In today's precision-focused automotive industry, electronic measuring equipment like digital calipers and laser distance meters are transforming repairs and painting. These tools eliminate human error, ensure exact measurements, save time, enhance quality, reduce rework, and foster customer trust, making them a game-changer for accuracy and efficiency in collision services and paintless dent repair.

In today’s precision-driven world, ensuring accuracy is paramount across industries. This is where electronic measuring equipment steps in as a game-changer. Unlike manual methods, these tools offer enhanced precision and digital accuracy, enabling professionals to uncover hidden errors that traditional techniques might miss. Adopting electronic measurement standards isn’t just a choice; it’s a necessary step towards quality assurance, revolutionizing how we approach manufacturing, construction, and more. Let’s explore why.

- Enhancing Precision: The Role of Electronic Measuring Tools

- Uncovering Hidden Errors: Why Digital Accuracy Matters

- Industry Standards: Adopting Electronic Measurement for Quality Assurance

Enhancing Precision: The Role of Electronic Measuring Tools

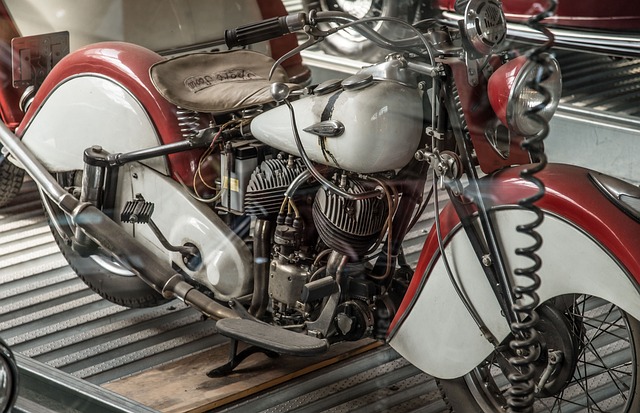

In today’s world where precision is paramount, especially in industries like automotive repair and collision repair services, electronic measuring equipment plays a pivotal role. These tools are designed to deliver accurate, consistent measurements, enhancing the overall quality of work. Unlike traditional methods that might be subject to human error or variability, electronic devices offer unparalleled consistency. For instance, digital calipers provide exacting measurements for intricate dimensions in vehicle body repair, ensuring components fit seamlessly without any margin for mistake.

Moreover, electronic measuring equipment facilitates advanced techniques and technologies, streamlining processes in automotive repair. Laser distances meters, for example, enable rapid and accurate measurements of complex shapes and contours, crucial for precise body repairs. This not only saves time but also minimizes the risk of errors that could lead to costly rework. In essence, embracing these tools is a game-changer, revolutionizing how collision repair services and automotive repairs are conducted, ultimately fostering higher levels of safety, efficiency, and customer satisfaction.

Uncovering Hidden Errors: Why Digital Accuracy Matters

In today’s precision-driven world, even seemingly minor errors can have significant consequences. This is particularly true in industries like paintless dent repair, where accuracy is key to achieving flawless results. Traditional manual methods often introduce hidden mistakes that digital technology helps uncover. Electronic measuring equipment plays a vital role by providing precise, instant readings, enabling professionals in collision centers and car body shops to catch these errors early on.

For instance, when assessing and correcting dents, digital sensors can detect minute variations in a vehicle’s surface, ensuring every detail is accounted for. This level of accuracy not only saves time but also guarantees the integrity of the repair, leading to higher customer satisfaction. By relying on electronic measuring equipment, car body shops can maintain consistent quality standards and build trust with their clients, especially when addressing intricate paintless dent repair tasks.

Industry Standards: Adopting Electronic Measurement for Quality Assurance

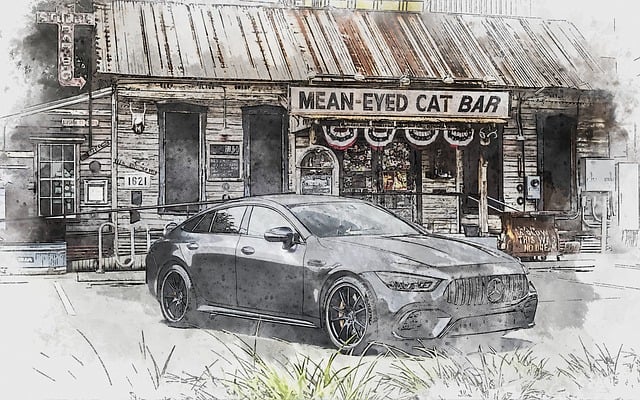

In today’s competitive market, industry standards demand unparalleled accuracy and precision, especially in sectors like car damage repair and auto painting where meticulousness is paramount. Electronic measuring equipment has emerged as a game-changer, revolutionizing quality assurance processes across various industries. Unlike traditional manual methods, these advanced tools offer unsurpassed consistency and repeatability, ensuring that every measurement taken aligns with exacting specifications.

Adopting electronic measurement in car collision repair and auto painting not only enhances productivity but also improves overall product quality. By streamlining work processes and reducing human error, professionals can achieve more consistent results, leading to higher customer satisfaction. This shift towards digital technology is a testament to the industry’s commitment to excellence, setting new benchmarks for accuracy and efficiency in both minor car damage repair and complex auto painting projects.

Electronic measuring equipment plays a pivotal role in ensuring accuracy across various industries. By leveraging digital technology, these tools enhance precision, uncover hidden errors, and adhere to industry standards, ultimately fostering quality assurance. Incorporating electronic measurement into daily practices is not just a trend but a necessity for achieving reliable and consistent results.