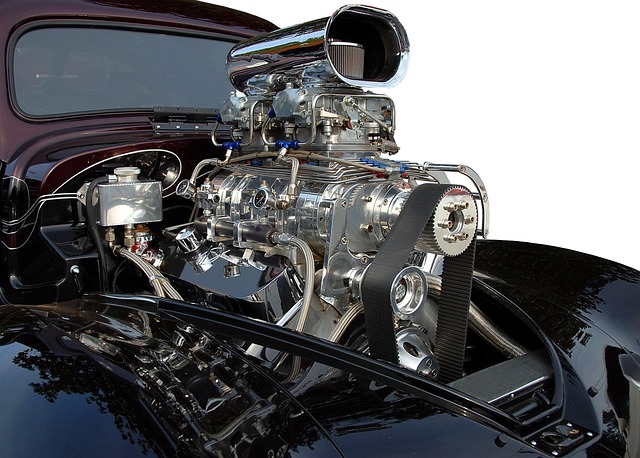

The choice of fabrication techniques plays a pivotal role in the quality and efficiency of specialty trim repair processes. Advanced technologies like laser cutting and computer-aided design (CAD) systems have revolutionized auto bodywork, enabling precise and intricate repairs that were once challenging. These methods ensure accurate measurements and smooth finishes, enhancing the overall aesthetics of the vehicle repair services.

In the realm of specialty trim repair, fabrication techniques directly influence the speed and precision with which damaged or worn-out components can be replaced. Efficient fabrication not only reduces labor costs but also minimizes downtime for customers. Moreover, modern fabrication processes facilitate the customization of parts, catering to unique design requirements in auto painting and bodywork projects. This level of customization ensures that vehicles regain their original look, enhancing customer satisfaction and the overall quality of repair services.

Best Practices and Future Trends in Fabrication for Specialty Trim Repairs

In the realm of specialty trim repair, fabrication plays a pivotal role in achieving precise and lasting results. Best practices involve utilizing advanced tools and techniques to mimic the original design seamlessly. This includes understanding material properties and employing precision cutting methods for car scratch repair and auto detailing. Staying ahead of industry trends is essential; adopting new technologies like laser cutting can enhance accuracy and efficiency, making it ideal for intricate car dent repair processes.

Looking towards the future, sustainable fabrication practices are poised to gain traction in specialty trim repairs. Eco-friendly materials and energy-efficient manufacturing methods will likely become more prevalent, aligning with global sustainability goals. As the demand for high-quality auto detailing services continues to grow, these innovations will ensure that fabrication techniques keep pace with the ever-evolving needs of the automotive industry, delivering superior results in car dent repair and beyond.

In conclusion, fabrication plays a pivotal role in enhancing the quality and efficiency of specialty trim repair processes. By understanding the impact of different techniques and adopting best practices, professionals can significantly improve outcomes. As the demand for specialized repairs grows, continued innovation and exploration of advanced fabrication methods will be essential to meet the evolving needs of this industry. Mastering these techniques ensures not only precise and durable repairs but also contributes to the overall sustainability and efficiency of specialty trim restoration efforts.