Panel alignment procedures in hybrid and electric vehicles (HEVs) are crucial for maintaining structural integrity, safety, and aesthetic appeal. Skilled technicians use specialized equipment like laser systems to precisely measure and adjust panel gaps, ensuring factory specifications. This meticulous process involves aligning doors, fenders, hoods, and trunk lids, with car paint services to match original finishes, highlighting the precision required in HEV repairs.

In the realm of hybrid and electric vehicle (EV) repairs, proper panel alignment is paramount for ensuring structural integrity and aesthetic precision. This comprehensive guide delves into the intricate processes behind panel alignment procedures, equipping technicians with the knowledge to navigate the unique challenges posed by these modern vehicles. From understanding the fundamental principles of panel alignment in EVs to exploring specialized tools and providing a detailed step-by-step repair process, this article offers an indispensable resource for achieving seamless results in hybrid and electric vehicle service centers.

- Understanding Panel Alignment in Hybrid/Electric Vehicles

- Tools and Equipment for Precise Alignment

- Step-by-Step Guide to Effective Panel Repair and Alignment

Understanding Panel Alignment in Hybrid/Electric Vehicles

Panel alignment is a critical procedure in hybrid and electric vehicle (HEV) repairs, ensuring the precise fitting and positioning of exterior panels for optimal structural integrity and aesthetic appeal. Unlike conventional vehicles, HEVs often feature advanced body designs with complex panel configurations due to their unique propulsion systems and battery packs. Proper alignment is essential to maintain the vehicle’s overall performance, safety standards, and sleek appearance.

In HEV repairs, especially after a collision or accident, skilled technicians employ specialized equipment to measure and adjust panel gaps, ensuring they meet factory specifications. This meticulous process involves aligning the panels around the car’s body, including the doors, fenders, hood, and trunk lid. Car paint services may also be required post-alignment to match the vehicle’s original finish, adding an extra layer of precision and care in automotive repair.

Tools and Equipment for Precise Alignment

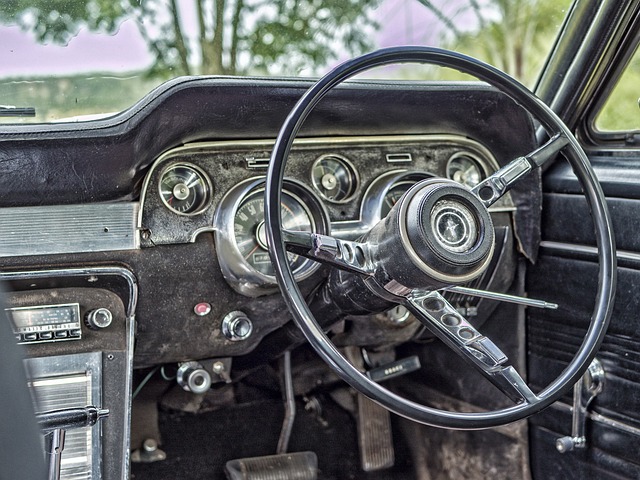

In the realm of hybrid and electric vehicle repairs, achieving precise panel alignment is paramount to ensuring structural integrity and aesthetic excellence. Automotive repair technicians rely on a suite of specialized tools and equipment designed to meet the unique requirements of these modern vehicles. Among these, laser alignment systems stand out for their accuracy and efficiency. These advanced tools project precise measurements and guide technicians through the intricate process, minimizing human error.

Additionally, high-quality dent repair tools play a crucial role in panel alignment procedures. From specialized pry bars to precision mallets, these instruments enable meticulous adjustments while preserving the vehicle’s original finish. A well-equipped vehicle body shop should incorporate such tools into their automotive repair services to deliver top-notch results for every customer, regardless of the complexity of the dent repair or panel replacement task at hand.

Step-by-Step Guide to Effective Panel Repair and Alignment

Repairing and aligning panels on hybrid or electric vehicles requires a meticulous approach to ensure structural integrity and aesthetic precision. Here’s a step-by-step guide for effective panel repair and alignment:

1. Safety First: Begin by securing the vehicle safely on a lift or jack stands, ensuring stability throughout the process. Protect yourself with safety gear, as working with precision tools demands caution. Next, carefully inspect the damaged panel, identifying the extent of the issue, whether it’s dented, cracked, or misaligned.

2. Demounting and Assessment: Demount the affected panel, taking note of its original position and any connected components. This step allows for a thorough analysis of the damage. Using specialized tools designed for panel alignment procedures, assess the frame’s condition and identify any discrepancies in panel placement.

3. Frame Straightening: If necessary, employ frame straightening techniques to return the vehicle’s undercarriage to its original specifications. This process ensures that all panels are aligned correctly with the vehicle’s overall structure.

4. Repair and Replacement: Based on your assessment, either repair the existing panel or replace it entirely. Utilize high-quality materials designed for hybrid and electric vehicles to maintain structural integrity and performance. While repairing, ensure all components are securely fastened and aligned accurately.

5. Reassembly and Alignment: After the panel is repaired or replaced, carefully reassemble the component, ensuring proper fitment. Use alignment tools to adjust the panel’s position, verifying its symmetry with surrounding panels. This meticulous process guarantees a seamless finish.

6. Quality Control: Conduct a final inspection, checking for any visible gaps, misalignments, or imperfections. Compare against manufacturer specifications and ensure all repairs meet auto repair services standards. A collision center equipped with advanced technology aids in achieving precise panel alignment.

Panel alignment is a critical process in hybrid and electric vehicle repairs, ensuring optimal performance and safety. By understanding the unique considerations of these vehicles and utilizing specialized tools, technicians can efficiently perform panel alignment procedures. The step-by-step guide provided offers a comprehensive framework for achieving precise results, contributing to the overall quality and reliability of the repair work.