Advanced adhesive applications transform industries like automotive, aerospace, and construction with high-strength, flexible, temperature-resistant bonds. Materials science enables precise paintless dent repairs and seamless integration with vintage materials for car restoration. These adhesives revolutionize auto body repair, enhancing structural integrity and speed while offering superior water resistance and long-term performance.

“Dive into the captivating world of advanced adhesive applications, where science meets innovation. This comprehensive guide unravels the key concepts and materials driving modern adhesion technology. From understanding specialized formulations tailored for unique industry needs to exploring practical implementation techniques, we demystify this field’s potential. Discover how advanced adhesives revolutionize diverse sectors, enhancing performance and efficiency. By the end, you’ll grasp the transformative power of these game-changing materials.”

- Unlocking Potential: Key Concepts of Advanced Adhesives

- Materials and Formulations for Specialized Applications

- Practical Implementation: Techniques and Industry Uses

Unlocking Potential: Key Concepts of Advanced Adhesives

In the realm of advanced adhesive applications, understanding key concepts is akin to unlocking a powerful toolset for professionals across diverse industries. These innovative adhesives offer more than just bonding—they revolutionize car body repair and vehicle restoration processes, ensuring structural integrity and aesthetic perfection. By leveraging cutting-edge formulations, manufacturers have developed adhesives capable of handling complex tasks, from precision scratch repairs to intricate assembly processes.

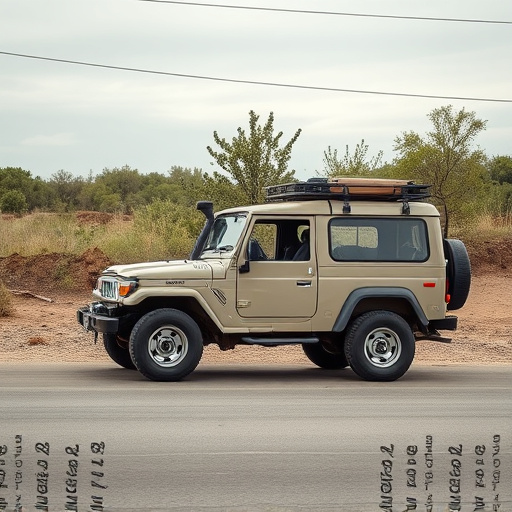

Advanced adhesive applications transcend basic adhesion, incorporating properties like high tensile strength, flexibility, and resistance to extreme temperatures. This versatility enables their use in demanding sectors such as automotive, aerospace, and construction. In the context of car body repair and vehicle restoration, these adhesives play a pivotal role in ensuring long-lasting repairs that rival the original manufacturing quality. Their precision and efficiency not only save time but also contribute to more sustainable practices by minimizing material waste.

Materials and Formulations for Specialized Applications

In the realm of advanced adhesive applications, materials and formulations play a pivotal role in achieving specialized tasks across various industries. Adhesives used for paintless dent repair, for instance, require unique properties to match the flexibility and finish of automotive paintwork. This demands a blend of precise polymer chemistry and innovative reinforcing agents that can restore cars’ original appearances without leaving traces of damage or visible evidence of repair in the automotive repair process.

For car restoration projects, advanced adhesives must withstand harsh environmental conditions while ensuring longevity and compatibility with vintage materials. Formulations are tailored to mimic historical adhesive recipes where available, respecting the authenticity of restored vehicles. Modern advancements leverage specialized elastomers, resins, and crosslinkers to deliver exceptional bond strength, flexibility, and durability—essential characteristics for intricate advanced adhesive applications across automotive, aerospace, and even marine restoration sectors.

Practical Implementation: Techniques and Industry Uses

The practical implementation of advanced adhesive applications is a fascinating aspect that has transformed various industries, particularly in the automotive sector. Auto collision centers and vehicle body repair shops have embraced these techniques to achieve precise and durable results during auto body shop operations. Adhesives, once considered mere glue, have evolved into sophisticated materials capable of bonding diverse substrates, from metal and composites to glass and rubber. This evolution has led to innovative solutions in everything from structural repairs to intricate trim installations.

In the automotive realm, advanced adhesives play a critical role in modern vehicle design, enhancing safety and efficiency. They are utilized for adhering high-strength materials like carbon fiber composites, ensuring lightweight yet robust structures. Moreover, these adhesives excel in sealing applications, providing excellent water resistance and long-term performance, which is vital for maintaining the integrity of vehicles over time. This versatility has made them indispensable tools in auto body shops, enabling faster turnaround times and superior quality repairs.

Advanced adhesive applications have evolved to meet the demanding needs of modern industries, offering innovative solutions through specialized materials and cutting-edge techniques. By understanding the key concepts, exploring diverse formulations, and adopting practical implementation strategies, professionals can unlock unprecedented bonding possibilities. These advanced adhesives are transforming various sectors, ensuring stronger, more durable connections in everything from manufacturing to healthcare. Embracing these developments enables businesses to stay ahead in a rapidly evolving landscape, where the potential of advanced adhesive applications continues to be embraced and explored.