The traditional auto repair industry's reliance on replacing parts contributes to significant environmental damage and waste. Recycled parts for collision repair offer an eco-friendly alternative, reducing energy consumption, greenhouse gas emissions, and natural resource depletion compared to manufacturing new parts. This practice also provides cost savings while maintaining quality and promotes a circular economy. To ensure sustainability, auto repair businesses should research and select reputable suppliers, verify product certifications, implement material testing, and confirm adherence to original equipment standards for recycled parts collision repair.

In an era focused on sustainability, the auto industry is undergoing a green transformation. Choosing recycled parts for collision repair isn’t just an eco-friendly choice; it’s a strategic move towards a more resilient future. This article delves into the significant environmental impact of traditional auto repair and highlights the numerous benefits of adopting recycled parts. We’ll guide you through the process, from understanding quality assurance to sourcing these parts, offering a practical approach to greener collision repairs.

- Understanding the Impact of Traditional Auto Repair

- Benefits of Using Recycled Parts for Collision Repairs

- How to Source and Verify Quality Recycled Auto Parts

Understanding the Impact of Traditional Auto Repair

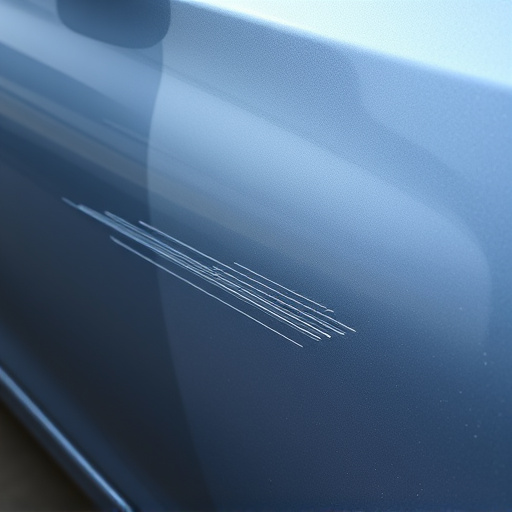

The traditional auto repair industry has long been associated with significant environmental impacts. When a vehicle undergoes collision or damage, the initial response often involves replacing parts rather than repairing or reusing them. This practice contributes to a vast amount of automotive waste, as countless functional components end up in landfills each year. The process of manufacturing new car parts requires extensive resource extraction, energy-intensive processes, and chemical pollutants, all of which leave a substantial carbon footprint.

Choosing recycled parts for collision repair is a proactive step towards sustainability. It encourages the circular economy by reducing demand for virgin materials and minimizing waste generation. A car body shop that prioritizes eco-friendly practices can significantly lower its environmental impact. By opting for reused parts, auto repair near me businesses can contribute to the reduction of automotive scrap, conserve natural resources, and potentially offer cost savings to customers seeking dent repair or other services.

Benefits of Using Recycled Parts for Collision Repairs

Using recycled parts for collision repairs offers numerous advantages, both for the environment and for consumers. One of the key benefits is reduced environmental impact. Recycling materials requires less energy than manufacturing new ones from raw resources, leading to decreased greenhouse gas emissions and conservation of natural resources. This sustainable approach helps in mitigating the ecological footprint associated with traditional car body repair practices.

Additionally, incorporating recycled parts into vehicle restoration processes can result in cost savings for automotive body shops and consumers alike. These parts are often more affordable than their brand-new counterparts, making them an economical choice without compromising quality. Furthermore, the use of recycled materials contributes to a circular economy by extending the lifespan of existing resources, fostering a more sustainable and responsible approach to collision repairs and enhancing the overall efficiency of the automotive industry.

How to Source and Verify Quality Recycled Auto Parts

When considering recycled parts for collision repair, sourcing reliable suppliers is key to ensuring quality and sustainability. Start by researching and selecting reputable dealers specializing in recycled automotive components. These suppliers should adhere to strict standards to guarantee the integrity of their products. Look for certifications or third-party audits that verify the authenticity and quality of the recycled parts.

One effective method to verify quality is through material testing and inspection. This can include examining materials for strength, durability, and corrosion resistance, ensuring they meet industry standards. Additionally, checking for proper manufacturing processes and adhering to original equipment specifications guarantees that recycled parts, such as fender repair or bumper repair components, will provide the same performance and safety as new parts. This approach promotes both environmental sustainability and consumer satisfaction in recycled parts collision repair.

Choosing recycled parts for collision repair isn’t just an eco-friendly decision; it’s a strategic move towards a more sustainable future. By opting for reused components, we reduce the demand for new manufacturing, conserve natural resources, and minimize automotive waste. With proper sourcing and quality verification, recycled auto parts offer a viable and cost-effective solution without compromising on performance. Embracing this practice contributes to a circular economy, ensuring that old cars can find new life while mitigating the environmental footprint of traditional collision repair methods.