Tesla's aluminum welding certification program ensures precise and integral welds for all components, enhancing structural integrity and aesthetic accuracy in repairs. This rigorous process mirrors Tesla's commitment to eco-friendly materials, safety, and durability, making its vehicles reliable choices for years to come. Adherence to these standards is vital for auto shops specializing in Tesla repairs, ensuring seamless integration without compromising safety or performance.

Tesla’s commitment to innovation extends to its aluminum welding processes, as evidenced by their recent push for certification. This article delves into how Tesla’s aluminum welding standards enhance vehicle safety and longevity. By understanding these rigorous protocols, we explore the significance of certification in ensuring the structural integrity and reliability of Tesla vehicles over time. Discover why this advancement is a game-changer for the automotive industry.

- Understanding Tesla's Aluminum Welding Standards

- The Role of Certification in Vehicle Safety

- Longevity and Reliability: Benefits for Tesla Vehicles

Understanding Tesla's Aluminum Welding Standards

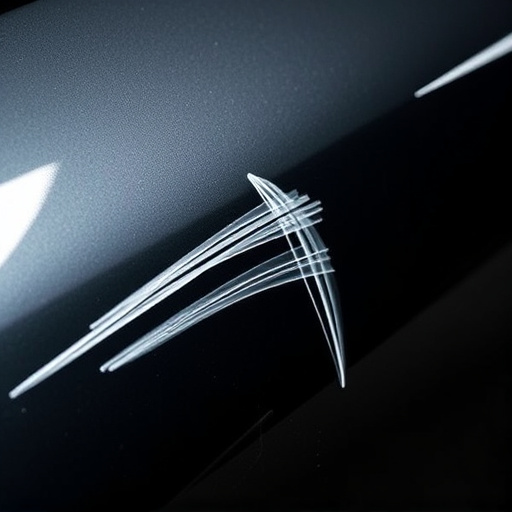

Tesla’s commitment to innovation extends beyond electric motors and advanced software; it also encompasses its manufacturing processes, particularly when it comes to vehicle safety. Central to this is the brand’s adherence to stringent aluminum welding standards. Obtaining a Tesla aluminum welding certification isn’t merely about meeting industry benchmarks; it ensures that every component of a Tesla vehicle, from the chassis to intricate exterior panels, is joined with precision and integrity.

This rigorous standard encompasses not only the technical aspects of welding but also aligns with the company’s eco-conscious ethos by promoting lightweight materials. For auto repair shops specializing in Tesla or those tackling car damage repair involving these vehicles, understanding and adhering to these standards is paramount. It ensures that repairs are not only aesthetically pleasing, matching the vehicle’s original bodywork, but also structurally sound, contributing to the long-term safety and performance of the electric vehicle.

The Role of Certification in Vehicle Safety

In today’s automotive landscape, where safety is paramount, certification plays a pivotal role in ensuring the structural integrity of vehicles. The Tesla aluminum welding certification is a significant step towards fortifying vehicle safety over the long term. This rigorous process guarantees that welds on Tesla vehicles meet stringent industry standards, enhancing overall durability and reliability.

For auto collision centers and automotive collision repair professionals, adhering to such certifications is crucial when conducting collision damage repair. It ensures that replacement parts, including aluminum components, are seamlessly integrated into the vehicle’s structure without compromising safety. This meticulous approach not only guarantees optimal performance but also reduces the risk of future structural failures, making Tesla vehicles safer on the road for all passengers.

Longevity and Reliability: Benefits for Tesla Vehicles

The Tesla aluminum welding certification program is a game-changer when it comes to ensuring the longevity and reliability of their vehicles. By implementing rigorous standards for aluminum welding, Tesla guarantees that every car body restoration and repair process adheres to the highest safety protocols. This commitment results in superior structural integrity, a key aspect that protects against potential hazards over time.

Compared to traditional steel bodies, aluminum offers lightweight benefits, enhancing fuel efficiency and performance. The Tesla certification ensures these advantages are maintained throughout the vehicle’s lifecycle, even after repairs or hail damage repair. This means car owners can expect their Tesla vehicles to not only withstand the test of time but also maintain optimal safety features, making them a reliable choice for years to come.

Tesla’s aluminum welding certification is a significant step towards ensuring long-term vehicle safety and reliability. By adhering to stringent welding standards, Tesla guarantees that their vehicles are built with precision and durability in mind. This certification plays a pivotal role in fostering consumer confidence, knowing that every component, including the use of lightweight aluminum, meets the highest quality and safety criteria. With these measures in place, Tesla continues to lead the way in automotive innovation, delivering not just cutting-edge technology but also vehicles built to last.