3D vehicle scanning revolutionizes the automotive industry by providing precise digital models for auto body repairs, modifications, and service. This technology enhances accuracy, efficiency, and quality control, streamlining workflows from damage assessment to repair estimates. Integrating 3D scanning requires preparing existing processes, training staff, and creating a detailed integration plan. Standardized protocols ensure consistency and improve customer satisfaction throughout the vehicle lifecycle.

Integrating 3D vehicle scanning into your workflow can significantly enhance automotive design, manufacturing, and repair processes. This cutting-edge technology offers precise digital representations of vehicles, enabling detailed inspections, design refinements, and efficient repairs. In this article, we’ll guide you through the process with sections focusing on understanding 3D vehicle scanning technology, preparing for integration, implementing scans, and optimizing results to streamline your operations with this innovative tool.

- Understanding 3D Vehicle Scanning Technology

- Preparing Your Workflow for Integration

- Implementing and Optimizing 3D Scans in Practice

Understanding 3D Vehicle Scanning Technology

3D vehicle scanning technology is revolutionizing the automotive industry by providing detailed digital representations of vehicles. This advanced process captures millions of data points from a vehicle’s surface, creating accurate 3D models that can be used for various purposes, including auto body repairs and custom modifications. By integrating 3D scanning into your workflow, you gain access to precise measurements and unique design possibilities.

The technology works by using laser scanners or cameras to capture the vehicle’s dimensions and contours from multiple angles. This data is then processed by specialized software to generate a highly accurate 3D model. In an auto body shop or vehicle body shop setting, this means faster and more efficient repairs, precise fitting of custom parts, and improved overall quality control. It also allows for better communication between clients and mechanics, ensuring everyone is on the same page regarding desired modifications.

Preparing Your Workflow for Integration

Before integrating 3D vehicle scanning into your workflow, it’s crucial to prepare your existing processes for this new technology. Begin by assessing your current needs and identifying specific areas where 3D scanning can offer advantages, such as improved accuracy in measurements and damage assessment during autobody repairs or car collision repair. Ensure that your team is trained on the latest 3D scanning equipment and software to maximize efficiency and data accuracy.

Create a clear integration plan by mapping out how 3D scanning will complement existing procedures, particularly in high-precision tasks like luxury vehicle repair. Establish standardized protocols for data capture, storage, and interpretation to streamline your workflow and ensure consistency. By doing so, you’ll be well-prepared to harness the benefits of 3D vehicle scanning, leading to more efficient operations, higher quality outcomes, and enhanced customer satisfaction in both autobody repairs and more intricate luxury vehicle repair jobs.

Implementing and Optimizing 3D Scans in Practice

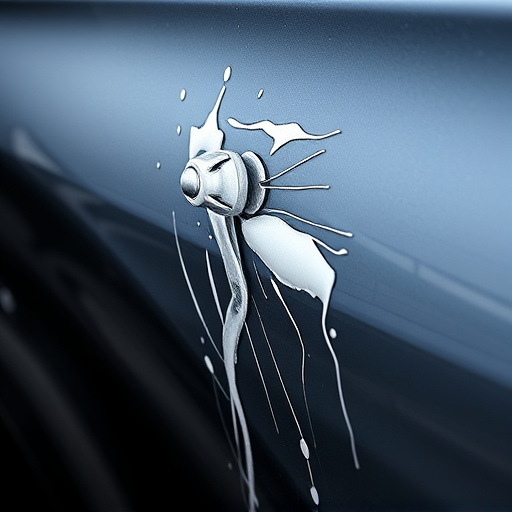

Implementing 3D vehicle scanning into your workflow brings a host of benefits for auto glass repair and automotive repair services. To optimize this technology effectively, start by integrating it at every stage of the vehicle lifecycle—from initial assessment to final restoration. 3D scanning offers an unparalleled level of detail when examining vehicle bodywork, allowing for precise identification of damage, even in hard-to-reach areas. This data can then be used to create accurate repair estimates and work plans.

Moreover, 3D scans serve as valuable records for future reference, ensuring consistent quality standards during ongoing maintenance. By utilizing this technology, auto glass repair specialists and automotive repair services can streamline their processes, reduce human error, and ultimately provide clients with superior results. Remember that continuous optimization through training and investing in high-quality scanning equipment will be key to reaping the full advantages of 3D vehicle scanning.

Integrating 3D vehicle scanning into your workflow can significantly enhance precision, efficiency, and innovation. By understanding the technology, preparing your team, and implementing best practices, you can optimize 3D scans for a wide range of applications. This advanced solution offers a game-changing approach to automotive design, manufacturing, and repair, ensuring accuracy and streamlining processes in today’s digital era.