Spot weld bonding repairs are crucial for maintaining commercial fleet vehicles' integrity and safety. Skilled technicians assess damage, remove affected welds, and apply new ones adhering to industry standards. Quality control involves thorough inspections and testing to ensure structural integrity after auto glass replacement or minor collisions. Best practices include proper preparation, clean surfaces, specialized tools, and advanced technologies like digital measurement tools for precise alignment and bond strength.

In the manufacturing industry, ensuring robust and reliable bonds is paramount, especially through spot weld bonding repairs. This article delves into the intricacies of achieving superior repair quality, focusing on industry standards and best practices. We’ll explore the fundamentals of spot weld bonding repairs, understand key assessment metrics, and uncover effective techniques. By adhering to established standards, manufacturers can maintain structural integrity, minimize defects, and optimize productivity in their welding processes.

- Understanding Spot Weld Bonding Repair Basics

- Industry Standards and Quality Assessment

- Best Practices for Effective Repair Techniques

Understanding Spot Weld Bonding Repair Basics

Spot weld bonding repairs are a critical aspect of maintaining vehicle integrity and safety, particularly for commercial fleets. These repairs involve the precise re-welding of metal components to restore structural strength and prevent further damage. Understanding the basics is essential for fleet repair services as it ensures consistent quality control in automotive restoration processes.

The process starts with identifying the extent of the damage, which could range from small cracks to significant structural breaches. Skilled technicians then carefully remove the affected spot welds, often utilizing specialized equipment to achieve clean and precise cuts. Once the damaged area is prepared, new welds are applied, following strict industry standards for optimal bond strength and durability. This meticulous approach is crucial in ensuring the longevity of auto glass repair and overall vehicle performance.

Industry Standards and Quality Assessment

In the realm of spot weld bonding repairs, industry standards serve as a beacon guiding professionals to ensure optimal quality and safety in vehicle body repair. These standards are meticulously crafted to address various aspects, from material selection to application techniques, to guarantee robust and long-lasting repairs, particularly for auto glass replacement or fender bender scenarios. Quality assessment plays a pivotal role here, involving meticulous inspections and rigorous testing to verify the integrity of each spot weld bonding repair.

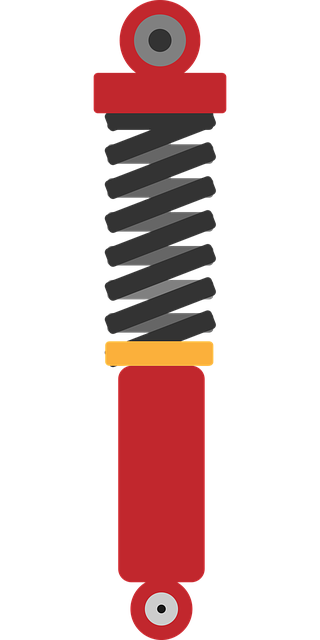

Professionals in this domain must adhere to these standards, employing advanced tools and techniques to gauge the strength and durability of the bonds. This meticulous process involves evaluating factors like bond alignment, material compatibility, and the absence of defects or residual stress, all of which are crucial determinants for a successful spot weld bonding repair that surpasses mere aesthetics, ensuring the structural soundness of vehicles, even after seemingly minor incidents like fender benders.

Best Practices for Effective Repair Techniques

To achieve optimal results in spot weld bonding repair, adherence to best practices is paramount. These include meticulous preparation of the damaged area, ensuring surfaces are clean and free from debris. Using the right tools and equipment, such as specialized bonders and applicators, can significantly enhance precision and quality. Proper training for technicians on the latest repair techniques and materials ensures consistency and effectiveness.

In a collision center or classic car restoration shop, where fender benders are common, having robust standards for spot weld bonding repair is crucial. This involves not just repairing the visible damage but also ensuring structural integrity, which is vital for safety and longevity of the vehicle. Employing advanced technologies like digital measurement tools can help in achieving precise alignment and bond strength, making repairs as good as new.

Spot weld bonding repair is a critical process that demands adherence to industry standards to ensure structural integrity and product quality. By understanding the basics, employing effective best practices, and leveraging established assessment methods, professionals can consistently deliver high-quality repairs. This ensures that products meet safety requirements and maintain their intended performance, fostering customer confidence in manufacturing excellence.