The PDR process (Paintless Dent Repair) is a modern, efficient car repair technique using specialized tools to remove dents without damaging paint, preserving vehicle aesthetics. It enhances operational efficiency, reduces costs and repair times, minimizes environmental impact, and maintains resale value—gaining popularity in luxury vehicle sectors and among businesses for its proven success in improving customer experiences and driving profitability.

“Discover how the PDR (Process Design and Optimization) process is transforming businesses across industries. This article explores the compelling reasons driving organizational investment in PDR, highlighting its significant benefits. We’ll delve into how this strategic approach enhances operational efficiency, cuts costs, and drives growth. Through case studies of successful implementers, we’ll showcase real-world examples of PDR’s transformative power. By understanding the PDR process, businesses can unlock their full potential for success.”

- Understanding the PDR Process and Its Benefits for Businesses

- How PDR Can Enhance Operational Efficiency and Cost Savings

- Case Studies: Successful Implementers of the PDR Process

Understanding the PDR Process and Its Benefits for Businesses

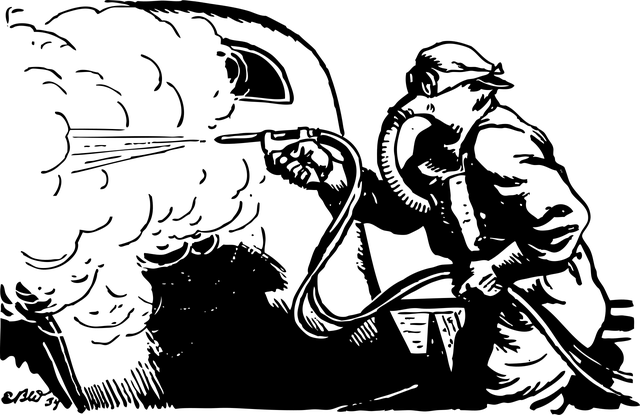

The PDR process, or Paintless Dent Repair, is a cutting-edge technique revolutionizing the way businesses handle car scratch repair and collision repairs. Unlike traditional methods that involve sanding and repainting, PDR uses specialized tools to gently push out dents from the car’s surface, leaving no trace of damage. This not only preserves the vehicle’s original finish but also significantly reduces repair times and costs.

For businesses offering mobile collision repair services or in-house car paint repair facilities, adopting the PDR process offers a multitude of benefits. It streamlines operations by eliminating the need for complex preparation and finishing steps, allowing technicians to perform high-quality repairs on-site and in less time. Moreover, the process is environmentally friendly, as it minimizes waste and the use of harmful chemicals typically associated with traditional paint repair methods.

How PDR Can Enhance Operational Efficiency and Cost Savings

The PDR process, or Paintless Dent Repair, is transforming the automotive industry by offering a cost-effective and time-saving solution for car bodywork services. This innovative technique has gained significant traction among businesses, especially in the luxury vehicle sector, with brands like Mercedes-Benz embracing it as an efficient alternative to traditional dent repair methods. By utilizing specialized tools and techniques, PDR allows for precise removal of dents and dings without the need for extensive paintwork or body panel replacement. This results in substantial cost savings for both businesses and consumers, as less labor is required and there’s minimal material waste.

Moreover, operational efficiency is significantly enhanced during the repair process. With PDR, vehicles can remain on the lot or in the shop for shorter periods, reducing downtime for customers and maximizing workshop productivity. The ability to restore cars to their original condition without extensive repairs makes it an appealing option for car body restoration, ensuring that vehicles maintain their resale value and aesthetic appeal. This is particularly advantageous for fleet managers and dealership owners looking to keep their vehicle inventory in top shape while minimizing operational costs.

Case Studies: Successful Implementers of the PDR Process

Many businesses are turning to the PDR process for its numerous benefits, as evidenced by several successful case studies. Companies across industries have adopted this innovative approach to auto bodywork and collision repair, with remarkable outcomes. One notable example is a leading automotive dealership that implemented PDR as part of their customer service strategy. By offering on-site vehicle body repair through the PDR process, they significantly reduced customer wait times and increased satisfaction levels. This not only enhanced their reputation but also led to increased sales and repeat business.

Another successful story comes from a small, independent auto shop that specialized in collision repair. By embracing the PDR method, they were able to streamline their operations, reduce labor costs, and turn around repairs much faster. The shop’s customers appreciated the convenience and quality of service, leading to positive reviews and word-of-mouth recommendations. These case studies demonstrate how businesses can improve efficiency, customer experience, and profitability by adopting the PDR process in their auto bodywork and collision repair services.

The PDR process is emerging as a game-changer for businesses seeking to optimize their operations, enhance efficiency, and achieve significant cost savings. By leveraging this innovative approach, companies can streamline processes, reduce waste, and improve overall productivity. The success stories highlighted in this article demonstrate that investing in the PDR process pays dividends, setting the stage for sustainable growth and a competitive edge in today’s dynamic market.