Computerized frame measurement revolutionizes vehicle repair with unparalleled precision and efficiency. Automating damage assessment, these systems reduce human error, enhance quality control, and streamline repairs, especially for complex tasks like dent removal. By providing real-time data, they improve service quality, boost technician confidence, and ultimately satisfy customers.

Computerized frame measurement is transforming automotive repairs, offering unparalleled precision and confidence. This advanced technology captures accurate data, reducing manual measurements prone to human error. By unlocking precise dimensions and angles, repairs become more consistent and reliable. Automating this crucial step streamlines quality control, enabling mechanics to focus on complex tasks. Embrace computerized frame measurement for efficient, superior results that restore vehicles to their optimal state with enhanced confidence.

- Accurate Data Collection: Computerized Frame Measurement Unlocks Precision

- Reduced Human Error: Boosting Repair Confidence Through Automation

- Efficient Quality Control: Streamlining Processes for Superior Results

Accurate Data Collection: Computerized Frame Measurement Unlocks Precision

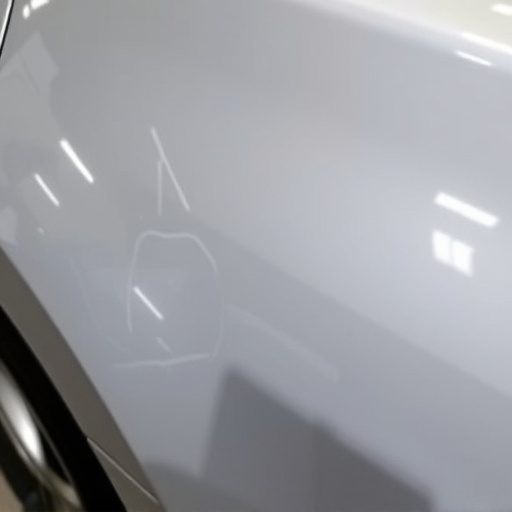

Computerized frame measurement revolutionizes vehicle repair services by offering unparalleled precision and accuracy. Traditional manual measurements often fall short in capturing the intricate details of car bodywork, leaving room for errors that can affect the quality of repairs. With advanced technologies, however, professionals now have a reliable tool to capture precise data, ensuring every angle, curve, and contour is accurately documented.

This innovative approach is especially beneficial for complex tasks like car dent repair. By digitizing frame measurement, technicians can quickly assess damage, determine the extent of the work required, and guarantee repairs that restore the vehicle to its original condition with meticulous detail. The data collected not only enhances the efficiency of car dent repair but also builds confidence in the overall restoration process, providing customers with peace of mind.

Reduced Human Error: Boosting Repair Confidence Through Automation

Computerized frame measurement systems have revolutionized the automotive repair industry, boosting confidence among technicians and customers alike. By automating the process of measuring and analyzing vehicle frames, these advanced tools significantly reduce human error. Traditional manual measurements are prone to inconsistencies and subjective interpretations, leading to potential inaccuracies in repairs.

With computerized systems, every detail is captured with precision, ensuring that even minor imperfections are not overlooked. This level of automation means repairs are more consistent, efficient, and effective. For instance, when dealing with car dent removal or auto glass replacement, these technologies enable technicians to make informed decisions quickly, knowing exactly what needs to be addressed. Moreover, the accuracy extends to tire services, where precise measurements guarantee optimal wheel alignment and handling.

Efficient Quality Control: Streamlining Processes for Superior Results

In the realm of automotive repair, especially after incidents like a fender bender or more extensive autobody repairs, precise and efficient quality control is paramount to ensuring customer satisfaction and maintaining high standards. Computerized frame measurement plays a pivotal role in this process by revolutionizing traditional methods and boosting repair confidence. This advanced technology streamlines processes, enabling technicians to accurately assess and document vehicle damage, resulting in superior outcomes.

By employing computerized frame measurement tools, car body shops can efficiently manage the intricate details of each repair job. These systems provide real-time data, enhancing visibility into the extent of damage, which is crucial for effective planning. This level of precision not only saves time but also minimizes errors, ensuring that every autobody repair meets or exceeds industry standards. The technology offers a systematic approach to quality control, fostering consistency in repairs and boosting the overall confidence of both technicians and clients.

Computerized frame measurement is transforming the repair industry by offering unprecedented precision, reducing human error, and streamlining quality control processes. This technology enhances repair confidence, ensuring more accurate and efficient outcomes. By adopting computerized frame measurement practices, professionals can elevate their standards, satisfy customer expectations, and stay ahead in a competitive market.