3D vehicle scanning has revolutionized the automotive industry by providing highly detailed digital models of vehicles, enhancing design, manufacturing, and repair processes. This technology allows for precise prototyping, accurate parts tracking, and flawless body repairs, significantly reducing errors and speeding up development cycles. It's particularly valuable in collision centers for achieving structural integrity and aesthetic appeal through meticulous frame straightening and paint repairs.

“Unleashing the potential of 3D vehicle scanning, this article delves into the transformative technology revolutionizing the automotive landscape. From design and manufacturing to safety and customization, 3D scanning offers unprecedented advantages. It enables accurate modeling and prototyping, enhancing creative iterations. In quality control, it ensures meticulous inspection, detecting even the subtlest flaws. Moreover, it facilitates restoration of historical vehicles while empowering personalized modifications. Embrace the future of motoring with 3D vehicle scanning.”

- Revolutionizing Vehicle Design and Manufacturing with 3D Scanning

- – The benefits of 3D scanning technology in the automotive industry

- – Accurate modeling and prototyping for improved design iterations

Revolutionizing Vehicle Design and Manufacturing with 3D Scanning

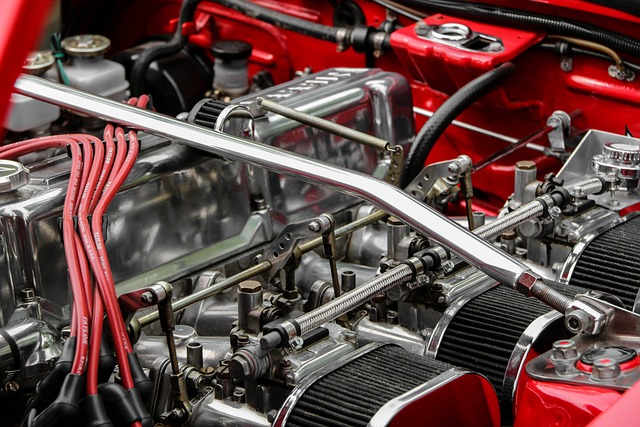

The advent of 3D vehicle scanning has revolutionized both vehicle design and manufacturing processes. This cutting-edge technology allows for precise digital replicas of cars, providing designers with an unparalleled level of detail and flexibility. With 3D scanning, every curve, contour, and feature of a vehicle can be captured and analyzed, enabling more accurate prototyping and design iterations.

In the car body shop, 3D scanning plays a pivotal role in enhancing efficiency and accuracy during repairs or restoration projects. It facilitates detailed inspection of vehicle bodywork, identifying damages or discrepancies down to the smallest fraction. This level of precision is crucial for achieving flawless outcomes in vehicle paint repair and overall bodywork restoration, ensuring each car returns to its optimal condition.

– The benefits of 3D scanning technology in the automotive industry

The automotive industry has witnessed a significant transformation with the advent of 3D scanning technology, revolutionizing various aspects of vehicle manufacturing and maintenance. This cutting-edge tool offers an array of benefits, ensuring enhanced precision and efficiency in every step of the process. One of its primary advantages is the ability to capture detailed 3D models of vehicles, providing a comprehensive digital representation. This is particularly useful for auto body repair and fender repair processes, where exact measurements are crucial. With 3D scanning, technicians can quickly and accurately identify damage, ensuring that every dent or scratch is accounted for during repairs, resulting in superior quality outcomes.

Moreover, the technology streamlines the design and manufacturing stages. It enables engineers to create precise digital prototypes, facilitating faster development cycles and easier modifications. This is especially valuable for complex vehicle components, where traditional measuring methods might prove time-consuming and error-prone. Additionally, 3D scanning aids in inventory management, allowing businesses to track parts more efficiently and reduce the likelihood of human errors during ordering and fitting, which is a significant advantage when considering the intricate nature of modern vehicles and the need for precise auto body repair.

– Accurate modeling and prototyping for improved design iterations

In the realm of automotive development, 3D vehicle scanning has emerged as a game-changer, enabling precise modeling and prototyping. This cutting-edge technology captures intricate vehicle details with remarkable accuracy, fostering improved design iterations. By digitizing vehicle components down to the smallest angle and curve, engineers gain access to detailed 3D models that serve as reliable blueprints for manufacturing and testing. This process significantly reduces errors associated with traditional manual measurements, resulting in more efficient and cost-effective development cycles.

Furthermore, accurate 3D scanning enhances precision in various automotive services, such as frame straightening and collision center operations. It aids technicians in accurately assessing damage, ensuring that every curve and contour of the vehicle is considered during repair or restoration processes, including meticulous vehicle paint repair work. This level of detail-oriented precision not only preserves the aesthetic appeal but also ensures structural integrity, making 3D vehicle scanning an indispensable tool in modern automotive care.

3D vehicle scanning is transforming the automotive landscape by offering unparalleled accuracy and efficiency. By leveraging this technology, manufacturers can streamline design and manufacturing processes, leading to faster development cycles and improved product quality. The benefits of 3D scanning, such as accurate modeling and prototyping, enable designers and engineers to make informed decisions, enhancing overall innovation in the industry. Embracing 3D vehicle scanning represents a significant step towards a future of smarter, more efficient vehicles.