Safety sensor recalibration demands meticulous preparation: acquiring diagnostic scanners, ensuring trained personnel, and understanding potential malfunctions. Accurate adjustments through targeted inspections, tests, and records enhance vehicle safety. Effective calibration techniques, crucial for real-world performance, prevent accidents in ADAS applications, facilitating safer driving environments.

Safety sensor recalibration is a critical process ensuring optimal performance of safety systems. This article guides you through essential steps, from preparing for recalibration by gathering necessary equipment and training personnel, to identifying sensor malfunctions and understanding failure modes. It delves into the core procedure of implementing calibration techniques, including adjusting and verifying sensitivity and accuracy. By following these key steps, you can ensure your safety sensors operate at peak efficiency, enhancing overall system reliability.

- Prepare for Recalibration: Gather Equipment and Train Personnel

- Identify Sensor Malfunctions and Understand Failure Modes

- Implement Calibration Techniques: Adjust and Verify Sensitivity and Accuracy

Prepare for Recalibration: Gather Equipment and Train Personnel

Before initiating the safety sensor recalibration process, it’s vital to prepare thoroughly. This involves gathering all necessary equipment and ensuring your team is adequately trained. Safety sensors, often integrated into modern vehicles’ airbag systems, require precise recalibration for optimal performance during collisions. Thus, you’ll need specialized tools designed for this delicate task, such as diagnostic scanners capable of interfacing with the vehicle’s computer system. These instruments facilitate accurate adjustments to sensor readings, ensuring they correspond to the specific make and model of the car body repair or auto glass replacement being undertaken.

Training is another critical component of preparation. Your personnel should be well-versed in the safety sensor recalibration process, understanding the intricacies involved in car body repair and vehicle body repair. This knowledge enables them to handle sensors with the utmost care, avoid damaging components, and interpret diagnostic data accurately. Proper training also enhances efficiency during the recalibration procedure, ensuring it’s executed correctly from the outset.

Identify Sensor Malfunctions and Understand Failure Modes

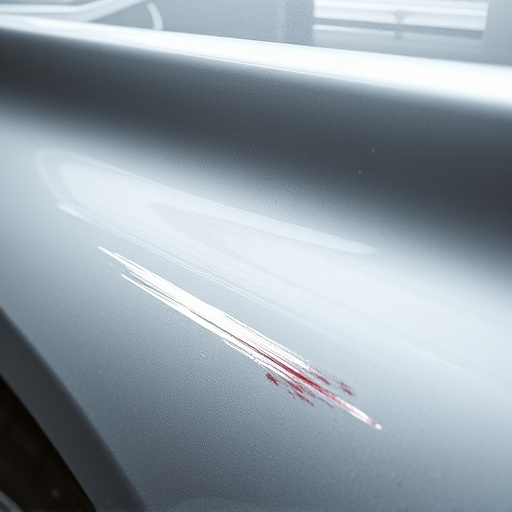

Before initiating the safety sensor recalibration process, it’s imperative to identify any sensor malfunctions and understand the potential failure modes. This step is crucial in ensuring accurate and reliable vehicle performance after recalibration. Safety sensors, such as those used in advanced driver-assistance systems (ADAS), are complex components that can fail due to various reasons, including physical damage, aging, or software glitches. For instance, a malfunctioning proximity sensor might not detect obstacles properly, leading to potential safety risks during auto glass replacement or hail damage repair processes.

Understanding failure modes helps mechanics pinpoint the root cause of sensor issues. This involves thorough inspections, diagnostic tests, and an analysis of past maintenance records. By identifying specific problems like sensor drift, signal interference, or hardware failures, technicians can perform targeted adjustments or replacements during the recalibration process, enhancing overall vehicle safety and the quality of subsequent car repair services.

Implement Calibration Techniques: Adjust and Verify Sensitivity and Accuracy

During the safety sensor recalibration process, implementing effective calibration techniques is paramount. This involves meticulously adjusting and verifying both the sensitivity and accuracy of the sensors. By fine-tuning these parameters, the system can detect even subtle changes in environmental conditions, ensuring optimal performance in real-world scenarios. For instance, in automotive applications, such as advanced driver-assistance systems (ADAS), precise recalibration is crucial for preventing accidents and facilitating seamless car collision repair processes.

Auto repair services that incorporate regular safety sensor recalibration benefit from enhanced reliability and reduced false alarms. This meticulous step not only improves the overall efficiency of bumper repair operations but also contributes to a safer driving environment. Through accurate sensitivity adjustments, sensors can more reliably trigger responses during emergencies, minimizing potential risks on the road.

The safety sensor recalibration process involves meticulous preparation, identification of malfunctions, and precise calibration techniques. By gathering the right equipment, training personnel, understanding failure modes, and adjusting sensitivity and accuracy, organizations can ensure their safety sensors operate at optimal levels. This proactive approach to safety sensor recalibration is a vital step in maintaining a secure and efficient environment, ultimately enhancing overall operational reliability.