Ice damage collision repair presents unique challenges for automotive professionals in regions with icy conditions, requiring specialized techniques to restore structural integrity and original aesthetics of luxury or fleet vehicles, including meticulous painting, advanced diagnostics, paintless dent repair, and high-quality auto glass replacement while managing diverse parts inventory. Ensuring long-term structural integrity and optimal vehicle performance post-repair is critical for safety, historical value, and industry standards adherence.

In the realm of automotive restoration, ice damage collision repair presents unique challenges. When severe winter conditions strike, vehicles often suffer intricate and subtle damage, from cracked windshields to warped body panels. This article delves into the complexities of tackling ice-inflicted damage, focusing on three key aspects: understanding the unique challenges posed by ice, navigating material replacement intricacies, and ensuring structural integrity during the repair process. By exploring these topics, we aim to equip professionals with insights for effective ice damage collision repair.

- Unique Challenges Posed by Ice-Inflicted Damage

- Navigating Complexities of Material Replacement

- Ensuring Structural Integrity After Repairs

Unique Challenges Posed by Ice-Inflicted Damage

Ice damage collision repair presents unique challenges that go beyond the typical automotive repair scope. When a vehicle collides with ice, it often suffers non-conventional damage, such as cracks in the windshield, frozen fluid lines, and distorted metal from the force of impact against frozen surfaces. These types of damages require specialized techniques and materials for effective repairs.

For luxury vehicle repair or fleet repair services, addressing ice-inflicted damage necessitates a thoughtful approach. Automotive repair professionals must consider the structural integrity of components like hoods, fenders, and door panels that may have been distorted by the force of impact against solid ice. Additionally, frozen debris from other vehicles can cause intricate scratches and dents that require meticulous painting and body work to restore the vehicle’s original aesthetic, especially for high-end models.

Navigating Complexities of Material Replacement

When dealing with ice damage collision repair, one of the most significant challenges lies in navigating the complexities of material replacement. This process demands a meticulous approach due to the unique and often specialized nature of automotive components. In regions prone to icy conditions, vehicles are more susceptible to hail damage repair, further complicating matters. The need for high-quality, compatible materials is paramount to ensure not just structural integrity but also the safety of future repairs.

In the realm of ice damage collision repair, fleet repair services often face a unique set of challenges. They must be prepared to handle both individual vehicle repairs and bulk restoration tasks. This necessitates a robust inventory management system that can accommodate a variety of parts, from exterior panels to intricate interior components. Efficient coordination with suppliers is crucial to ensure the availability of authentic, factory-spec materials, contributing to the overall quality of automotive restoration efforts.

Ensuring Structural Integrity After Repairs

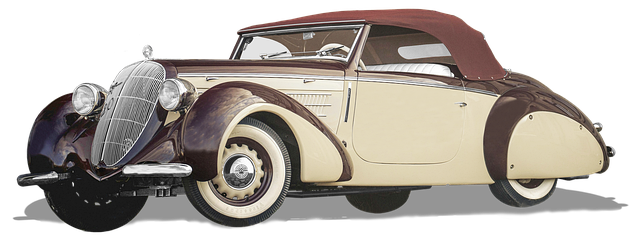

After repairs for ice damage collision, ensuring structural integrity is paramount to guarantee safety and performance of the vehicle. This involves meticulous assessments to identify any hidden damage or weaknesses that could compromise the car’s overall stability. Skilled technicians use advanced diagnostics and manual inspections to verify that all components, from frames and panels to suspension systems, are secure and aligned properly. Restoring a classic car after such incidents demands extra care due to their unique construction and historical value, requiring specialized techniques like paintless dent repair to maintain authenticity and aesthetics.

Additionally, auto glass replacement is a critical step in restoring structural integrity, especially if the windshield or side windows were cracked or shattered during the collision. Modern auto glass installations not only enhance safety by providing impact resistance but also ensure thermal insulation and noise reduction, contributing to improved driving dynamics and passenger comfort. Ensuring these repairs meet industry standards and use high-quality materials is essential for long-term structural integrity and optimal performance of the vehicle post ice damage collision repair.

Ice damage collision repair presents unique challenges, from navigating complex material replacements to ensuring structural integrity. Understanding these complexities is crucial for effective and safe repairs. By implementing robust strategies in each of these areas, auto body shops can enhance the quality and longevity of their work, ultimately providing customers with reliable and safe vehicles following ice-related incidents.