Frame repair equipment is vital for automotive restoration, offering specialized tools for precise manipulation and realignment of vehicle frames, ensuring structural integrity and safety compliance. Advanced equipment like welding machines and computer-aided design software, combined with skilled technicians, enable accurate repairs after structural damage from accidents or natural disasters. Choosing the right frame repair equipment, based on damage type, make/model, and regulations, is key to successful restoration, worker and user safety, and meeting industry standards in a competitive market.

Frame repair equipment plays a pivotal role in ensuring safety compliance across various industries. This specialized machinery, designed for precision and efficiency, facilitates the intricate process of frame restoration and replacement. By understanding its functionality and impact on safety standards, businesses can make informed decisions when selecting tools. From metal fabrication to structural integrity checks, proper frame repair equipment enhances workplace security, meets regulatory requirements, and ultimately contributes to the longevity of structures.

- Understanding Frame Repair Equipment and Its Functionality

- The Impact of Frame Repair on Safety Compliance

- Selecting the Right Tools for Effective Frame Repair and Regulatory Adherence

Understanding Frame Repair Equipment and Its Functionality

Frame repair equipment is an indispensable toolset for professionals in the automotive industry, particularly those specializing in car body restoration and car bodywork. These specialized tools are designed to accurately and safely manipulate and realign vehicle frames, which serve as the structural backbone of any car. The functionality of frame repair equipment ranges from simple hand tools like wrenches and hammers to complex machinery such as hydraulic presses and laser alignment systems.

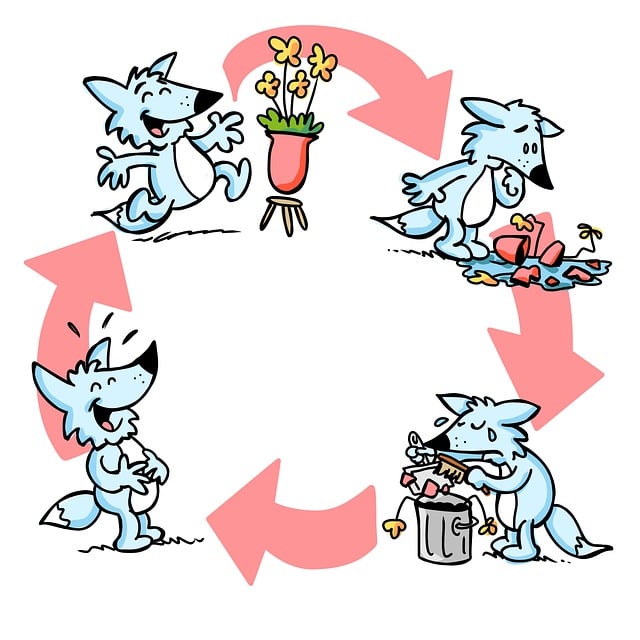

Car paint repair is just one aspect of the broader car body restoration process, and it heavily relies on precise frame manipulation. By utilizing frame repair equipment, technicians can effectively straighten bent or damaged frames, ensuring proper vehicle stability and safety compliance. This meticulous work is crucial in maintaining the structural integrity of vehicles, ultimately contributing to safer driving conditions for everyone on the road.

The Impact of Frame Repair on Safety Compliance

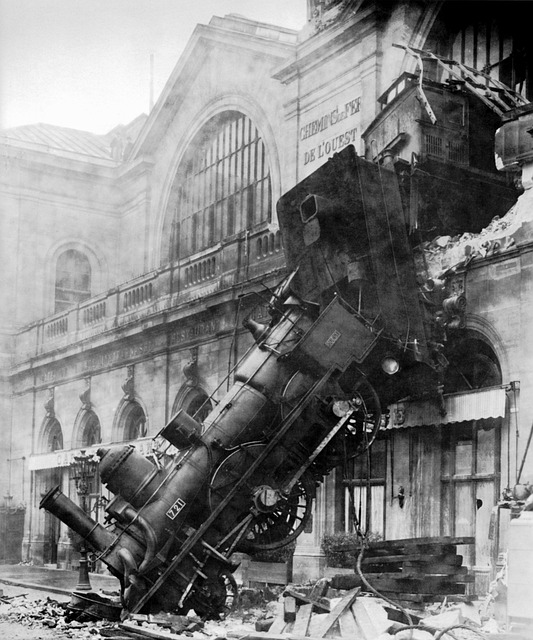

The process of frame repair plays a pivotal role in ensuring safety compliance across various industries, particularly in automotive sectors. This specialized equipment and expertise are essential for restoring structural integrity to vehicles, which is critical for the well-being of occupants and other road users. Frame repairs address issues like damage from accidents or natural disasters, ensuring that cars meet strict safety standards before returning to the road.

Effective frame repair involves advanced tools and techniques, such as specialized welding machines and computer-aided design software. These enable precise adjustments and alignments, correcting any deformities caused by dents or crashes. When combined with skilled technicians, this equipment delivers superior results in auto glass repair, dent removal, and car bodywork services, ultimately contributing to enhanced safety compliance across the board.

Selecting the Right Tools for Effective Frame Repair and Regulatory Adherence

Selecting the appropriate frame repair equipment is paramount for both effective car body restoration and adhering to safety regulations. The right tools ensure precise measurements, accurate adjustments, and seamless panel alignment, resulting in a quality vehicle body repair that meets industry standards. Mechanics should consider factors such as the type of damage, the vehicle’s make and model, and the specific regulatory requirements when choosing their frame repair equipment.

Investments in high-quality equipment not only streamline the repair process but also ensure compliance with safety guidelines, ultimately protecting both workers and end users. Staying up-to-date with the latest advancements in frame repair technology is crucial for car repair services aiming to deliver top-notch results while navigating a competitive market.

Frame repair equipment plays a pivotal role in ensuring safety compliance across various industries. By understanding its functionality and selecting the right tools, companies can effectively address structural issues, mitigate risks, and adhere to regulatory standards. Investing in quality frame repair equipment is not just about maintaining structures; it’s about fostering a safer working environment and promoting long-term operational efficiency.