Corrosion, a natural process causing metal surface damage, poses significant risks to automotive components like bumpers, leading to structural weakening and reduced durability. Effective corrosion protection using coatings (epoxy, polyurethane, vinyl, fiber-reinforced linings) and chemical treatments (inhibitors, additives) is crucial for maintaining vehicle integrity, enhancing safety and reliability, preventing repair needs, extending lifespan, and retaining vehicle value in collision repair shops, especially in challenging climates.

Corrosion remains a significant challenge across various industries, leading to substantial material degradation and costly repairs. This article delves into the world of corrosion protection, exploring common methods employed to safeguard against this destructive force. We begin by understanding the fundamental causes and impact of corrosion, then delve into physical barriers like coatings and liners, followed by chemical treatments featuring inhibitors and additives. By the end, you’ll grasp the multifaceted approach to effective corrosion protection.

- Understanding Corrosion: Causes and Impact

- Coating and Liners: Physical Barriers

- Chemical Treatments: Inhibitors and Additives

Understanding Corrosion: Causes and Impact

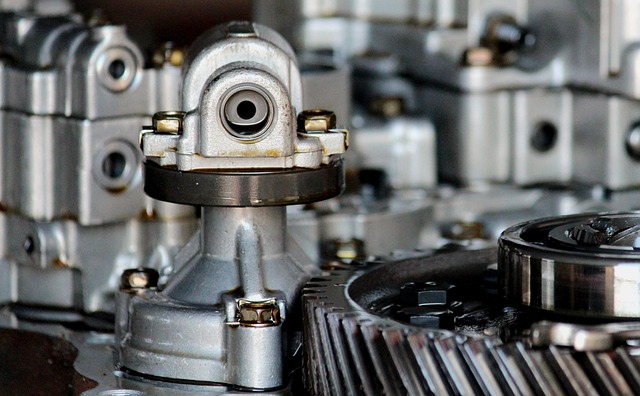

Corrosion is a natural process that occurs when certain materials interact with substances like moisture and oxygen. In the context of corrosion protection, understanding its causes is key to preventing damage. Metal surfaces, commonly used in automotive components such as bumpers, are susceptible to corrosion due to their reactivity. Over time, this can lead to weakened structures, reduced durability, and even structural failure, impacting both functionality and aesthetics.

The impact of corrosion extends beyond mere cosmetic issues. In car repair services and body shop services, it requires significant time and resources for repairs, including bumper repair or complete replacement. Moreover, untreated corrosion can compromise the safety and reliability of vehicles, highlighting the importance of effective corrosion protection measures to preserve the integrity of automotive parts and reduce the need for frequent repairs.

Coating and Liners: Physical Barriers

Coatings and liners serve as physical barriers against corrosion, providing a protective layer over metal surfaces. These materials are designed to withstand harsh environmental conditions, preventing water, moisture, and other corrosive substances from penetrating the metal. In the context of collision repair shops and vehicle body repair services, applying the right coating or liner is crucial for maintaining the structural integrity and aesthetics of repaired vehicles.

Automotive body shops often use specialized coatings like epoxy, polyurethane, and vinyl as well as fiber-reinforced linings to offer superior corrosion protection. These products not only shield against external elements but also protect against internal rust formation, ensuring that vehicle bodies remain in pristine condition even after years of use. Effective coating and lining methods are integral to the longevity and value of a vehicle, making them essential components in modern body shop services.

Chemical Treatments: Inhibitors and Additives

Chemical treatments play a significant role in modern corrosion protection methods. Inhibitors and additives are two commonly used substances that prevent or slow down metal degradation. Corrosion inhibitors act as barriers, forming protective layers on metal surfaces to inhibit the attack of corrosive substances. These can be applied as coatings or incorporated into the material during manufacturing. On the other hand, additives are substances mixed into the base material to improve its resistance to corrosion. They can enhance the natural defense mechanisms of metals and alloys, making them more durable in harsh environments.

In the automotive industry, for instance, these chemical treatments are crucial for maintaining the integrity of vehicles. Professional vehicle repair services often employ frame straightening techniques, which may involve applying specialized corrosion inhibitors to ensure the structural soundness of a car’s frame. Similarly, car paint services utilize protective coatings that not only enhance aesthetics but also serve as a barrier against corrosion, especially in regions with harsh climates.

In today’s world, understanding and mitigating corrosion is more vital than ever for the longevity of materials and structures. From coating technologies to chemical treatments, various effective corrosion protection methods are readily available. By employing physical barriers like coatings and liners, or utilizing chemical inhibitors and additives, we can significantly slow down the degradation process. Staying informed about these strategies enables us to safeguard our surroundings, ensuring the durability and safety of essential infrastructure for years to come.