Carbon fiber repair methods have revolutionized automotive manufacturing, offering lightweight, strong materials that enhance performance and fuel efficiency while preserving aesthetics. Historically time-consuming and visually distinctive, these repairs now employ advanced techniques like fiber placement and automated laying, seamlessly integrating with vehicle construction. This evolution has raised quality standards in collision and paint repair, particularly for high-end vehicles, and transformed body shop capabilities. Future advancements promise greater efficiency, sustainability, and precision, benefiting not just autos but aerospace and other sectors reliant on carbon fiber composites. Auto detailing professionals must stay updated to provide specialized services for maintaining and repairing these innovative materials.

Carbon fiber repair methods have undergone a remarkable evolution, transforming the auto industry. Once considered niche, these techniques are now integral to manufacturing high-performance vehicles. This article explores the evolution of carbon fiber repair techniques from basic to advanced methodologies, delving into their advantages and disruptive impact on automotive manufacturing. We also look ahead to future prospects, predicting continued innovation in this game-changing field.

- Evolution of Carbon Fiber Repair Techniques: From Basic to Advanced

- Advantages and Disruptive Impact on Automotive Manufacturing

- Future Prospects: Continuing Innovation in Carbon Fiber Repairs

Evolution of Carbon Fiber Repair Techniques: From Basic to Advanced

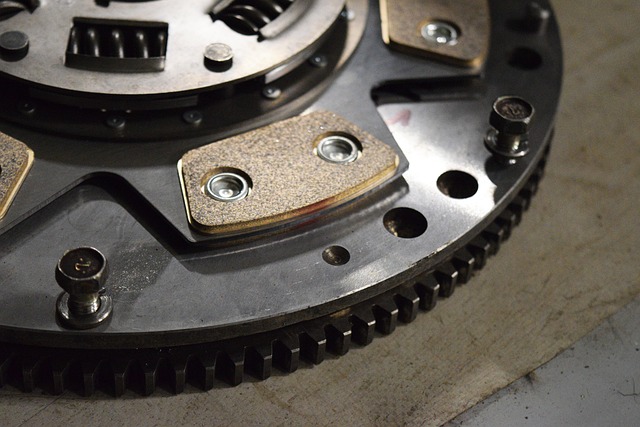

The evolution of carbon fiber repair techniques has revolutionized automotive manufacturing and restoration. Historically, repairs involved basic methods like drilling out damaged areas and replacing them with traditional composite materials. These processes were time-consuming and often resulted in visible repair lines, compromising the structural integrity and aesthetic appeal of high-performance vehicles.

Over time, advancements in technology have led to more sophisticated carbon fiber repair methods. Today, auto body repair specialists employ advanced techniques such as fiber placement and automated laying, allowing for precise repairs that seamlessly integrate with the vehicle’s original construction. These innovations not only enhance structural strength but also ensure exquisite finish, making it nearly impossible to distinguish repaired areas from the pristine factory work. This shift has significantly elevated the standard of quality in automotive collision repair and vehicle paint repair, particularly for high-end sports cars and luxury vehicles where aesthetics and performance go hand in hand.

Advantages and Disruptive Impact on Automotive Manufacturing

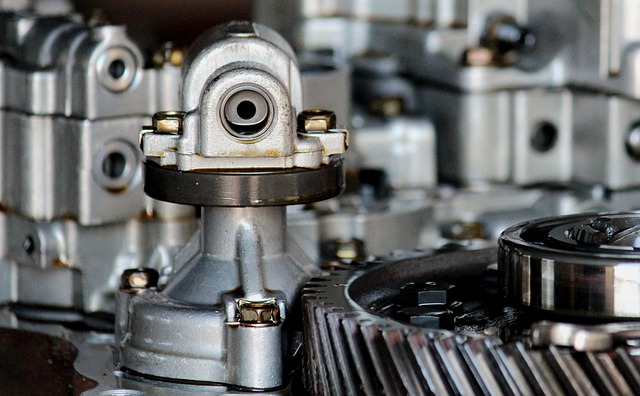

Carbon fiber repair methods have brought about a significant shift in the automotive manufacturing landscape, offering both advantages and disruptive impacts. One of the key benefits is their ability to provide lightweight yet incredibly strong materials, replacing traditional metal components in various vehicle parts. This not only enhances fuel efficiency but also improves overall vehicle performance. Carbon fiber repair techniques enable precise and intricate repairs, ensuring structural integrity without compromising aesthetics, a significant advantage over conventional car scratch repair or car collision repair methods.

In automotive body shops, the adoption of these repair methods has been transformative. It allows for more complex design elements to be incorporated into vehicles, pushing the boundaries of what’s possible in car design. Furthermore, carbon fiber repair offers cost-effective solutions for both minor and major damage, making it a versatile option. This disruptive technology is reshaping the industry, fostering innovation and setting new standards for automotive manufacturing and repair processes.

Future Prospects: Continuing Innovation in Carbon Fiber Repairs

The future of carbon fiber repair methods in the auto industry looks promising, with continuous innovation set to redefine standards once again. As technology advances, we can expect even more efficient and sustainable solutions for repairing this high-performance material. Researchers are exploring new techniques, such as advanced composite bonding agents and automated repair systems, which will make the process faster, more precise, and environmentally friendly. These advancements are not only relevant to the automotive sector but also have implications for aerospace and other industries that heavily rely on carbon fiber composites.

With growing demand for lightweight and durable materials in various sectors, carbon fiber repair methods will continue to evolve, ensuring longer-lasting vehicles and reducing waste. Auto detailing professionals can play a significant role in this process by staying updated with these innovations, enabling them to offer specialized services for maintaining and repairing carbon fiber components. This trend reinforces the importance of continuous learning and adaptation within the auto collision center industry, keeping up with the rapid changes that shape modern automotive care.

Carbon fiber repair methods have undergone a remarkable evolution, transforming the automotive industry with their advanced capabilities. As these techniques continue to innovate, they promise lighter, stronger, and more sustainable vehicles. The future of automotive manufacturing looks set to be defined by the seamless integration of carbon fiber repairs, pushing the boundaries of what’s possible in vehicle design and performance.