Mercedes crash sensor replacement is a critical safety measure requiring precise installation. Damage from accidents or frame straightening necessitates replacing sensors to OEM standards for accurate data transmission and reliable airbag deployment. The process involves careful disengagement of damaged sensors, meticulous new sensor installation with specific torque requirements, reattachment of panels, and rigorous testing. For optimal results, it should be performed by a qualified mechanic to ensure safety and performance integrity.

Looking to replace your Mercedes crash sensor? This comprehensive guide breaks down the process, offering insights into the crucial functions of these safety components. We’ll walk you through each step, from understanding the sensor’s role in your vehicle’s safety system to securing it with precise torque specifications. By following these detailed instructions, you’ll ensure a safe and effective Mercedes crash sensor replacement.

- Understanding Mercedes Crash Sensor Functions

- Step-by-Step Replacement Process & Tools

- Torque Specifications for Secure Mounting

Understanding Mercedes Crash Sensor Functions

Mercedes crash sensors play a critical role in enhancing passenger safety by detecting and responding to vehicle collisions. These sophisticated devices are designed to quickly assess the severity of an impact, enabling the deployment of airbags and triggering emergency services if necessary. Understanding the functions of these sensors is essential when considering a Mercedes crash sensor replacement. The process involves more than just swapping out the old for new; it requires precise torque specifications and careful mounting to ensure optimal performance and reliability in the event of another collision.

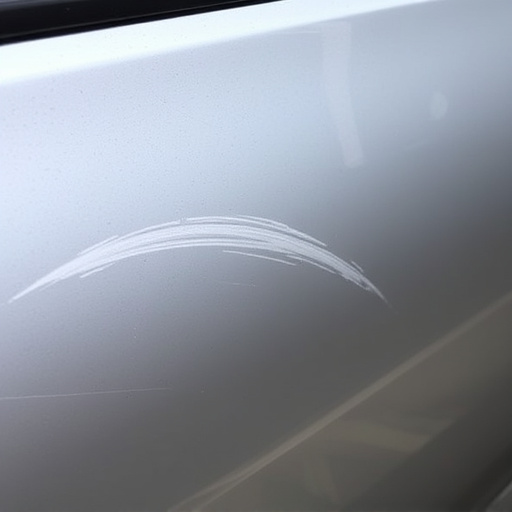

Properly installed and calibrated, these sensors work in tandem with the vehicle’s safety systems to minimize the impact of a car collision or vehicle dent repair. In cases where significant structural damage occurs, such as during frame straightening, it becomes even more crucial to have replacement sensors that align precisely with original equipment manufacturer (OEM) standards. This guarantees that the sensor can accurately detect and transmit data, ensuring the safety features function correctly in the event of a subsequent accident.

Step-by-Step Replacement Process & Tools

The Mercedes crash sensor replacement process involves a series of precise steps to ensure optimal functionality and safety. It’s recommended that this task be carried out by a qualified mechanic or in a professional vehicle body shop, given its critical nature. First, the damaged sensor needs to be located, which often requires removal of the surrounding components, such as plastic panels or fenders, using specialized tools designed for car dent removal. Once accessible, the old sensor is carefully disengaged from its mounting points, taking note of any specific torque requirements during this process.

Next, the replacement sensor is installed, ensuring proper alignment and a secure fit. This may involve tightening bolts to the recommended torque specifications provided by Mercedes-Benz or consulting their official guidelines. After the new sensor is in place, reattachment of the removed panels can commence, followed by thorough testing to verify that all systems are functioning correctly. It’s crucial to note that incorrect installation could compromise airbag deployment, so meticulous attention to detail is paramount during this step-by-step replacement process.

Torque Specifications for Secure Mounting

When it comes to Mercedes crash sensor replacement, achieving secure mounting is paramount for ensuring optimal performance and reliability. Torque specifications play a crucial role in this process, as they determine how tightly the sensors are fastened to their designated locations. Following the manufacturer’s recommended torque values guarantees that the sensors are securely held in place, preventing any potential movement or loosening during an impact event. This is particularly important for maintaining the integrity of the vehicle’s safety systems.

For a successful Mercedes crash sensor replacement and subsequent vehicle restoration, understanding and adhering to the correct torque specifications is essential. This meticulous step ensures that the collision center or fleet repair services can deliver top-notch repairs, enhancing the overall safety and performance of the vehicle.

Mercedes crash sensor replacement is a crucial process that requires precision and adherence to specific torque specifications. By understanding the functions of these sensors, following a detailed replacement process, and ensuring secure mounting through the right torque values, vehicle safety can be effectively maintained. This ensures that in the event of an accident, the sensors perform optimally, facilitating swift deployment of safety features and potentially saving lives.