Automotive workshops face repair scheduling collisions when high demand overlaps, causing delays and disrupting operations. To mitigate this, they employ strategic techniques like advanced scheduling systems and cloud-based software for real-time data sharing. Efficient collision management optimizes resource allocation, reduces vehicle turnaround times, enhances operational efficiency, and improves customer satisfaction. Specialized centers prioritize tasks based on urgency and complexity to balance capacity, ensuring swift and cost-effective repair scheduling collision solutions.

In the dynamic landscape of maintenance management, understanding and mitigating repair scheduling collisions is paramount. This article delves into the intricacies of these common challenges, offering insights on efficient resource allocation strategies for seamless operations. We explore methods to optimize scheduling, minimizing disruptions and costs. By employing strategic approaches, organizations can enhance service delivery, improve customer satisfaction, and ensure optimal utilization of resources in the face of repair scheduling collisions.

- Understanding Common Repair Scheduling Collisions

- Efficient Resource Allocation Strategies for Smooth Operations

- Optimizing Scheduling to Minimize Disruptions and Costs

Understanding Common Repair Scheduling Collisions

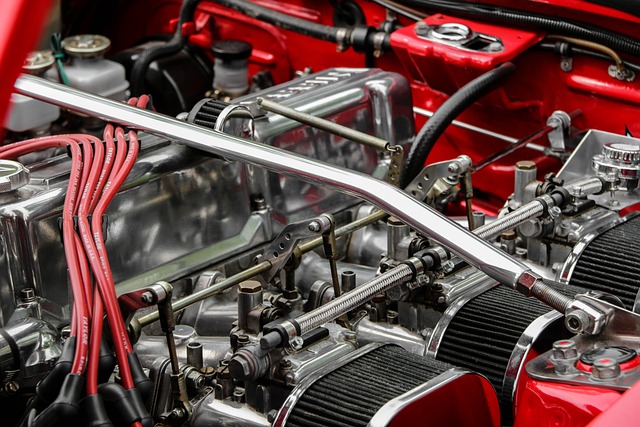

In the realm of automotive maintenance, understanding and effectively managing repair scheduling collisions is a complex yet pivotal task. These collisions occur when multiple vehicles require automotive body work or luxury vehicle repair simultaneously, leading to potential delays and resource bottlenecks in workshops. With a surge in car ownership and increasing demand for specialized car body repair services, collision management has become a critical aspect of ensuring customer satisfaction and efficient workshop operations.

The challenge arises from the fact that many workshops have limited slots and skilled technicians, making it difficult to accommodate all repairs at once. For instance, when a busy day coincides with several cars needing extensive car body repair, scheduling conflicts arise. This can result in longer wait times for customers and even lead to cancellations or rescheduling. Therefore, workshops must employ strategic collision mitigation techniques to streamline operations, optimize resource allocation, and maintain high service standards.

Efficient Resource Allocation Strategies for Smooth Operations

Efficient Resource allocation plays a pivotal role in minimising repair scheduling collisions and ensuring smooth operations for any automotive service centre. By optimising workforce distribution, tools, and materials, centres can streamline their processes, reduce wait times, and boost client satisfaction. One strategic approach is to implement a sophisticated scheduling system that considers the interdependencies of various tasks involved in vehicle restoration, collision damage repairs, or autobody repairs. This system should enable technicians to work on multiple projects simultaneously while avoiding conflicts, thereby maximising productivity without creating bottlenecks.

Additionally, leveraging technology like cloud-based software platforms can facilitate real-time data sharing and communication among team members. This enhances coordination and enables proactive decision-making, ensuring resources are allocated based on the current workload’s demands rather than anticipated future needs. Such strategies not only enhance operational efficiency but also contribute to a faster turnaround time for vehicle repairs, fostering a reputation for quality service and customer satisfaction.

Optimizing Scheduling to Minimize Disruptions and Costs

In the realm of collision repair, efficient scheduling is key to minimizing disruptions and costs. By implementing sophisticated algorithms and leveraging advanced technologies, collision repair centers can optimize their operations. This involves balancing the influx of damaged vehicles with available resources—technicians, parts, and equipment—to ensure swift and cost-effective repairs.

Strategic planning includes managing repair scheduling collisions effectively, prioritizing tasks based on urgency and complexity, and assigning resources accordingly. For instance, a specialized Mercedes-Benz repair center might schedule high-priority jobs during peak hours when more technicians are available, while less urgent but complex repairs can be scheduled for off-peak times to avoid bottlenecks. Such optimization ensures that customers experience minimal delays and that the collision repair center operates efficiently, maximizing productivity and profitability.

By efficiently managing repair scheduling collisions and optimizing resource allocation, organizations can significantly reduce disruptions and costs associated with maintenance operations. Understanding common challenges and implementing strategic solutions ensures a smoother, more cost-effective maintenance process. This, in turn, enhances overall operational efficiency and customer satisfaction.