Mercedes unibody repair is crucial for safety and structural integrity. Advanced engineering and materials create a sophisticated design that differs from traditional body-on-frame structures. Rigorous verification using NDT technology ensures precise alignment and maintains vehicle safety standards post-repair, addressing collision or bumper damage. Skilled technicians and regular quality control reports guarantee optimal vehicle condition and adherence to stringent safety specifications.

Mercedes unibody repair is a specialized process that demands precision and expertise. This article delves into the intricate details of verifying structural quality control reports for Mercedes unibody repairs, ensuring optimal integrity. We explore the significance of understanding the vehicle’s unique unibody structure and highlight the meticulous steps involved in assessing its repair. By adhering to stringent protocols, technicians can guarantee that Mercedes vehicles maintain their renowned safety and performance standards after repairs.

- Understanding Mercedes Unibody Structure and Its Significance

- The Process of Verifying Unibody Repair Quality

- Ensuring Optimal Structural Integrity After Repairs

Understanding Mercedes Unibody Structure and Its Significance

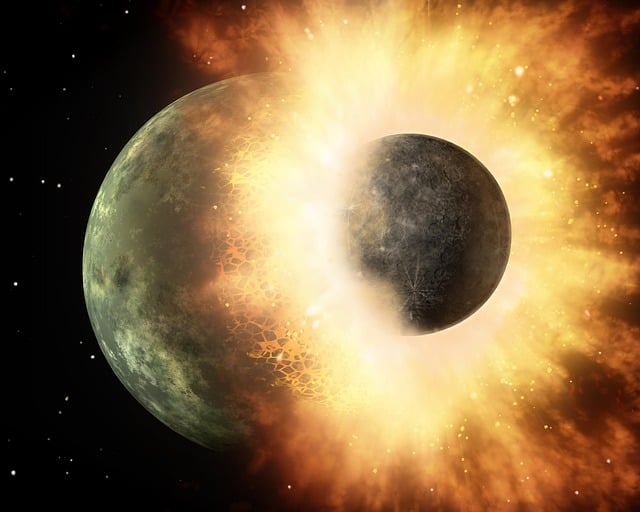

The Mercedes unibody is a complex structural system that combines precision engineering and advanced materials to ensure superior safety and performance. This integral part of Mercedes vehicles forms the backbone, offering protection to occupants during collisions while also maintaining the vehicle’s structural integrity. Understanding its intricate design and significance in overall vehicle stability is paramount when discussing Mercedes unibody repair.

The unibody structure, a departure from traditional body-on-frame designs, offers several advantages in automotive collision repair. Its monolithic construction allows for better energy absorption and distribution during accidents, reducing the risk of structural failure. This, in turn, preserves the vehicle’s overall safety ratings and reinforces the importance of proper repairs to restore its structural quality. Ensuring that any Mercedes unibody repair adheres to factory standards is crucial to maintain this vital system’s integrity and deliver a safe driving experience.

The Process of Verifying Unibody Repair Quality

The process of verifying Mercedes unibody repair quality involves a meticulous sequence of steps designed to ensure structural integrity and precision. After completing the necessary frame straightening or car restoration procedures, technicians employ advanced technology for non-destructive testing (NDT) to assess the repair’s accuracy. This includes utilizing specialized equipment like laser scanners and 3D measurement systems that capture detailed data points across the unibody’s surface, comparing them against original design specifications.

Through this meticulous analysis, collision centers can verify that each component has been precisely aligned and returned to its pre-collision dimensions. Furthermore, structural quality control reports provide a comprehensive record of the repair process, detailing every adjustment made and ensuring transparency for both the technician and the vehicle owner. This rigorous verification is crucial in maintaining the unibody’s strength and safety, ultimately contributing to the overall reliability of the Mercedes vehicle post-repair.

Ensuring Optimal Structural Integrity After Repairs

After a Mercedes unibody repair, ensuring optimal structural integrity is paramount to guarantee the safety and performance of the vehicle. The unibody, which combines the frame and body panels, must be accurately aligned and all components securely fastened to prevent future issues. Skilled technicians utilize advanced equipment during the repair process to restore the original precision and stability of the car’s structure.

Regular structural quality control reports play a crucial role in this process, verifying that each Mercedes unibody repair meets stringent industry standards. These reports assess the overall integrity of the vehicle, including measurements, alignment, and damage assessment. By adhering to these rigorous protocols, automotive restoration specialists can effectively address any residual effects from car collision repair or bumper repair, ensuring the vehicle returns to its optimal condition and safety specifications.

Mercedes unibody repair is a meticulous process that demands precision and expertise. By implementing structured quality control reports, repair shops can ensure the restored vehicle retains its original structural integrity. This rigorous verification method not only guarantees the safety of Mercedes owners but also upholds the brand’s reputation for superior craftsmanship. With proper care and expert handling, even after an incident, a Mercedes can return to its former glory, retaining its unique unibody structure that defines its sleek and robust design.