Factory seam duplication is a critical automotive manufacturing technique that replicates original seams for structural integrity and aesthetic consistency. The right sealant, especially silicone-based, ensures superior weather resistance and bond strength for exterior seams. Advanced techniques like specialized adhesives, infrared heating, and automated machinery enhance bond strength, prevent separations, and promote longevity in auto collision centers, all while maintaining factory standards.

In the manufacturing industry, the factory seam duplication process is a critical step ensuring product quality and consistency. This article provides essential insights into seamless sealing techniques for optimal results during duplication. From understanding the duplication process to selecting the right sealants and mastering strength-enhancing methods, these tips are vital for achieving high-quality outcomes. By following best practices, manufacturers can guarantee durable and reliable products, meeting industry standards and customer expectations.

- Understanding Factory Seam Duplication Process

- Choosing the Right Sealant for Optimal Results

- Techniques to Ensure Seam Strength and Durability

Understanding Factory Seam Duplication Process

The factory seam duplication process is a meticulous technique employed by automotive manufacturers to create precise and durable bonds during vehicle production. It involves replicating the original seams on auto glass replacement parts, ensuring they match the exact specifications of the vehicle’s design. This meticulous approach is crucial for maintaining structural integrity and aesthetic consistency across various vehicle repair services.

By duplicating seams, manufacturers guarantee that the repaired or replaced components seamlessly integrate into the vehicle, just like the original parts did. This precision is particularly vital in auto repair near me settings, where skilled technicians utilize specialized equipment to match the factory-like finish. The process demands attention to detail and a deep understanding of materials to achieve optimal results, ensuring the safety and reliability of every vehicle.

Choosing the Right Sealant for Optimal Results

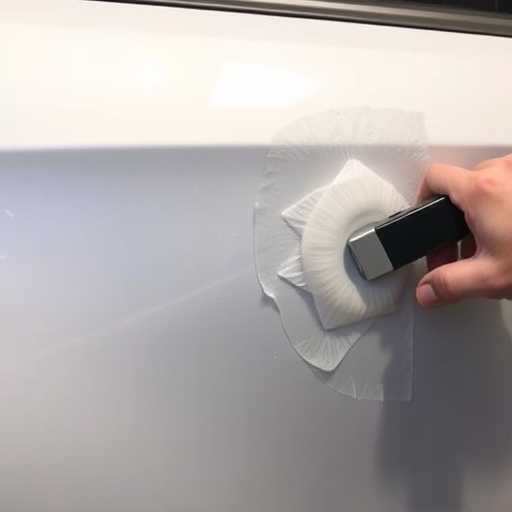

When it comes to factory seam duplication, choosing the right sealant is paramount for achieving optimal results. The ideal sealant should be designed specifically for automotive applications, offering excellent adhesion, flexibility, and durability. This ensures that the seam remains secure under various environmental conditions, preventing leaks and ensuring the longevity of collision repair services and vehicle paint repair processes.

For instance, silicone-based sealants have gained popularity in the industry due to their superior weather resistance and ability to maintain a strong bond over time. These properties are especially crucial when dealing with exterior seams, as they are exposed to constant sunlight, temperature fluctuations, and potential physical damage during collision repairs. By selecting the appropriate sealant tailored to these specific needs, manufacturers can guarantee seamless duplication that matches the quality of original factory standards.

Techniques to Ensure Seam Strength and Durability

To ensure seamless (pun intended) strength and durability during factory seam duplication, several advanced techniques are employed in both industrial settings and auto body repair shops. One such method involves the use of specialized adhesives designed to mimic the structural integrity of the original factory seams, enhancing bond strength and preventing future separations.

Moreover, precise application of heat is crucial for fusing materials seamlessly. In luxury vehicle repair, where precision is paramount, infrared heating tools are often used to achieve consistent results without damaging surrounding components, a technique that translates smoothly to factory seam duplication. Additionally, the utilization of automated machinery for cutting and sealing ensures uniform pressure across the seam, eliminating human error and promoting longevity in auto collision centers.

Factory seam duplication is a complex process that demands precision and the right techniques. By understanding the factory seam duplication process, selecting suitable sealants, and employing effective sealing techniques, manufacturers can achieve robust and long-lasting seams. This ensures product durability, reduces failure rates, and ultimately enhances customer satisfaction. Implement these seamless tips to optimize your factory seam duplication process today.