Modern steel panel construction in automotive manufacturing offers strength, durability, and lightweight properties. Steel panels protect vehicles from impact and corrosion. Advanced dent repair techniques like PDR preserve original paint, keeping high-end cars like Mercedes Benz in pristine condition. Technological advancements in laser imaging, CAD software, and robotic systems ensure precise dent fixing, minimizing waste and environmental impact. Future trends include lighter steel alloys and AI-driven diagnostics for even more efficient and sustainable car body repair.

In today’s world, advanced technology is transforming industries across the globe, and steel panel dent repair is no exception. Understanding modern steel panel construction is key to effective repair, as these panels are designed for strength and durability. This article explores traditional vs. advanced dent repair techniques, highlighting the evolution of technology in this field. We also delve into the future of steel panel dent repair, where innovative solutions promise faster, more efficient restoration processes.

- Understanding Modern Steel Panel Construction

- Traditional vs Advanced Dent Repair Techniques

- The Future of Steel Panel Dent Repair Technology

Understanding Modern Steel Panel Construction

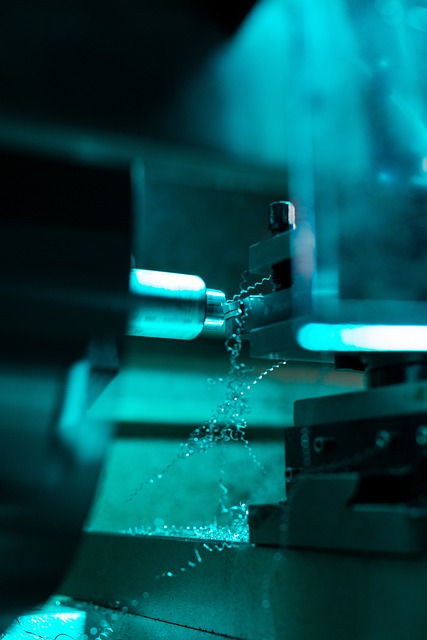

Modern steel panel construction involves intricate design and precision engineering, making it a popular choice for various applications, including automotive manufacturing. Steel panels are known for their strength, durability, and lightweight properties, which are essential in modern vehicle design. These panels form the exterior body of cars, trucks, and SUVs, offering excellent protection against impact and corrosion. The construction process involves advanced techniques such as deep drawing, stamping, and roll forming to create complex shapes with minimal material waste.

Understanding the intricacies of steel panel construction is crucial for effective steel panel dent repair. When a vehicle experiences a collision or accidental damage, it’s not just the visible dents that need attention but also the structural integrity of the panels beneath. Advanced technology in dent repair techniques, such as PDR (Paintless Dent Repair), leverages the original factory-applied paint system to minimize repainting requirements. This method is particularly effective for addressing minor car scratch repairs and dents, ensuring that Mercedes Benz repairs or any other high-end vehicle maintains its pristine appearance without excessive auto collision center visits.

Traditional vs Advanced Dent Repair Techniques

In the realm of steel panel dent repair, traditional methods have long been the go-to solution for many years. These techniques, though effective, often involve laborious processes that can be time-consuming and require significant manual labor. The advent of advanced technology has brought about a paradigm shift in this field, offering more efficient and precise methods for repairing steel panel dent damage.

Advanced dent repair techniques leverage cutting-edge tools and technologies, such as laser imaging, computer-aided design (CAD), and robotic arms, to accurately assess and rectify dents in vehicle bodywork. Unlike traditional methods that rely heavily on skilled technicians’ manual manipulation, these advanced approaches ensure consistent and high-quality results. Moreover, they reduce the need for excessive sanding and painting, minimizing both waste and environmental impact, making them a preferred choice in modern car collision repair and tire services.

The Future of Steel Panel Dent Repair Technology

The future of steel panel dent repair is promising, with technology rapidly advancing to meet the demands of both the automotive industry and consumers. Innovations such as robotic automation and advanced laser systems are already making inroads into car body repair workshops, offering precision and efficiency previously unattainable. These technologies can quickly and accurately assess dents, allowing for more effective and faster steel panel dent repair.

Furthermore, advancements in materials science are leading to the development of lighter, yet stronger steel alloys, which will require less intensive car dent removal methods. This, coupled with the integration of AI-driven diagnostic tools, promises a future where auto painting processes become more streamlined and environmentally friendly. The industry is moving towards sustainable practices, embracing digital solutions that enhance accuracy, reduce waste, and shorten turnaround times, ensuring a brighter and greener future for car body repair.

Advanced technology has revolutionized modern steel panel dent repair, offering efficient and effective solutions. By understanding the unique construction of steel panels and embracing innovative techniques, professionals can now achieve flawless results. As technology continues to evolve, the future of steel panel dent repair looks promising, with even faster, more precise methods on the horizon. This ongoing advancement ensures that both technicians and customers benefit from streamlined processes, superior quality, and enhanced durability in the repair of these versatile panels.