TIG welding collision systems revolutionize automotive body repairs, ensuring precision and strength through advanced testing of welded components. These systems enhance structural integrity for both modern and classic vehicles, effectively fixing scratches and damage with bonds matching or exceeding original metal strength. Widely used in collision repair centers, they extend vehicle lifespans, reduce costs, and provide visually appealing, durable repairs.

TIG welding collision systems are transforming structural integrity in various industries. This advanced technology combines the precision of TIG (Tungsten Inert Gas) welding with integrated collision detection, minimizing defects and maximizing strength. By understanding how these systems work and their real-world applications, we can appreciate their role in enhancing durability across diverse sectors. Explore this innovative approach to welding and its profound impact on structural integrity.

- Understanding TIG Welding and Collision Systems

- Enhancing Structural Integrity Through Precision

- Real-World Applications: Improved Strength and Durability

Understanding TIG Welding and Collision Systems

TIG welding, or Gas Metal Arc Welding (GMAW), is a precision welding process that utilizes a non-consumable tungsten electrode to fuse metal together with the addition of a protective gas and filler material. This highly controlled technique is renowned for its ability to create strong, precise welds in various materials, including steel, aluminum, and titanium. When combined with collision systems, TIG welding becomes an invaluable tool for auto repair shops and classic car restorers, offering a unique approach to enhancing structural integrity.

Collision systems integrated into TIG welding processes are designed to accurately simulate the impact and stress that vehicles may encounter in real-world scenarios, such as accidents or severe weather conditions. These systems use advanced technology to apply controlled forces to welded components, testing their strength and identifying potential weaknesses. For car bodywork, this means ensuring that panel repairs, whether on modern or classic vehicles, meet or exceed the original manufacturer’s standards, resulting in a more robust and reliable structure.

Enhancing Structural Integrity Through Precision

The precision engineering behind TIG welding collision systems is revolutionizing structural integrity in various industries, including automotive body work and car dent removal. These advanced systems employ a controlled collision process, where specialized equipment precisely applies force to weld metal components together. This meticulous approach ensures that each joint is perfectly aligned and secured, eliminating potential weaknesses that often arise from conventional welding methods.

This level of precision is particularly beneficial in addressing car scratches and repairs, as it allows for intricate and accurate fixes. By simulating the original manufacturing process, TIG welding collision systems create bonds that rival or even surpass the strength of the original metal, ensuring a robust and long-lasting repair. This meticulous attention to detail not only enhances structural integrity but also contributes to the overall aesthetic appeal, making it an ideal solution for both functional repairs and cosmetic enhancements in automotive body work.

Real-World Applications: Improved Strength and Durability

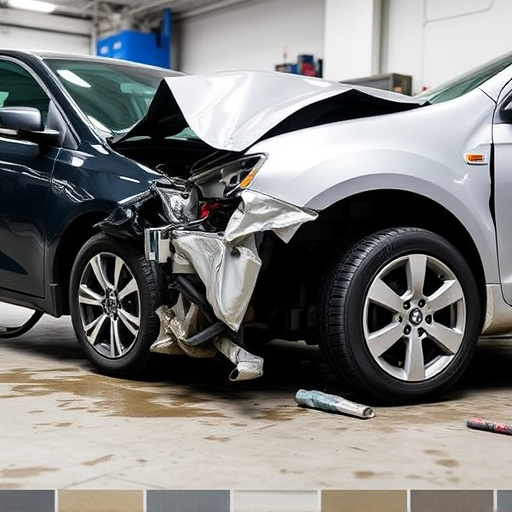

In real-world applications, TIG welding collision systems have proven their mettle in enhancing structural integrity across various industries. These systems are particularly valuable in automotive sectors, where precision and strength are paramount. When a vehicle experiences a fender bender or a more severe collision, the ability to accurately repair and reinforce the damaged areas is crucial. TIG welding offers this precision by allowing skilled technicians to precisely join metal components, ensuring that the structural integrity of the vehicle is restored without compromising on durability.

The result is not just a visually appealing repair but also a robust one. In collision repair centers, TIG welding techniques are employed to mend panels, frames, and other critical parts, extending the lifespan of vehicles and reducing the need for frequent replacements. This durability translates into cost savings for both owners and repair facilities, making TIG welding collision systems an indispensable tool in vehicle collision repair.

TIG welding collision systems represent a significant advancement in structural integrity, offering unparalleled precision and strength. By seamlessly integrating collision detection into the welding process, these systems ensure robust connections in various industries. This technology not only enhances overall structure durability but also promotes efficient, safe, and precise welding, making it an indispensable tool for modern metal fabrication.