Before recalibrating safety sensors, understand key performance metrics like sensitivity, accuracy, response time, and reliability to set benchmarks for flawless operation during vehicle repairs. Prepare meticulously by gathering equipment, identifying interfering factors, and ensuring accurate repairs. Follow manufacturer guidelines strictly, document adjustments, and maintain peak sensor efficiency for enhanced vehicle safety.

Ensure optimal safety system performance with a systematic approach to verify successful safety sensor recalibration. Before, during, and after recalibration, understand key metrics, prepare your workspace, and identify potential interfering factors. Follow manufacturer guidelines rigorously, documenting each step and result for future reference. This meticulous process guarantees precise sensor functionality, enhancing overall system reliability and worker safety.

- Understand Sensor Performance Metrics Before Recalibration

- Prepare for Calibration: Gather Tools and Identify Interfering Factors

- Execute Recalibration Following Manufacturer Guidelines and Document Results

Understand Sensor Performance Metrics Before Recalibration

Before attempting a safety sensor recalibration, it’s crucial to grasp the key performance metrics associated with these sensors. Understanding how your vehicle’s safety systems interpret and respond to data from these sensors is fundamental. Metrics like sensitivity, accuracy, response time, and reliability are critical indicators of sensor health. For instance, a sensor’s ability to detect minute changes in proximity or pressure variations can impact its overall effectiveness during an emergency braking event or collision avoidance.

Knowing the typical performance ranges and acceptable deviations for each metric allows you to set clear benchmarks for recalibration success. This knowledge is especially relevant when it comes to tasks like vehicle body repair, scratch repair, or paintless dent repair—where precise sensor function is paramount to ensuring safety features operate flawlessly.

Prepare for Calibration: Gather Tools and Identify Interfering Factors

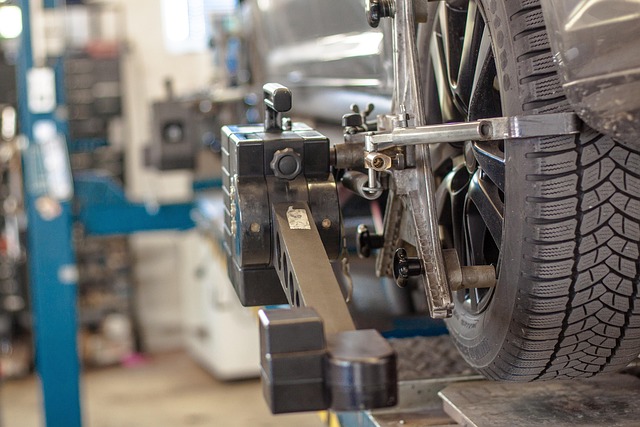

Before initiating the safety sensor recalibration process, it’s essential to prepare meticulously. This involves gathering the necessary tools for the task, which may include specialized equipment unique to your vehicle model and calibration standards provided by the manufacturer. Additionally, identifying potential interfering factors is crucial. These could range from external environmental conditions like magnetic fields or temperature fluctuations to internal components that might impact sensor accuracy. In a collision repair shop or collision repair center, where these sensors are often critical for safety features, ensuring that all repairs and replacements have been completed accurately and that no foreign objects are compromising the sensor’s function is paramount. Vehicle repair services should also consider the allocation of dedicated space free from these interferents for the recalibration process to guarantee precise results.

Execute Recalibration Following Manufacturer Guidelines and Document Results

Following manufacturer guidelines is a critical step in ensuring successful safety sensor recalibration. This process typically involves specific procedures and parameters designed to optimize sensor accuracy. Every vehicle, and by extension, its safety sensors, is unique, so adhering to the manufacturer’s protocols guarantees that the recalibration is tailored to meet the exacting standards of the original equipment.

After executing the recalibration according to these guidelines, it’s essential to document the results. This includes recording any adjustments made, as well as the sensor’s performance metrics before and after recalibration. Such documentation not only serves as a reference for future comparisons but also plays a crucial role in collision damage repair and frame straightening processes, ensuring that safety sensors function at peak efficiency for enhanced vehicle safety.

To ensure a successful safety sensor recalibration, understanding key performance metrics, preparing adequately, and adhering strictly to manufacturer guidelines are essential steps. By accurately documenting results, you can verify the effectiveness of the recalibration process, enhancing overall system reliability and safety. Regular recalibrations, as recommended by manufacturers, are crucial for maintaining optimal sensor performance in dynamic environments.