Digital measuring systems revolutionize automotive restoration and collision repair, offering unparalleled precision, speed, and efficiency. They replace manual measurements with 3D scans, enhancing productivity, quality, and customer satisfaction by automating data capture and analysis for accurate repairs, reducing errors, and expediting turnaround times.

In today’s competitive landscape, investing in digital measuring systems is no longer an option—it’s a necessity. These advanced technologies are transforming industries by enhancing precision and efficiency in measurement processes, automating tasks that were once manual, and enabling data-driven decisions. From manufacturing to healthcare, the applications of digital measuring systems are vast and impactful. Discover how these innovations are revolutionizing operations and driving success across various sectors.

- Enhance Precision and Efficiency with Digital Measuring Systems

- The Advantages of Automation in Measurement Processes

- Transforming Industries: Applications of Digital Measuring Technology

Enhance Precision and Efficiency with Digital Measuring Systems

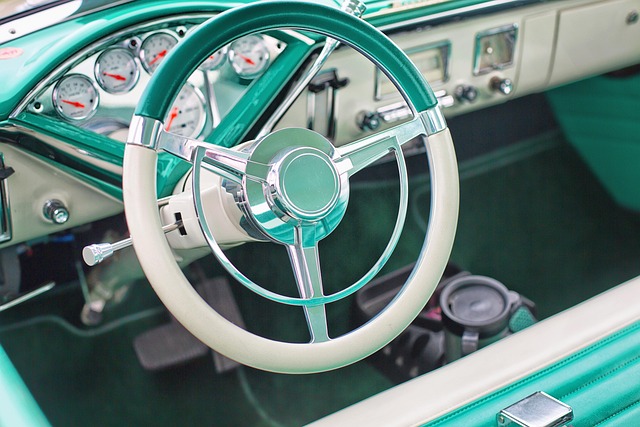

Digital measuring systems have revolutionized various industries, offering unprecedented precision and efficiency gains. In the realm of automotive restoration and collision repair, such systems play a pivotal role in ensuring meticulous work. For instance, in a Mercedes-Benz collision repair scenario, digital tools enable technicians to accurately measure and assess damage, facilitating precise repairs and restoring vehicles to their pre-accident condition with remarkable accuracy.

These systems streamline workflows by providing real-time data, reducing manual error, and enabling faster turnaround times. In the context of vehicle dent repair, for example, digital measuring tools can quickly capture and analyze surface imperfections, guiding technicians in performing spotless repairs that match the original finish perfectly. The advantages are clear: enhanced productivity, improved quality, and cost savings for both businesses and their clients.

The Advantages of Automation in Measurement Processes

In today’s fast-paced automotive industry, digital measuring systems offer a game-changer for car repair shops and bodyshops, revolutionizing measurement processes. Automation in this context brings numerous advantages, ensuring precision, speed, and efficiency. By implementing these systems, professionals can bid farewell to manual, time-consuming tasks that are prone to human error.

Digital measuring tools provide an accurate, real-time analysis of car body damage, especially in complex cases like fender repair or intricate car body restoration. This technology enables mechanics to quickly assess the extent of the issue, streamlining the entire repair process. Moreover, automation reduces the risk of errors during measurements, ensuring that each fix is precise and aligned with industry standards, ultimately leading to higher-quality car repairs.

Transforming Industries: Applications of Digital Measuring Technology

Digital measuring systems are revolutionizing various industries, bringing about significant transformations that enhance efficiency and accuracy. One notable area is auto body repair and collision damage restoration. Traditional methods often relied on manual measurements and subjective assessments, leading to inconsistencies. However, digital measuring technology offers a game-changer in this sector. These systems provide precise 3D scans and data, allowing for detailed analysis of vehicle damage, such as car dents or crash-related deformities.

By employing digital measuring systems, auto body repair shops can streamline their processes. Technicians can quickly capture accurate images, which are then analyzed to determine the extent of repairs needed. This not only saves time but also ensures consistent and high-quality outcomes in auto body repair, collision damage restoration, and car dent removal processes. The technology enables professionals to make informed decisions, leading to better customer satisfaction and increased trust in the industry.

Digital measuring systems are not just a trend, but an essential game-changer across industries. By enhancing precision and efficiency through automation, these systems offer numerous advantages that traditional methods can’t match. From manufacturing to healthcare, their applications are vast and transformative. Investing in digital measuring technology is no longer an option—it’s a strategic necessity for staying competitive and ensuring superior quality in today’s fast-paced world.