Aluminum alloys with various elements offer unique advantages for automotive applications. Magnesium-based alloys enhance vehicle weight reduction and collision repair considerations. Visual inspection aids in identifying genuine aluminum body components through surface quality, detailing, and lack of corrosion. Testing methods like manufacturer's marks, serial numbers, and non-destructive testing ensure authenticity, crucial for maintaining vehicle aesthetics and longevity, especially in high-end models like Mercedes Benz.

Identifying genuine aluminum body components is crucial for ensuring vehicle quality and performance. This guide explores two essential aspects: understanding aluminum alloys and their unique properties, and mastering visual inspection techniques to detect authentic parts. Additionally, we delve into reliable testing methods for thorough authenticity verification. By equipping yourself with this knowledge, you’ll be able to easily discern high-quality aluminum body components in the automotive market.

- Understanding Aluminum Alloys and Their Properties

- Visual Inspection: Signs of Genuine Aluminum Components

- Testing Methods for Authenticity Verification

Understanding Aluminum Alloys and Their Properties

Aluminum is a versatile metal widely used in various industries, including automotive manufacturing. When it comes to identifying genuine aluminum body components, understanding the different alloys and their unique properties is essential. Aluminum alloys are classified based on their composition, with various elements like magnesium, copper, manganese, zinc, and silicon added to enhance specific characteristics. For instance, magnesium-based alloys are known for their excellent strength-to-weight ratio, making them ideal for automotive applications where reducing vehicle weight is a priority.

Each alloy has distinct mechanical properties that influence its suitability for different car parts. In the context of car collision repair and car paint services, knowing these properties can help professionals distinguish between genuine aluminum components and substitutes. For example, higher magnesium content in an alloy might offer better deformability during impact absorption, while specific silicon levels can affect the metal’s resistance to corrosion, a critical factor for maintaining the aesthetics and longevity of a vehicle’s exterior in a car repair shop.

Visual Inspection: Signs of Genuine Aluminum Components

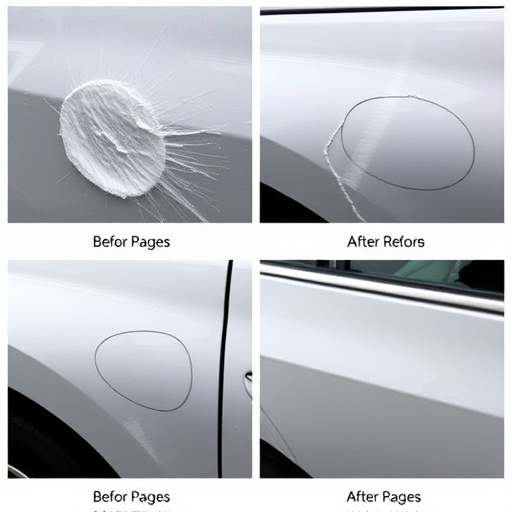

A quick visual inspection can often reveal genuine aluminum body components, especially on older vehicles. Look for a smooth, reflective surface with a metallic sheen—aluminum retains its luster and does not peel or chip easily. Check for any signs of oxidation; this appears as a dulling of the metal and may be accompanied by a powdery substance, which is a clear indicator that it’s aluminum. Genuine parts are also likely to have precise, clean lines and sharp edges, without any visible signs of rust or corrosion.

In contrast, if you notice imperfections like dents, scratches, or paint issues, especially in areas not typically exposed to the elements, it might suggest a component that has been repaired or replaced using less expensive materials. Compare with known genuine parts to get a clearer idea; experienced auto enthusiasts often use visual cues and knowledge of specific manufacturers’ practices to identify authentic aluminum body components, even without specialized tools. Remember, when in doubt, consult professionals like those found at reputable auto repair shops near you, who can offer expert advice and services, including paintless dent repair for minor damages.

Testing Methods for Authenticity Verification

To verify the authenticity of aluminum body components, several testing methods are available. One common approach is to check for the presence of a manufacturer’s mark or serial number, which can often be found stamped or etched onto the surface. This information is invaluable as it allows for quick cross-referencing with official records and ensures you’re acquiring genuine parts.

Additionally, utilizing specialized tools for non-destructive testing (NDT) can significantly aid in authentication. Techniques like fluorescent dye penetration testing and magnetic particle inspection are effective methods to detect any signs of structural damage or fabrication irregularities. For instance, a car scratch repair or vehicle restoration expert might employ these techniques when assessing aluminum body components, such as those found in a Mercedes Benz collision repair, to ensure they meet the required standards before integration into the vehicle.

Identifying genuine aluminum body components is crucial for ensuring vehicle quality and performance. By understanding different aluminum alloys and their unique properties, conducting visual inspections for distinct signs, and employing testing methods like chemical analysis or non-destructive testing, you can easily verify the authenticity of these components. Knowing how to discern real aluminum parts from substitutes is essential for both automotive professionals and enthusiasts, as it enables them to make informed decisions, maintain vehicle integrity, and drive with confidence.