The evolution of auto body panel replacement tools has mirrored advancements in the automotive industry, transitioning from manual labor to sophisticated technology. Innovations like computer-aided design (CAD) and robotic welding systems have dramatically improved precision, efficiency, and safety in repair processes. These developments, driven by lighter vehicle designs and safety standards, enable collision repair centers to deliver superior quality repairs with reduced downtime for vehicle owners.

In the dynamic landscape of automotive repair, auto body panel replacement has evolved significantly. This article delves into the tools that drive modern auto body panel replacement, tracing the evolution from traditional to innovative solutions. From hammers and saws to state-of-the-art robotics and AI, we explore how technology is transforming this crucial aspect of vehicle restoration. Discover the essential tools and equipment that streamline efficiency, accuracy, and safety in today’s high-precision auto body panel replacement work.

- The Evolution of Tools for Auto Body Panel Replacement

- – A historical overview of tools used in auto body repair

- – Transition from traditional to modern tools

The Evolution of Tools for Auto Body Panel Replacement

The evolution of tools for auto body panel replacement has mirrored the broader advancements in the automotive industry. Historically reliant on manual labor and rudimentary instruments, modern auto body repair now leverages a sophisticated array of equipment designed to enhance precision, efficiency, and safety. The shift towards computer-aided design (CAD) and advanced materials has necessitated corresponding tool innovations.

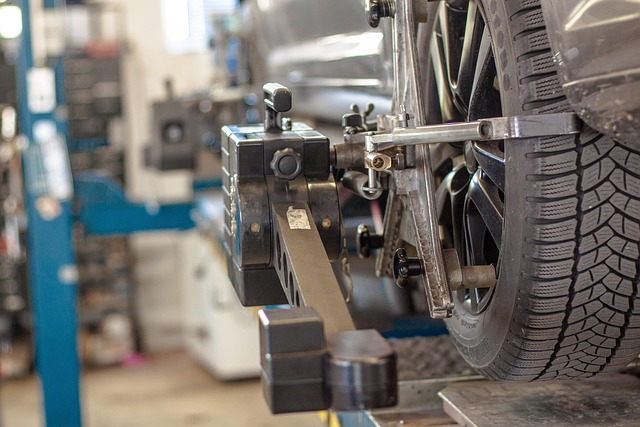

Today’s professional auto maintenance workshops are equipped with robotic welding systems that ensure consistent, high-quality joint formations. Additionally, specialized tools like vacuum bagging systems for degassing and curing car paint services have revolutionized the process, making it faster and more reliable. These advancements not only streamline automotive repair but also contribute to the overall quality and longevity of vehicles, reflecting the ongoing pursuit of excellence in the field.

– A historical overview of tools used in auto body repair

The tools used in auto body panel replacement have evolved significantly over time, mirroring advancements in technology and safety standards. Historically, before the mid-20th century, auto body repair was largely a manual process involving hammers, chisels, and file tools. Technicians would meticulously reshape metal panels by hand, a laborious and time-consuming task that required immense skill. The advent of mass production in the automotive industry led to the introduction of more specialized tools, such as hydraulic presses and welding machines, streamlining the auto body repair process.

With the push for lighter and safer vehicles in recent decades, the focus has shifted towards precision and efficiency in auto body panel replacement. Modern tools like robotic welders, computer-aided design (CAD) software, and laser measuring devices have revolutionized car body repair. These innovations enable technicians to achieve seamless fits, reduce waste, and ensure structural integrity, ultimately improving the overall quality of auto frame repair and auto dent repair services.

– Transition from traditional to modern tools

The auto body panel replacement landscape has undergone a significant evolution, transitioning from traditional hand tools to modern, advanced equipment. This shift reflects the increasing complexity and precision required in the industry. Today’s auto body shops and collision repair centers are equipped with cutting-edge technologies designed to streamline the repair process, enhance accuracy, and reduce downtime for vehicle owners. For instance, robotic welding systems offer unparalleled consistency and speed, while computer-aided design (CAD) software enables technicians to plan and execute intricate panel replacements with ease.

This modern approach goes beyond simply fixing car scratches or minor dents; it involves a holistic improvement in the overall efficiency and quality of auto body work. With access to specialized tools tailored for different vehicle makes and models, collision repair professionals can now deliver more precise and structurally sound repairs, ensuring vehicles return to the road in top condition.

Modern auto body panel replacement work has undergone a significant transformation, driven by technological advancements. The evolution from traditional to modern tools has revolutionized the efficiency and precision of repairs, ensuring faster turnaround times and superior quality outcomes. These advanced tools not only simplify complex tasks but also enhance safety for both technicians and vehicles, making auto body panel replacement a more streamlined process in today’s automotive industry.