The Mercedes Blind Spot Sensor, placed near side mirrors, detects vehicles in the driver's blind spot and provides visual/audible alerts for safer lane changes. Xentry Diagnostics is an advanced tool for collision repair centers to validate sensor alignment, ensuring accurate readings, optimal performance, and enhanced safety standards during vehicle testing and repairs, especially in urban environments. Proper calibration of Mercedes blind spot sensor alignment is crucial for accident prevention and passenger security.

Mercedes’ Blind Spot Sensor (BSS) is a crucial safety feature, detecting vehicles in adjacent lanes. This article delves into the validation process of BSS alignment using Xentry diagnostics, an essential tool for ensuring optimal system performance. We explore the functionality of the Mercedes BSS and why its precise alignment is vital for driver safety. Through detailed testing and calibration procedures, we demonstrate how Xentry diagnostics play a game-changer role in maintaining the BSS’s effectiveness.

- Understanding Mercedes Blind Spot Sensor Functionality

- Xentry Diagnostics: A Tool for Alignment Validation

- Ensuring Optimal Safety: Testing and Calibration Procedures

Understanding Mercedes Blind Spot Sensor Functionality

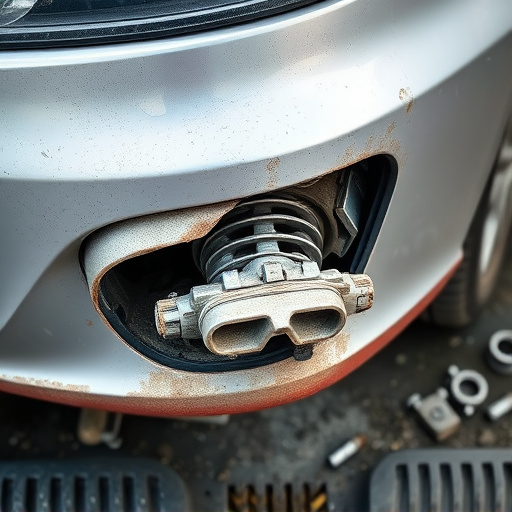

The Mercedes Blind Spot Sensor is a sophisticated piece of technology designed to enhance safety on the road. Its primary function is to detect vehicles in the driver’s blind spot, providing critical information that assists in lane changes and prevents potential accidents. These sensors are strategically placed at the rear of the vehicle, typically near the side mirrors, and work in conjunction with advanced software to monitor surrounding areas. When a vehicle enters the driver’s blind spot, the sensor triggers an alert, often through visual cues on the car’s dashboard or audible signals, ensuring the driver is aware of nearby traffic.

This active safety feature is particularly valuable for drivers who may have limited visibility or are unaware of other vehicles in their vicinity. Proper alignment and functionality of these sensors are essential, as any misalignment could lead to false readings or, worse, a failure to detect nearby cars. Regular maintenance and checks, such as those performed using Xentry diagnostics, help ensure the Mercedes Blind Spot Sensor remains accurate and reliable, contributing to a safer driving experience, especially during maneuvers that involve changing lanes on highways or navigating tight urban streets where visibility is limited, like in a car body shop after hail damage repair.

Xentry Diagnostics: A Tool for Alignment Validation

Xentry Diagnostics serves as a powerful tool for validating the alignment of Mercedes blind spot sensors, offering precise measurements and insights into the sensor’s functionality. This advanced diagnostic software enables collision repair centers and fleet repair services to accurately assess the positioning and performance of the blind spot sensors, ensuring they operate optimally.

By leveraging Xentry, auto painting specialists and technicians can streamline their verification process, confirming that each sensor is correctly aligned and functioning as intended. This meticulous validation step is crucial in maintaining safety standards and preventing any potential issues related to blind spot monitoring, thereby enhancing overall vehicle performance and passenger security.

Ensuring Optimal Safety: Testing and Calibration Procedures

Ensuring optimal safety is paramount when it comes to vehicle technology, especially with features designed to prevent accidents. The Mercedes blind spot sensor alignment plays a crucial role in this regard, and proper testing and calibration procedures are essential to guarantee its effectiveness. Auto repair services that specialize in Mercedes bodywork understand the importance of these steps.

During the testing phase, technicians utilize advanced diagnostic tools, such as Xentry software, to verify the sensor’s accuracy. This involves simulating various driving scenarios, including lane changes and overtakes, to assess how well the blind spot sensors detect surrounding vehicles. Calibration ensures that the system responds accurately to real-world conditions, providing drivers with reliable warnings and enhancing overall safety, especially in bustling urban environments where vehicle body repair might be more frequently needed.

Mercedes blind spot sensor alignment is a critical component of vehicle safety, ensuring drivers are aware of surrounding traffic. Using Xentry diagnostics as a validation tool allows for precise calibration and testing procedures, guaranteeing optimal sensor performance. By leveraging advanced technology, Mercedes owners can experience enhanced safety features, providing peace of mind on the road.