Ultrasonic dent detection is a revolutionary technology for vehicle repair, using high-frequency sound waves to uncover hidden dents beneath car paint, providing detailed images and data for precise damage assessment. This non-destructive method streamlines auto body restoration processes, reducing manual inspection time and labor costs, and resulting in faster turnaround times and higher-quality repairs. By integrating ultrasonic dent detection, vehicle body shops can enhance efficiency, minimize material waste, and offer more cost-effective car maintenance services, ultimately boosting customer satisfaction.

Ultrasonic dent detection is transforming retail operations by identifying subtle product defects invisible to the naked eye. This advanced technology employs high-frequency sound waves to detect imperfections in various materials, from plastics to metals. By integrating ultrasonic dent detection into quality control processes, retailers can achieve remarkable efficiency gains. The article delves into the technical intricacies of this method, explores its impact on reducing time and costs, and offers best practices for implementation, highlighting the future prospects of ultrasonic dent detection in enhancing shop productivity.

- Understanding Ultrasonic Dent Detection: A Technical Perspective

- The Impact on Shop Efficiency: Time and Cost Savings

- Best Practices and Future Prospects for Implementation

Understanding Ultrasonic Dent Detection: A Technical Perspective

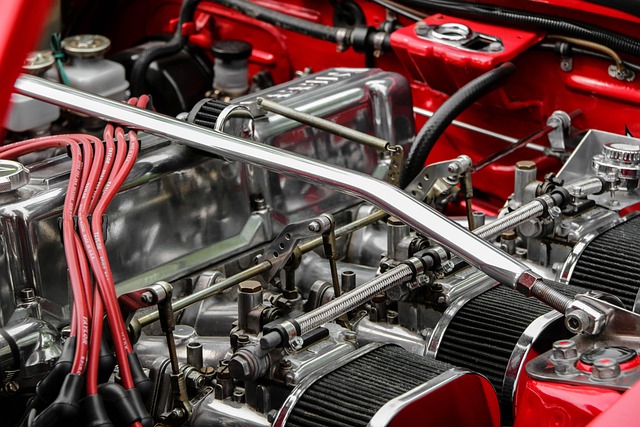

Ultrasonic dent detection is a cutting-edge technology that has revolutionized the way we assess and repair vehicle damage, particularly in car paint services and auto body restoration. This advanced technique utilizes high-frequency sound waves to penetrate and analyze the surface of vehicles, identifying even the most subtle dents or imperfections that might go unnoticed during visual inspections. By generating detailed images and data, ultrasonic dent detection provides an accurate and non-destructive method for assessing vehicle repair needs.

In the realm of vehicle repair, this technology plays a pivotal role in enhancing shop efficiency. It allows technicians to quickly and precisely locate and measure dents, streamlining the estimation process for car paint services and auto body restoration projects. With ultrasonic dent detection, shops can reduce the time spent on manual inspections, enabling faster turnaround times and improved productivity. This innovative approach ensures that every repair is carried out with precision, contributing to higher-quality outcomes in vehicle restoration.

The Impact on Shop Efficiency: Time and Cost Savings

Implementing ultrasonic dent detection technology has revolutionized vehicle dent repair processes, leading to significant time and cost savings for auto maintenance shops. This innovative approach streamlines the traditional frame straightening methods that were labor-intensive and time-consuming. With ultrasonic sensors, technicians can quickly and accurately identify dents, allowing them to focus on efficient repairs rather than extensive manual inspections.

The efficiency gains are substantial. Ultrasonic dent detection enables faster turnaround times for vehicle dent repair, as it minimizes the need for lengthy preparation and measurement stages. This, in turn, reduces operational costs by cutting down on labor expenses and material waste, making auto maintenance more cost-effective for both shops and customers alike.

Best Practices and Future Prospects for Implementation

Implementing ultrasonic dent detection technology is a game-changer for vehicle body shops and car bodywork professionals. Best practices involve utilizing this innovative tool as part of a comprehensive quality control process, ensuring precise measurements and accurate assessments. By integrating ultrasonic dent detection into their workflow, auto frame repair specialists can streamline operations, reduce human error, and enhance overall shop efficiency.

Looking ahead, the future prospects for this technology are promising. As advancements continue, ultrasonic dent detection systems will likely become more accessible, user-friendly, and integrated into existing vehicle body shop infrastructure. This evolution will further improve productivity, enable more complex repairs, and ultimately contribute to better customer satisfaction in car bodywork services.

Ultrasonic dent detection is a game-changer in enhancing shop efficiency, offering significant time and cost savings. By accurately identifying dental defects in materials, this technology streamlines quality control processes, reducing waste and minimizing rework. As best practices continue to evolve, adopting ultrasonic dent detection can drive operational excellence, ensuring shops remain competitive in today’s fast-paced manufacturing landscape.