Panel alignment procedures are crucial for mobile collision repair, ensuring vehicle panels fit seamlessly after an accident. Skilled technicians use advanced tools like laser measuring and 3D scanning to meticulously realign damaged parts to factory specs, maintaining structural integrity and restoring vehicles to pre-accident condition. This process demands precision, utilizing tools such as laser alignment systems, torque wrenches, angle gauges, and straight edges. Efficient panel alignment guarantees high-quality fender repair for vehicles like Mercedes Benz.

In the fast-paced world of mobile collision repair, precise panel alignment is crucial for ensuring high-quality, industry-standard results. This comprehensive guide delves into the essential practices and techniques behind effective panel alignment procedures. From understanding the fundamentals to equipping yourself with the right tools, we provide a step-by-step approach designed to streamline your workflow. By mastering these methods, mobile repair services can deliver impeccable repairs, enhancing customer satisfaction and maintaining their reputation.

- Understanding Panel Alignment in Mobile Repair

- Essential Tools and Equipment for Precise Alignment

- Step-by-Step Guide to Efficient Panel Alignment Procedures

Understanding Panel Alignment in Mobile Repair

Panel alignment is a critical process in mobile collision repair, ensuring that vehicle panels fit seamlessly after an accident. It involves adjusting and realigning damaged body parts to their original factory specifications. This meticulous procedure is essential for achieving a precise, high-quality repair, maintaining the structural integrity of the vehicle, and restoring it to its pre-accident condition.

In an automotive body shop or collision repair shop, skilled technicians use specialized equipment and tools to perform panel alignment procedures. They carefully assess the damage, disassemble affected components if needed, and then employ techniques like laser measuring, 3D scanning, or manual adjustments to bring panels back into proper alignment. The goal is not just to fix visible imperfections but also to ensure the vehicle’s overall safety and performance are not compromised.

Essential Tools and Equipment for Precise Alignment

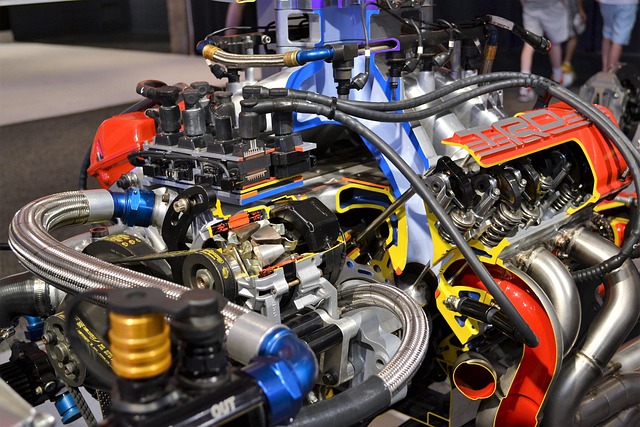

When it comes to panel alignment procedures for mobile collision repair services, having the right tools and equipment is paramount. To achieve precise results in auto repair services or vehicle restoration, professionals rely on a set of specialized instruments designed to accurately gauge and adjust panel positions. Among these essential tools are laser alignment systems, which offer unmatched accuracy and efficiency compared to traditional methods. These advanced systems project precise beams that help technicians realign components with millimetre precision.

Additionally, high-quality torques wrenches, angle gauges, and straight edges play crucial roles in the process. Torque wrenches ensure secure fastening of parts while maintaining proper torque specifications, preventing future misalignments. Angle gauges help measure angles with accuracy, critical for aligning suspension systems and frames. Straight edges, on the other hand, are indispensable for checking flatness and straightness, ensuring panels are restored to their original condition in vehicle restoration efforts.

Step-by-Step Guide to Efficient Panel Alignment Procedures

Efficient panel alignment is a critical step in mobile collision repair services, ensuring precision and quality workmanship. Here’s a step-by-step guide for achieving accurate results:

1. Inspection: Begin by thoroughly inspecting the damaged area. Identify the extent of the damage, including any deformations or misalignments in the vehicle’s bodywork, focusing specifically on fender repair. Take detailed notes to guide your alignment process.

2. Tool Preparation: Gather all necessary tools for panel alignment. This includes specialized alignment equipment and hand tools designed for precise adjustments. For Mercedes Benz repair or any high-end vehicle, consider using advanced alignment systems that offer greater accuracy and precision.

3. Loosening and Adjusting: Start loosening the affected panels using the appropriate tools while keeping the surrounding areas secure. Make incremental adjustments to realign the panel with the vehicle’s frame. Ensure each adjustment is precise, especially in complex vehicle bodywork.

4. Re-fastening: Once satisfied with the alignment, re-fasten the panels securely. This step ensures the structural integrity of the repair, maintaining the overall quality of the vehicle’s appearance and performance.

5. Final Verification: Conduct a final inspection to verify the panel alignment. Check for any gaps or misalignments that may have been missed. Using advanced measurement tools can help capture even the slightest imperfections, ensuring your fender repair meets the highest standards.

Panel alignment procedures are a cornerstone of efficient mobile collision repair services, ensuring vehicles return to their pre-accident condition. By understanding the process, investing in the right tools, and following a structured guide, mobile repair technicians can deliver high-quality work that satisfies both customers and insurance providers. Implementing these panel alignment best practices is key to staying competitive in the digital era, where customer expectations and service quality are paramount.