Plastic welding collisions in auto repair are addressed through skilled technicians using specialized tools and training. Accurate equipment calibration prevents defects, while sanding after welding ensures a flawless finish. Meticulous attention to detail, including inspection and buffing, achieves high-quality repairs. Specialized finishing tools and patience ensure professional welds that seamlessly integrate with original vehicle components.

Discover the best practices for achieving flawless results with sanded and finished plastic welds. This comprehensive guide delves into the intricacies of plastic welding collisions—their causes and effective prevention strategies. From understanding the fundamental techniques to mastering specific tools and finishing tactics, we equip you with the knowledge to perfect your craft. By adhering to these best practices, you’ll ensure robust, aesthetically pleasing plastic welds that meet the highest industry standards.

- Understanding Plastic Welding Collisions: Causes and Prevention

- Tools and Techniques for Effective Sanding

- Achieving Smooth Finish: Best Practices for Finishing

Understanding Plastic Welding Collisions: Causes and Prevention

Plastic welding collisions are a common issue in the automotive industry, especially during bumper repair or other auto body work. Understanding the causes is key to preventing these defects. One primary reason is improper alignment during the welding process. When joining two plastic parts, precise positioning is crucial as any misalignment can lead to weak bonds and eventual failure at the weld site. Regular calibration and maintenance of welding equipment, including robotic systems, are essential practices to ensure accurate alignment.

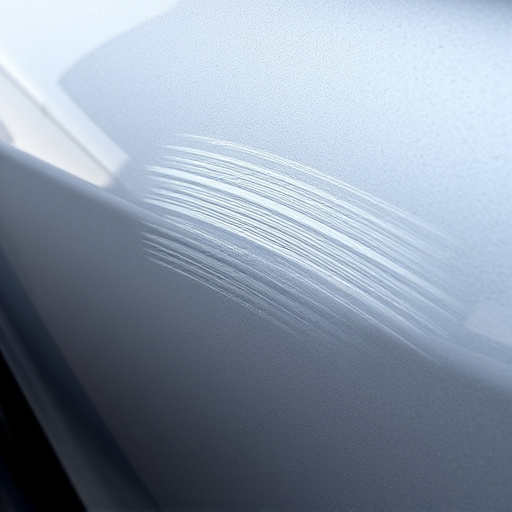

Additionally, using the right techniques and materials is vital for minimizing collisions. For instance, when conducting a scratch repair, skilled technicians employ specialized tools and filler materials designed for plastic to create seamless bonds. Proper training and experience are indispensable in mastering these techniques, guaranteeing robust welds that mimic the original structure, thus preventing future collision-related issues in auto repair shops near you.

Tools and Techniques for Effective Sanding

Sanding is a critical step in achieving a smooth and professional finish after plastic welding. The right tools and techniques are essential to ensure precision and efficiency. For effective sanding, consider using a variety of sandpaper grits, starting with coarse for initial shaping and transitioning to finer grits as you refine the surface. A power sander or a palm sander can facilitate quick work, but be mindful of overheating sensitive plastic materials.

When it comes to techniques, approach the weld area gently, avoiding excessive pressure that could damage the surrounding material. Use circular motions or follow the grain direction for optimal results. For intricate or tight spaces, hand sanding may be more suitable. Remember, the goal is a paintless dent repair and seamless automotive body work, so meticulous attention to detail is key.

Achieving Smooth Finish: Best Practices for Finishing

Achieving a smooth finish is a critical aspect of plastic welding collision repair and bumper repair processes. After completing the initial weld, it’s essential to employ best practices for finishing to ensure the final product meets high-quality standards. Start by carefully examining the welded area for any imperfections, such as visible weld beads or uneven surfaces. Fine-grit sandpaper can be used to gently buff away these markings, creating a seamless transition between the welded and adjacent plastic surfaces.

For intricate automotive repair services, consider using specialized finishing tools designed for precision work. These tools can help achieve a consistent and polished finish on complex car collision repair projects. Remember, patience is key; take your time to ensure each step is done correctly, leading to a professionally refinished weld that seamlessly integrates with the vehicle’s original components.

When it comes to mastering the art of plastic welding, understanding potential collisions and implementing the right sanding and finishing techniques are key. By preventing plastic welding collisions through meticulous preparation and utilizing advanced tools and materials, you can achieve seamless, high-quality results. Following best practices for sanding ensures a smooth surface, while adopting effective finishing methods creates a professional look. These practices not only enhance the aesthetics but also the structural integrity of your welds, making them suitable for various applications across industries.