Digital frame measuring tools are essential for automotive businesses, offering precision, efficiency, and enhanced quality control. Software solutions streamline processes with user-friendly interfaces, 3D modeling, and cloud collaboration. Accuity's advanced technology excels in Mercedes Benz collision repair, balancing ease of use with high performance for optimal results.

In today’s digital era, accurate frame measuring is essential for various industries. This article explores the options available in digital frame measuring technology, comparing both software and hardware solutions. We begin by understanding the diverse needs of users, from graphic designers to manufacturers. Then, we delve into software solutions, highlighting their features and advantages. Subsequently, we analyze hardware options, focusing on accuracy versus convenience with a close look at accuity and user experience.

- Understanding Digital Frame Measuring Needs

- Software Solutions: Features and Advantages

- Hardware Options: Accuity and Convenience Compared

Understanding Digital Frame Measuring Needs

Understanding your Digital Frame Measuring needs is a critical first step. Whether you’re in the automotive industry, specializing in auto glass replacement or collision repair services, precise measurements are paramount. Accurate digital frame measuring software and hardware can streamline processes, reduce errors, and enhance efficiency.

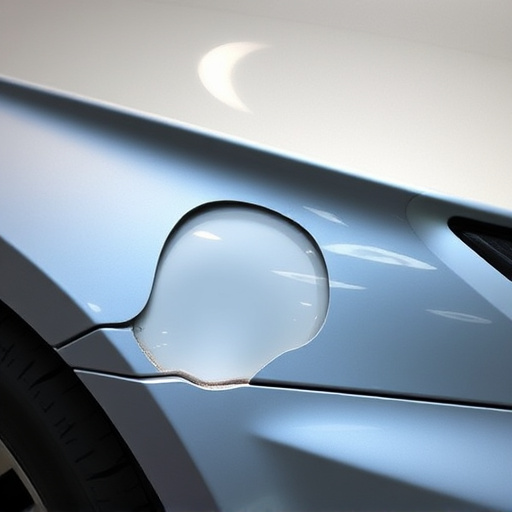

In the realm of digital frame measuring, identifying specific requirements is essential. Consider factors like measurement accuracy, ease of use, compatibility with existing systems, and integration capabilities. For instance, some software solutions offer real-time data synchronization and remote access, which can be invaluable for businesses providing mobile services like dent removal. Ultimately, selecting the right digital frame measuring tools will contribute to improved productivity, better quality control, and enhanced customer satisfaction in both automotive and other industries requiring precise measurements.

Software Solutions: Features and Advantages

Software Solutions offer a suite of features tailored for digital frame measuring tasks, making them indispensable tools in various industries. These programs are designed to streamline the process, providing precise measurements and detailed analyses with just a few clicks. One notable advantage is their user-friendly interfaces, allowing even non-technical users to navigate and utilize their functions effectively. This accessibility ensures that professionals across different sectors can quickly learn and implement these software solutions into their workflows.

Additionally, Software Solutions often come packed with advanced features like 3D modeling, simulation, and visualization capabilities. These tools enable users to perform intricate frame measurements, identify potential issues, and facilitate informed decision-making. Moreover, cloud-based options ensure accessibility from anywhere, enabling remote collaboration and efficient project management—a far cry from the manual, time-consuming methods used in traditional automotive body work, such as mercedes benz collision repair.

Hardware Options: Accuity and Convenience Compared

When it comes to digital frame measuring, hardware options like Accuity and convenience play a significant role in the precision and ease of auto body repair processes, particularly in car bodywork services. Accuity, known for its advanced technology, offers highly precise measurements that are crucial for intricate mercedes benz collision repair tasks. Its digital capabilities enable technicians to capture detailed images and data, ensuring accurate assessments and informed decisions.

On the other hand, while convenience is a key factor in any fender bender repair scenario, it might not always translate into superior measurement accuracy. User-friendly interfaces and quick setup times are definite pluses, but they don’t replace the precision found in dedicated measuring tools. The right balance involves choosing hardware that offers both ease of use and high-level performance to streamline repairs without compromising quality.

When it comes to digital frame measuring, the choice between software and hardware depends on specific needs. Software solutions offer flexibility and a range of features, while hardware options provide accuracy and convenience. For professional applications demanding precise measurements and intricate details, combining both might be the ideal approach. This comprehensive analysis enables users to make informed decisions, ensuring they select the best digital frame measuring tools for their unique projects.