Mercedes panel alignment leverages Original Equipment Manufacturer (OEM) measurement systems to ensure precise repairs, maintaining structural integrity and aesthetic appeal, crucial aspects of the Mercedes brand. These advanced tools guarantee perfect component alignment, from minor dents to extensive body work, enhancing safety features, handling, and overall driving experience through long-lasting vehicle performance and quality assurance.

Mercedes panel alignment is a critical aspect of vehicle fabrication, ensuring precision and quality. This article delves into the meticulous process, focusing on the role of Original Equipment Manufacturer (OEM) measurement systems. We explore how these advanced tools meet Mercedes’ stringent alignment standards, enhancing structural integrity. By understanding the techniques and benefits, we highlight why precise alignment is crucial for both original equipment manufacturers and after-market services, maintaining Mercedes’ renowned craftsmanship.

- Understanding Mercedes Panel Alignment Standards

- The Role of OEM Measurement Systems

- Benefits and Precision in Alignment Techniques

Understanding Mercedes Panel Alignment Standards

Mercedes vehicles are renowned for their precision engineering and meticulous craftsmanship. When it comes to panel alignment, Mercedes sets stringent standards to ensure vehicle safety and aesthetic appeal. These standards guide every step of the repair process in a trusted vehicle body shop, from initial assessment to final inspection.

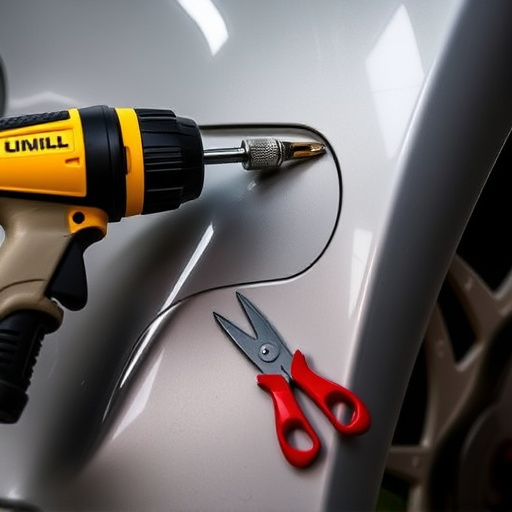

Proper Mercedes panel alignment involves precise measurement and adjustment of various components using OEM (Original Equipment Manufacturer) measurement systems. This ensures that all panels fit seamlessly together, maintaining the vehicle’s structural integrity and original factory finish. Whether it’s a fender repair or vehicle paint repair, achieving accurate alignment is crucial to prevent future issues and maintain the car’s overall appearance, including its glossy finish.

The Role of OEM Measurement Systems

Mercedes panel alignment is a precision process that relies heavily on Original Equipment Manufacturer (OEM) measurement systems. These advanced tools are designed to meet the exacting standards set by Mercedes-Benz, ensuring that every component aligns perfectly with the vehicle’s design. By utilizing OEM systems, technicians can achieve unparalleled accuracy in repairing and restoring car bodies, which is crucial for maintaining the iconic style and integrity of the Mercedes brand.

The integration of these measurement tools into the repair process plays a pivotal role in several aspects of vehicle repair, including panel replacement, dent removal, and scratch repair (car scratch repair). Whether it’s a minor car dent or more extensive car body repairs like fixing a fender bend (vehicle repair), OEM systems provide the blueprint for precise adjustments. This level of accuracy is essential to prevent unsightly gaps or misalignments, guaranteeing that the repaired vehicle looks as good as new. Thus, when it comes to Mercedes panel alignment and car body repair, the use of OEM measurement systems is a game-changer, offering both efficiency and aesthetic excellence.

Benefits and Precision in Alignment Techniques

Mercedes panel alignment techniques have evolved significantly, offering numerous benefits for both original equipment manufacturer (OEM) standards and customer satisfaction. The use of OEM measurement systems ensures precise adjustments, allowing technicians to restore the vehicle’s structural integrity and aesthetic appeal. This precision is critical in achieving proper clearances, aligning components like bumpers and wheels, and ensuring seamless fitment of tires—an essential aspect of comprehensive vehicle repair services.

By employing these advanced alignment methods, repairs extend beyond mere cosmetic fixes. They encompass the entire vehicle, from bumper repair to tire services, ensuring each component functions optimally. This holistic approach not only enhances safety features but also contributes to improved handling and overall driving experience. Consequently, customers benefit from long-lasting vehicle performance and the quality assurance that comes with OEM-standard alignment techniques.

Mercedes panel alignment, when executed with precision using original equipment manufacturer (OEM) measurement systems, is a game-changer for vehicle restoration and customization. By adhering to strict standards, these techniques ensure that every detail aligns seamlessly with Mercedes’ high-quality craftsmanship. The benefits are clear: enhanced precision, faster turnaround times, and superior results, making it an indispensable process in the world of automotive refinishing.