Repair Quality Verification (RQV) is a critical process ensuring vehicle repairs meet high standards through systematic inspections and advanced tools. Today, digital techniques leverage algorithms and imaging to detect subtle issues in collision, bumper, and dent repairs, enhancing safety and confidence. Best practices for RQV involve tailored protocols, advanced diagnostic tools, regular training, clear communication, detailed records, and feedback mechanisms, ensuring precise and reliable repair processes.

In today’s digital age, ensuring the integrity of repairs is paramount. Repair Quality Verification (VQ) plays a pivotal role in detecting hidden issues that might go unnoticed. This article delves into the intricate process of VQ, highlighting its ability to unveil concealed problems through advanced techniques. We explore best practices to guarantee accuracy in repair quality verification, emphasizing its significance in maintaining high-quality standards and fostering customer trust. Understanding these methods is crucial for anyone aiming to enhance post-repair outcomes.

- Understanding Repair Quality Verification Process

- Unveiling Hidden Repair Issues with Advanced Techniques

- Ensuring Accuracy: Best Practices for Effective VQ

Understanding Repair Quality Verification Process

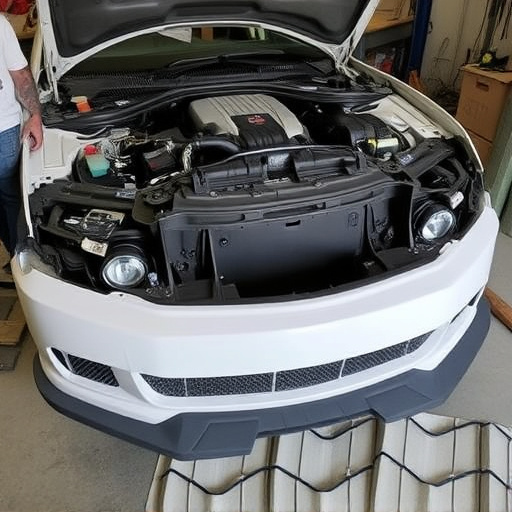

The Repair Quality Verification (RQV) process is a meticulous and crucial step in ensuring that vehicle repairs are executed to the highest standards. It involves a systematic inspection of the repaired vehicle, focusing on both structural integrity and aesthetic precision. This verification goes beyond visual assessment; it includes functional tests and quality checks using specialized tools and techniques. The goal is to uncover any hidden defects or inconsistencies that might have escaped initial repair work, especially in intricate areas like car body restoration and vehicle paint repair.

RVQ meticulously scrutinizes every aspect of the repair, from alignment and panel gaps to paint clarity and color match. By employing advanced detection methods, it can identify subtle issues such as misaligned panels, improper body gaps, or uneven paint application. This process not only guarantees that cars undergo comprehensive quality checks but also reassures owners that their vehicles are safe and reliable on the road.

Unveiling Hidden Repair Issues with Advanced Techniques

In today’s digital era, advanced techniques like repair quality verification play a pivotal role in unveiling hidden repair issues that might go unnoticed during traditional assessment methods. These sophisticated tools employ intricate algorithms and high-resolution imaging to scrutinize every detail of automotive collision repair, bumper repair, or vehicle dent repair processes. By analyzing data from various sensors and cameras, they can detect even the slightest discrepancies or abnormalities not readily apparent to the human eye.

Through this enhanced verification process, professionals gain invaluable insights into potential weaknesses or errors that may compromise the structural integrity and overall quality of the repairs. This proactive approach ensures that vehicles leave the workshop with meticulous craftsmanship, adhering to stringent safety standards, thus instilling confidence in both repair technicians and vehicle owners alike.

Ensuring Accuracy: Best Practices for Effective VQ

Ensuring Accuracy: Best Practices for Effective VQ

The effectiveness of Repair Quality Verification (VQ) lies in its ability to unearth hidden repair issues that might go unnoticed during initial inspections. To maximize the accuracy of VQ, auto repair shops should adhere to stringent best practices. This includes employing meticulous inspection protocols tailored to different vehicle makes and models, utilizing advanced diagnostic tools to detect even subtle anomalies, and ensuring a comprehensive review of both structural and cosmetic aspects of autobody repairs. Regular training sessions for technicians on the latest repair techniques and quality control measures are also paramount in maintaining high standards.

Additionally, clear communication between technicians, inspectors, and clients is crucial. Detailed records of every repair step, including parts used and labor performed, create a transparent audit trail that enhances accountability. Continuous evaluation of VQ processes through feedback mechanisms allows for identifying areas of improvement, thereby refining the overall quality of car bodywork services provided. By integrating these best practices, auto repair shops can confidently ensure the precision and reliability of their repair quality verification processes.

Repair Quality Verification (VQ) plays a pivotal role in ensuring that repairs are not just visible but also hidden issues are accurately detected. By employing advanced techniques, professionals can unearth potential problems that might otherwise go unnoticed. Adhering to best practices for VQ is essential to maintaining high standards and preventing future complications. This comprehensive approach guarantees that every repair meets the required quality benchmarks, offering peace of mind to both repair providers and clients alike.