Precision vehicle repair relies on advanced electronic measuring equipment for accurate panel gaps, paint thickness, and structural integrity, ensuring top-tier quality, aesthetics, and customer satisfaction in dent repair, car restoration, and auto painting.

In today’s precision-driven world, electronic measuring equipment is indispensable for ensuring quality repairs across various industries. This article delves into the transformative impact of such technology on repair processes. We explore three key aspects: precision measurement as the foundation of quality, advanced technology boosting efficiency and accuracy, and the vital role of calibrated equipment in maintaining consistency. By understanding these elements, we can appreciate how electronic measuring equipment acts as a game-changer in repair quality.

- Precision Measurement: The Cornerstone of Quality Repairs

- Advanced Technology: Enhancing Efficiency and Accuracy

- Ensuring Consistency: The Role of Calibrated Equipment

Precision Measurement: The Cornerstone of Quality Repairs

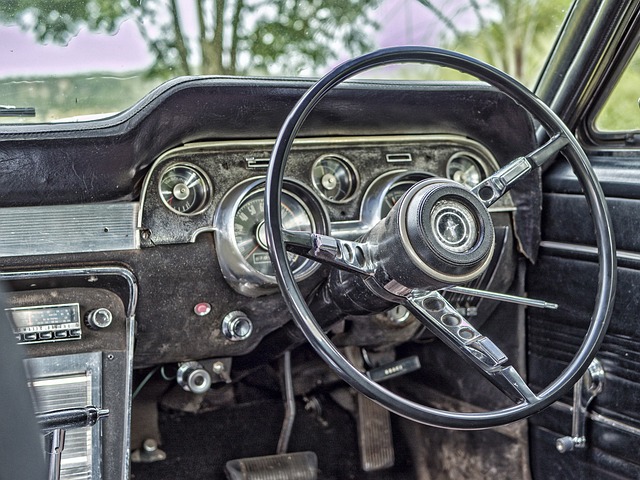

Precision Measurement plays a pivotal role in achieving exceptional repair quality, and electronic measuring equipment is the cornerstone of this process. These advanced tools provide exacting measurements, ensuring that every detail, from panel gaps to paint thickness, meets stringent standards. In the realm of vehicle dent repair, car restoration, and auto painting, even the slightest deviation can impact the final result.

Electronic measuring equipment offers unparalleled accuracy, enabling technicians to identify and rectify defects before they become visible or structural issues. This level of precision not only enhances aesthetics but also guarantees long-lasting durability. By leveraging these tools, repair professionals can confidently restore vehicles to their original condition, ensuring customer satisfaction in every car restoration and auto painting project.

Advanced Technology: Enhancing Efficiency and Accuracy

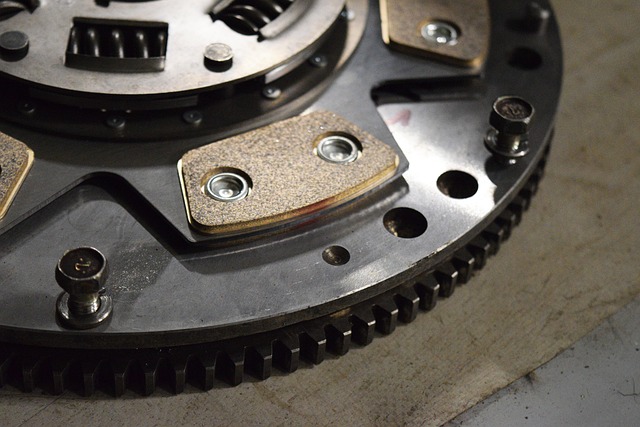

In today’s advanced automotive industry, electronic measuring equipment has become an indispensable tool for achieving superior repair quality. These innovative devices leverage cutting-edge technology to offer unprecedented levels of precision and efficiency in various aspects of automotive restoration and collision center operations. By integrating sophisticated sensors and software algorithms, they can accurately assess damage, measure crucial dimensions, and guide frame straightening processes with remarkable consistency.

This technological advancement is particularly evident in the realm of frame straightening, where electronic measuring equipment plays a pivotal role. In a collision center setting, precise measurements are crucial for ensuring that vehicles return to their original factory specifications after repairs. These tools enable technicians to detect even subtle misalignments, facilitating more effective and efficient adjustments during the frame straightening process. This, in turn, leads to improved overall repair quality, customer satisfaction, and reduced cycle times for collision centers.

Ensuring Consistency: The Role of Calibrated Equipment

Achieving consistent and high-quality repairs in auto body services, including vehicle dent repair and fender repair, relies heavily on the accuracy and reliability of electronic measuring equipment. Calibrated tools play a pivotal role in ensuring that every repair is executed with precision, adhering to strict industry standards. By regularly calibrating these devices, technicians can accurately measure and monitor critical dimensions, angles, and distances throughout the repair process.

This attention to detail is paramount, as even minor inconsistencies can impact the overall quality of work. Calibrated equipment allows for precise adjustments during repairs, whether it’s aligning panels in vehicle dent repair or ensuring proper paint application in fender repair. Consequently, it helps reduce errors, saves time, and ultimately contributes to the satisfaction of customers who expect flawless auto body services.

Electronic measuring equipment plays a pivotal role in ensuring repair quality. By facilitating precision measurement, advanced technology, and consistent performance through calibration, these tools enable technicians to deliver accurate and reliable repairs. Investing in high-quality electronic measuring equipment is not just an upgrade; it’s a strategic move towards enhancing overall repair efficiency and customer satisfaction.