Computerized frame measurement tools revolutionize auto body repair and restoration, providing unparalleled precision and efficiency through detailed digital models. These systems detect even subtle deformities, ensuring meticulous repairs and accurate planning. In manufacturing and construction, real-time diagnostics powered by these tools instantly identify structural defects, reducing rework time, enhancing productivity, and minimizing costs. For auto shops, implementing computerized frame measurement systems transforms dent repair services, leading to consistent accuracy and enhanced customer satisfaction in a competitive market.

“Discover the transformative power of real-time diagnostics through advanced Computerized Frame Measurement tools. This article explores the evolution of manufacturing and construction with these innovative systems. From understanding the fundamentals of computerized frame measurement to unlocking significant benefits in process efficiency, accuracy, and productivity, we delve into successful implementation strategies. Learn how these tools optimize workflows, reduce errors, and drive informed decision-making for various industries.”

- Understanding Computerized Frame Measurement Tools

- Benefits of Real-Time Diagnostics in Manufacturing and Construction

- Implementing and Optimizing Computerized Frame Measurement Systems

Understanding Computerized Frame Measurement Tools

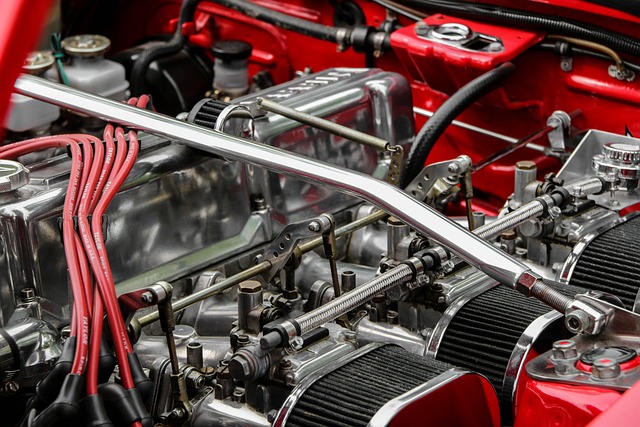

Computerized frame measurement tools have revolutionized the way professionals approach auto body repair and car restoration processes. These advanced systems utilize cutting-edge technology to accurately measure and analyze a vehicle’s structural integrity in real time, offering unprecedented precision and efficiency. By generating detailed digital models of the car body, these tools enable technicians to detect even the slightest deformities or discrepancies that might go unnoticed during manual inspections.

In the realm of car body restoration, these computerized measurement techniques play a pivotal role, ensuring every repair is executed with meticulous care. Auto body repair specialists can quickly assess damage, determine the extent of required repairs, and precisely plan their restoration efforts. This not only streamlines the entire process but also guarantees that each vehicle returns to its original specifications, enhancing safety and performance in the post-restoration phase.

Benefits of Real-Time Diagnostics in Manufacturing and Construction

In manufacturing and construction industries, real-time diagnostics powered by computerized frame measurement tools have revolutionized quality control processes. These advanced systems enable immediate detection of defects or deviations from specifications in structural frames, reducing the time spent on manual inspections and rework. This not only enhances overall productivity but also ensures higher precision and consistency in final products. For instance, in auto frame repair or car restoration services, real-time diagnostics can swiftly identify misalignments or damage, allowing technicians to address issues promptly, thus improving vehicle safety and customer satisfaction.

Moreover, the integration of computerized frame measurement into manufacturing pipelines facilitates predictive maintenance by monitoring frames’ health continuously. This proactive approach helps anticipate potential failures before they occur, minimizing downtime and maintenance costs. Such benefits are particularly valuable in construction projects, where structural integrity is paramount for worker safety and project timeline adherence.

Implementing and Optimizing Computerized Frame Measurement Systems

Implementing and optimizing computerized frame measurement systems is a critical step for any auto body shop aiming to enhance its car dent repair capabilities. These advanced tools revolutionize traditional methods, offering precision and efficiency in auto frame repair. By integrating such systems, shops can streamline their processes, ensuring consistent and accurate measurements every time. This technology enables technicians to quickly assess damage, identify restoration requirements, and provide customers with transparent estimates – a significant advantage over manual methods.

To maximize the benefits, regular calibration and training are essential. Auto body shop owners should invest in comprehensive training programs for their staff, equipping them with the skills to operate these sophisticated machines effectively. Additionally, staying updated on software upgrades and new features ensures that the computerized frame measurement system remains a powerful asset in the competitive landscape of modern auto repair, ultimately contributing to improved customer satisfaction and retention in car dent repair services.

Computerized frame measurement tools have revolutionized real-time diagnostics across manufacturing and construction industries. By swiftly and accurately measuring frame dimensions, these advanced systems offer significant advantages such as enhanced efficiency, reduced errors, and improved product quality. As organizations seek to optimize their processes, implementing and optimizing computerized frame measurement systems becomes a strategic imperative. This technology not only streamlines operations but also enables data-driven decision-making, ultimately driving competitiveness in today’s digital era.