The PDR process (Paintless Dent Repair) is a game-changer in automotive dent repairs, offering swift, cost-effective solutions for various damage, especially hail damage. This technique preserves vehicles' original finishes, reduces repair times, and minimizes disruption to customers' schedules. Skilled technicians use specialized tools like plastic deformation and air compression for precise repairs, from minor scratches to significant collision damage. PDR is an eco-friendly alternative, reducing energy consumption and waste, making it ideal for Mercedes Benz repair services as environmental awareness grows.

“The future of dent repair is here, and it’s called PDR (Paintless Dent Repair). This innovative process is revolutionizing the automotive industry by offering efficient, precise, and eco-friendly solutions. In this article, we explore how PDR provides significant time savings compared to traditional methods, while showcasing its artistic precision and minimal environmental impact. Discover why PDR is becoming the preferred choice for both professionals and car owners, unlocking a new level of convenience and sustainability in dent repair.”

- Unlocking Efficiency: PDR's Time-Saving Advantages

- The Art of Repair: PDR Techniques and Precision

- Environmental Impact: PDR's Eco-Friendly Approach

Unlocking Efficiency: PDR's Time-Saving Advantages

The PDR process, or Paintless Dent Repair, is revolutionizing the automotive industry by offering a highly efficient and time-saving solution for both minor and significant dent repairs. Unlike traditional collision damage repair methods that often involve extensive painting and body work, PDR focuses on restoring the vehicle’s original appearance without disturbing the factory finish. This innovative technique not only reduces the amount of time required to fix dents but also minimizes costs for both automotive body shops and their customers.

Hail damage repair, a common concern for many vehicle owners, benefits greatly from the PDR process. Its non-invasive nature means that repairs can be completed quickly, with minimal disruption to the customer’s schedule. This efficiency is particularly appealing in high-volume automotive body shops where turning vehicles around promptly is crucial for maintaining productivity and customer satisfaction. By adopting the PDR process, these shops can streamline their operations, enhance service quality, and stay competitive in a crowded market.

The Art of Repair: PDR Techniques and Precision

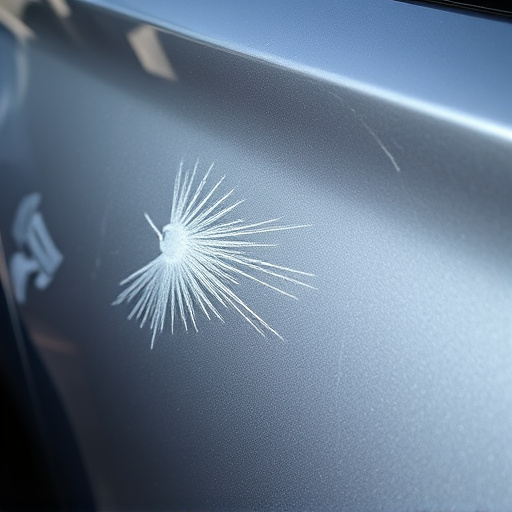

The PDR process is an art that combines skill, precision, and a deep understanding of materials. It involves repairing dents and damage to vehicle bodies with minimal painting, often restoring them to their original condition. Technicians use specialized tools and techniques, such as plastic deformation and air compression, to manipulate the metal without compromising its integrity. This meticulous approach allows for intricate repairs, from minor scratches to significant collision damage, ensuring vehicles look like new.

Precision in PDR is key to achieving high-quality results. Skilled technicians can address various issues, including dent removal, crease repair, and even auto glass replacement. The process demands a keen eye for detail and the ability to navigate complex shapes and contours, especially when dealing with curved surfaces. With steady hands and specialized equipment, PDR masters transform damaged cars, offering an alternative to costly full paint jobs. This method not only conserves resources but also reduces the time spent in collision repair centers, making it a preferred choice for many car owners seeking top-notch scratch repair.

Environmental Impact: PDR's Eco-Friendly Approach

The PDR process is a game-changer when it comes to environmental sustainability within the automotive industry, especially for mercedes benz repair and vehicle bodywork. Traditional dent repair methods often involve harmful chemicals and extensive use of resources, contributing to a significant carbon footprint. However, paintless dent repair (PDR) offers an eco-friendly alternative that minimizes these adverse effects.

By utilizing specialized tools and techniques, PDR professionals can effectively restore vehicle bodywork without the need for costly repainting or hazardous materials. This method not only reduces waste but also saves energy, making it a more sustainable solution. As environmental consciousness grows, the PDR process is poised to become the preferred choice for eco-conscious consumers seeking mercedes benz repair services, ensuring that their vehicles are restored with a minimal ecological impact.

The future of dent repair is here with the PDR process, offering a seamless blend of efficiency, artistry, and environmental sustainability. By embracing advanced techniques and eco-friendly practices, PDR stands as a game-changer in the automotive industry. Its time-saving advantages, precision repairs, and minimal waste make it an unparalleled choice for both professionals and consumers seeking top-notch dent restoration. Embracing the PDR process is not just a step forward; it’s a leap towards a greener, more proficient future of vehicle upkeep.