Recycled collision parts offer an eco-friendly, cost-effective solution for automotive repairs and restorations, promoting a circular economy. Before installation, proper preparation is crucial, involving gathering tools, donning protective gear, and organizing parts. The meticulous installation process includes thorough vehicle inspection, surface preparation, securing frames, and using structural adhesives. Skilled technicians seamlessly integrate new parts for top-notch collision damage repair and enhanced aesthetics.

Looking to enhance your vehicle’s safety and sustainability? Discover the best practices for installing recycled collision parts. This comprehensive guide covers everything from understanding the benefits and types of recycled collision parts to preparing with essential tools and safety measures. We’ll walk you through a step-by-step installation process, complete with valuable tips to ensure a smooth, efficient, and secure fit.

- Understanding Recycled Collision Parts: Benefits and Types

- Preparation: Essential Tools and Safety Measures

- Installation Process: Step-by-Step Guide and Tips

Understanding Recycled Collision Parts: Benefits and Types

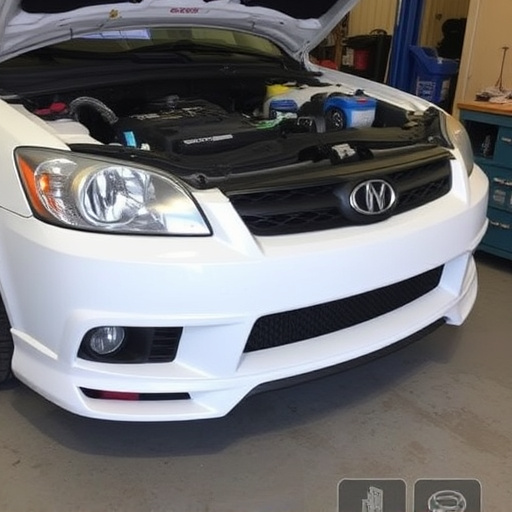

Recycled collision parts offer a sustainable solution for automotive repairs and restorations, providing numerous benefits to both repair shops and vehicle owners. These parts are sourced from damaged or wrecked vehicles that have been salvaged, with the aim of reusing and recycling materials instead of contributing to landfilling. This eco-friendly approach not only reduces environmental impact but also makes quality auto parts more accessible and affordable.

There are various types of recycled collision parts available, each catering to different needs in automotive restoration processes. Common categories include frame straightening components, which help restore the structural integrity of a vehicle after an accident. For enthusiasts engaged in classic car restoration, these parts offer a cost-effective alternative to original equipment manufacturer (OEM) pieces, allowing them to bring their vintage vehicles back to life while minimizing waste. Additionally, recycled collision parts can be utilized in car body restoration projects, contributing to the overall longevity of vehicles and promoting a circular economy.

Preparation: Essential Tools and Safety Measures

Before diving into the installation process, proper preparation is key when working with recycled collision parts. Gather all necessary tools and ensure a safe workspace. This includes protective gear like gloves and safety glasses to prevent any accidental exposure to debris or sharp edges. A well-lit area with ample space for maneuvering is ideal, especially as you handle smaller components. Having the right tools on hand is crucial; basic hand tools, specialized wrenches and sockets tailored to your vehicle’s make and model, and a variety of screwdrivers are essential. For more intricate tasks, consider an impact driver or air compressor.

Additionally, create a clean, organized layout of the parts on a workbench or floor, especially for complex repairs like car scratch repair or vehicle restoration. This visual organization streamlines the installation process, making it easier to locate and manage each component. Remember that efficient vehicle repair services rely on preparation, ensuring every tool and safety measure is in place before beginning any work.

Installation Process: Step-by-Step Guide and Tips

The installation process for recycled collision parts involves a meticulous approach to ensure both quality and safety. Begin by thoroughly inspecting the vehicle to identify the exact locations where the recycled parts will be fitted. This step is crucial in aligning the parts perfectly, matching the original manufacturer’s specifications. Next, prepare the surface by cleaning and decontaminating it to remove any dirt or debris. This ensures a clean bond between the old and new components.

When ready, start with the frame, securing the recycled collision parts using industry-standard fasteners. Ensure all bolts and brackets are tight and properly torqued for stability. For auto body services involving panels, use specialized adhesives designed for structural integrity. Allow adequate drying time as per the product instructions. This process requires precision and attention to detail; a skilled technician can then seamlessly integrate the new parts with the existing vehicle structure, offering top-notch collision damage repair and enhancing the overall aesthetics of the vehicle through efficient body shop services.

When properly installed, recycled collision parts offer a sustainable and cost-effective solution for vehicle repairs. By following best practices outlined in this guide, including understanding part types, preparing with essential tools and safety measures, and meticulously executing the installation process, you can ensure superior performance and contribute to a greener automotive industry. Incorporating recycled collision parts into your workflow is not just beneficial for the environment but also a smart choice for your bottom line.