The evolution of frame repair technology has transformed the automotive industry from traditional manual methods to computerized systems. Historically time-consuming and prone to human error, car dent repair and paint jobs now benefit from advanced software and CAD tools offering unprecedented precision and efficiency. These new systems automate tasks, ensure consistent quality, reduce repair times, and significantly enhance productivity in frame repair and car paint restoration processes, particularly for luxury brands like Mercedes Benz. Despite the adaptability of manual methods, technological advancements address consistency issues and meet the competitive market's demand for timely, reliable services.

The evolution of frame repair techniques has revolutionized the automotive industry. From manual, time-consuming processes, frame repair has embraced computerized systems, marking a significant shift in precision and efficiency. This article delves into the transformative impact of these advanced technologies, exploring their role in enhancing traditional methods. We analyze the advantages, from automation to real-time data analysis, that drive increased productivity and product quality. Furthermore, we discuss the challenges and future prospects of implementing computerized frame repair technology.

- The Evolution of Frame Repair: Traditional Methods vs. Computerized Systems

- – A brief history of frame repair techniques

- – Advantages and limitations of manual/traditional methods

The Evolution of Frame Repair: Traditional Methods vs. Computerized Systems

The evolution of frame repair technology has witnessed a remarkable transformation over the years, marking a clear distinction between traditional methods and the advent of computerized systems. Historically, car dent repair and vehicle paint repairs were manual processes relying heavily on skilled technicians’ expertise. These methods involved time-consuming techniques like hammering, using putty, and applying paint by hand, leaving room for human error and inconsistent results.

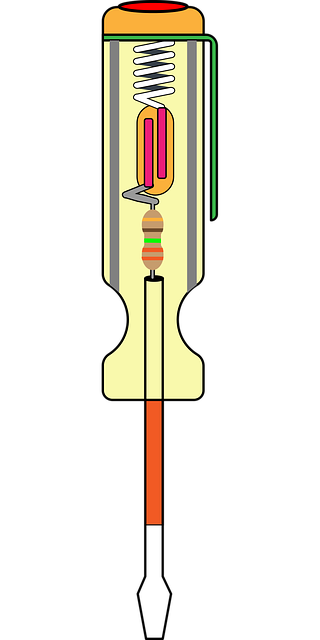

Computerized systems have revolutionized frame repair technology, offering precision and efficiency previously unattainable. Advanced software and computer-aided design (CAD) tools enable technicians to perform complex repairs with remarkable accuracy. In the realm of car paint repair, these systems provide detailed measurements, enabling precise color matching and seamless finishes. By automating repetitive tasks and providing real-time feedback, computerized frameworks ensure consistent quality, reducing the time required for repairs and enhancing overall productivity in the automotive industry.

– A brief history of frame repair techniques

The art of frame repair has evolved significantly over the years, driven by advancements in technology and a growing demand for precision and efficiency. Historically, frame repair involved manual labor, with skilled technicians using hammers, chisels, and various tools to straighten and realign damaged vehicle frames. This process was time-consuming and required immense expertise to avoid further deformation or structural compromise.

As the automotive industry progressed, so did the need for more sophisticated methods. The introduction of computerized systems in frame repair technology has revolutionized the way auto repair services are conducted, particularly in the case of luxury car brands like Mercedes Benz. These advanced systems employ laser scanning, 3D modeling, and precision measuring tools to capture an exact digital blueprint of the vehicle’s frame, enabling technicians to perform more accurate repairs with minimal impact on the overall structure.

– Advantages and limitations of manual/traditional methods

The traditional manual approach to frame repair in the automotive industry has served as the cornerstone for decades. This method relies heavily on skilled technicians who meticulously measure, adjust, and straighten vehicle frames using hand tools and basic machinery. While it requires immense expertise and precision, there are several drawbacks. Manual repairs can be time-consuming, often leading to longer turnaround times for vehicle restoration projects. The process is labor-intensive, making it challenging to maintain consistent quality across various collision repair shops. Moreover, the lack of standardized procedures might result in variations in the final outcome, depending on the technician’s skills and interpretation.

Despite these limitations, traditional frame repair technology remains prevalent due to its adaptability and the vast knowledge base accumulated over years. However, with advancements in technology, computerized systems are now transforming the landscape of frame repair. These digital tools offer enhanced precision, allowing for faster and more efficient vehicle repair processes, particularly in complex collision scenarios. The transition to computerized frame repair technology promises improved consistency and quality in vehicle restoration, catering to the growing demand for timely and reliable services in the competitive automotive market.

Computerized systems have revolutionized frame repair technology, offering precision and efficiency beyond traditional manual methods. By automating tasks like measurement, material selection, and repair techniques, these systems enhance productivity while reducing human error. Embracing computerized solutions not only improves the quality of frame repairs but also paves the way for a more sustainable and advanced industry, catering to the evolving needs of modern vehicle owners.